Elevating machine tool protection door and hydraulic control device thereof

A technology for control devices and protective doors, which is applied in the fields of manufacturing tools, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of lifting devices, difficult to avoid iron filings, accumulation and other problems, and achieve the effect of reliable lifting action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

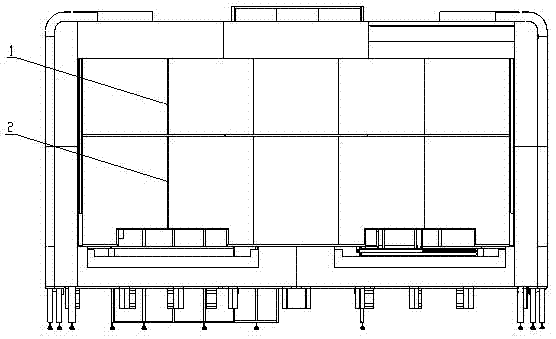

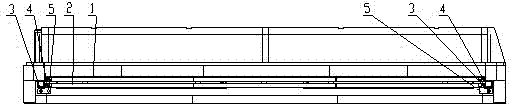

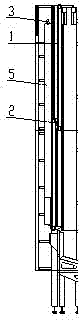

[0025] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0026] In the preferred embodiment of the lift-type machine tool protective door of the present invention, it includes a protective door main body arranged on the machine tool protective cover. The connecting mechanism is fixedly connected with the main body of the protective door, and the driving mechanism is connected with the hydraulic control device. Under the control of the hydraulic control device, the driving mechanism drives the main body of the protective door to move. The sliding mechanisms are respectively located on both sides of the main body of the protective door and at the same time on the protective cover of the machine tool. superior.

[0027] Specifically, the connecting mechanism is a connecting bracket 5, and the piston rod of the hydraulic cylinder 3 is connected to the connecting bracket. see figure 1 As shown, the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com