Diagonal cable pile pulling method and diagonal cable pulling pile system

An oblique cable and anchor cable technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of large investment in lifting equipment, difficult to achieve construction environment, uneven force, etc., to improve the success rate of promotion, reduce Lifting force requirements, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

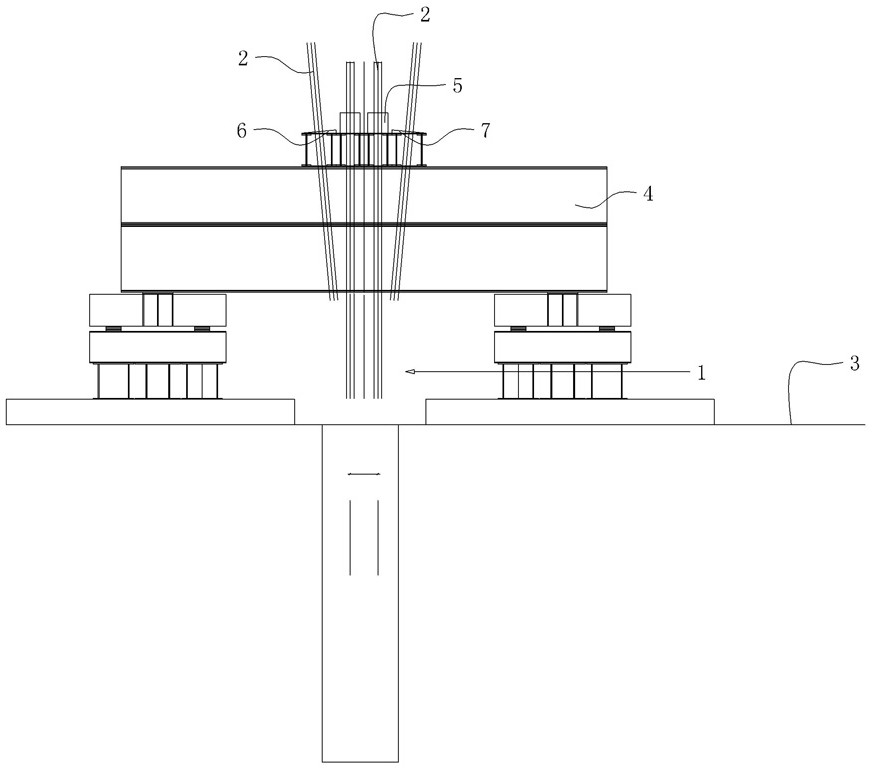

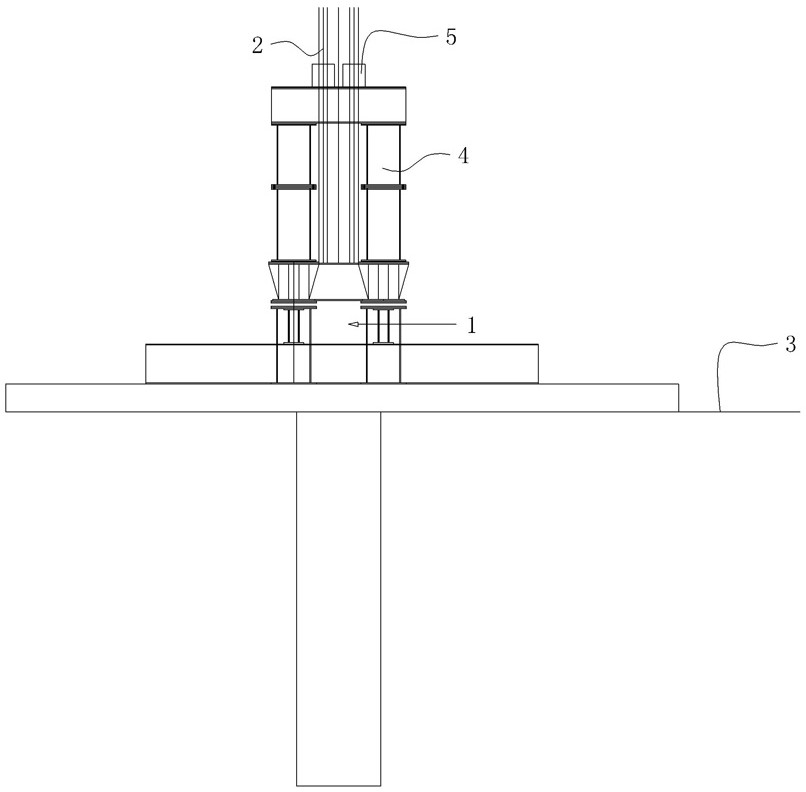

[0043] The method for pulling out the pile with the inclined cable in this embodiment is as follows: figure 1 , figure 2 and image 3 shown, including the following steps:

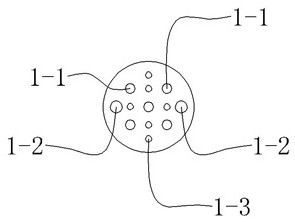

[0044] 1) After investigation and pretreatment, the top of the pile 1 to be pulled is exposed, and at the same time, multiple high-strength anchor cable materials 2 and lifting equipment are installed;

[0045] The pile 1 to be pulled out in this embodiment can be a friction pile buried in the soil, a partially rock-socketed end bearing pile, or an occlusal pile, a cap pile and a driven pile buried at a certain depth below the surface, and so on. The head of a friction pile or end bearing pile is exposed to the ground.

[0046] The anchor cable material 2 in this embodiment can be made of metal hard or soft material. Made of hard metal, such as: bonded strands, prestressed strands, prestressed strands, high-strength steel wires, high-strength steel wire ropes or high-strength steel bars, etc.; also ca...

Embodiment 2

[0080] The method for pulling out the pile with oblique cables of the present embodiment is an improvement on the basis of the first embodiment, and the difference from the first embodiment is:

[0081] The total length of the pile to be pulled 1 to be lifted in this embodiment is 24m, the diameter of the pile is 1500mm, and the height of the pile to be lifted is 7-8m, accounting for 30% of the total length of the pile to be pulled 1 24m. After calculation, the design load of pile pulling force is 8000kN, and the check load is 10000kN.

[0082] In this way, the anchor cable material 2 adopts 4 bundles of CPS15A-12 shear force dispersion anchor cables. Each bundle of CPS15A-14 shear-distributed anchor cables adopts 14-φ15.24 high-strength, low-relaxation steel strands with a tensile strength of 1860MPa.

[0083] The hoisting equipment in this embodiment still adopts the piercing jack, and four sets of 4000kN piercing jacks are selected as the lifting power equipment. Consideri...

Embodiment 3

[0087] The method for pulling out piles with oblique cables in this embodiment is an improvement on the basis of Embodiment 1 and Embodiment 2. The difference from the above-mentioned embodiments is that in step 5) of this embodiment, the hoisting equipment is installed on the working platform 3 on the hoist or winch. The crane or hoist is installed on the reinforced concrete platform, the steel structure frame platform or the combined structure platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com