Device and process for preparing aerosol for preventing coal from spontaneous combustion

A technology for preparing devices and aerosols, which is used in safety devices, dust-proofing, mining equipment, etc., can solve the problem that high-level space fires in long-distance goafs cannot be fully effective, fire-fighting materials are difficult to fill in large areas, and coal spontaneous combustion fire effects Not ideal, etc., to achieve good suspension ability, good obstacle bypass ability, and the effect of inhibiting and preventing spontaneous combustion of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

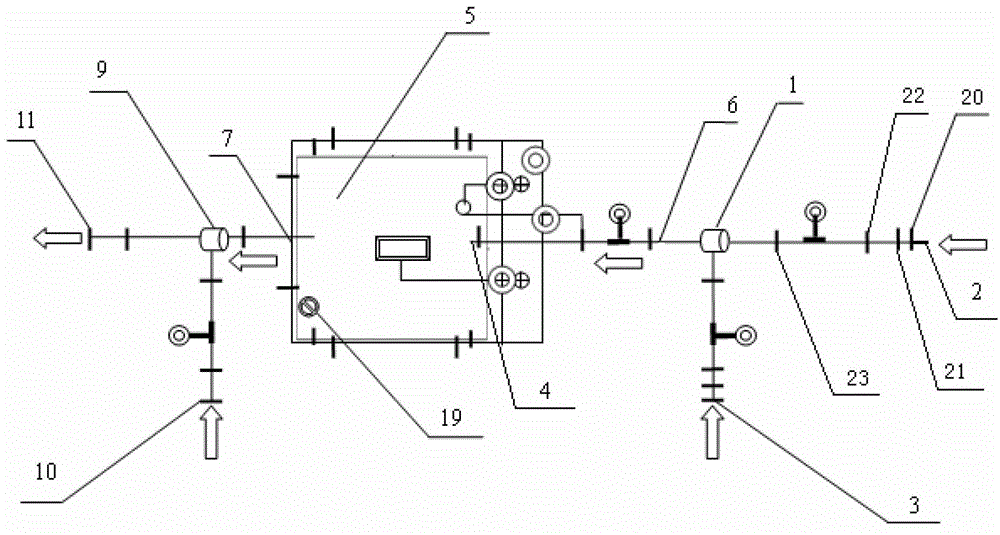

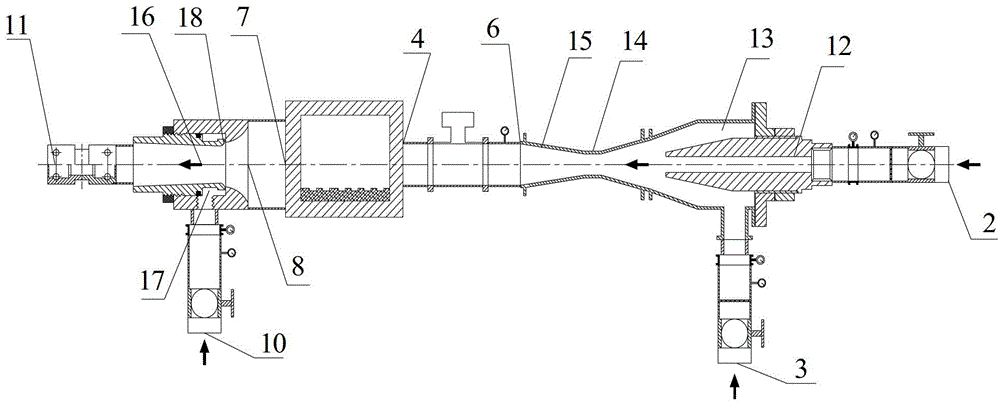

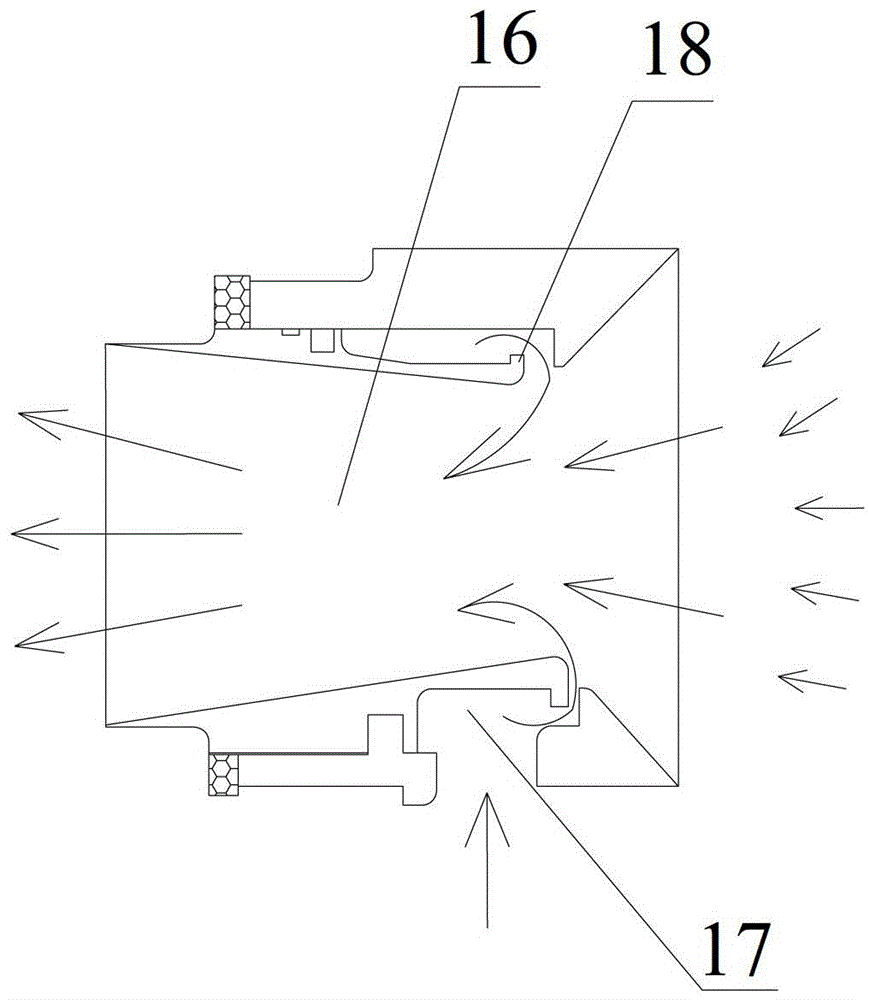

[0031] Such as figure 1 and figure 2 As shown, the aerosol preparation device of the present invention includes a jet proportional device, an aerosol atomization device and a pneumatic delivery device. The jet proportioning device includes a jet proportioner 1, a pressure water inlet 2 connected to the nozzle 12 of the jet proportioner, an inhibitor inlet 3 connected to the suction chamber 13 of the jet proportioner, an output port 6 of the jet proportioner and an aerosol atomization device The liquid inlet 4 is connected; the aerosol atomization device includes an atomization chamber 5 placed in an explosion-proof casing and a power terminal, the atomization chamber is equipped with an integrated ultrasonic atomization plate, and the mist aerosol output port 7 of the atomization chamber It is connected with the suction port 8 of the pneumatic conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com