A revolving door table of a tube expander

A technology of rotating workbench and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc. It can solve the problems of low production efficiency of tube expanders, long time required for a single workpiece, and high work intensity of operators. , to achieve the effect of improving continuous production efficiency, simple structure, and adjustable action rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

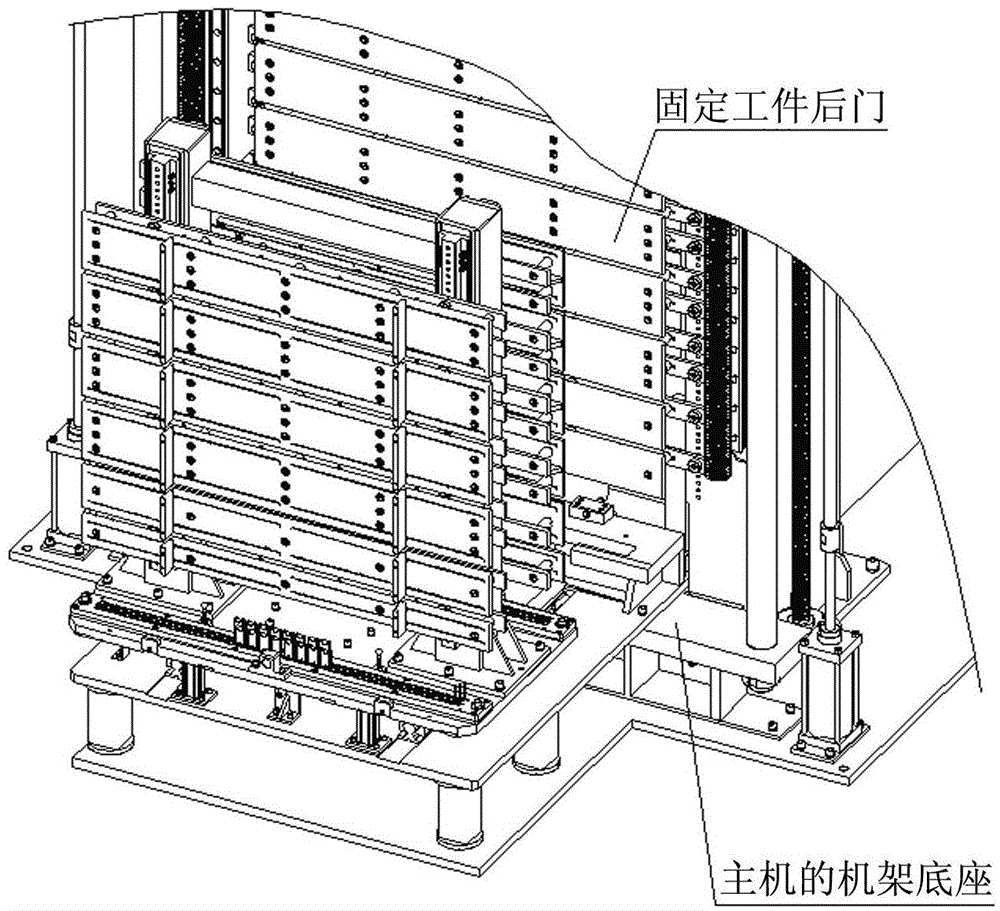

[0021] This design is effectively implemented, and its specific mode is exactly the same as the description made in the summary of the invention. Now in conjunction with the accompanying drawings, the present invention will be further described:

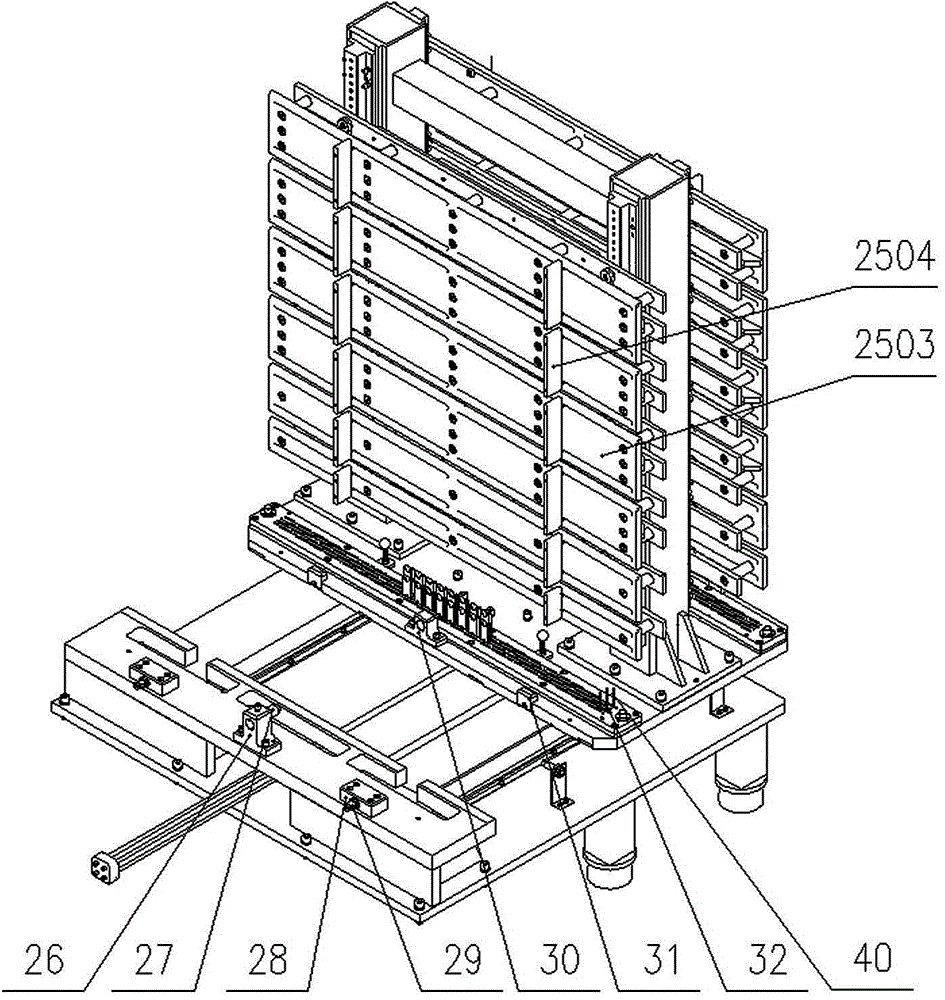

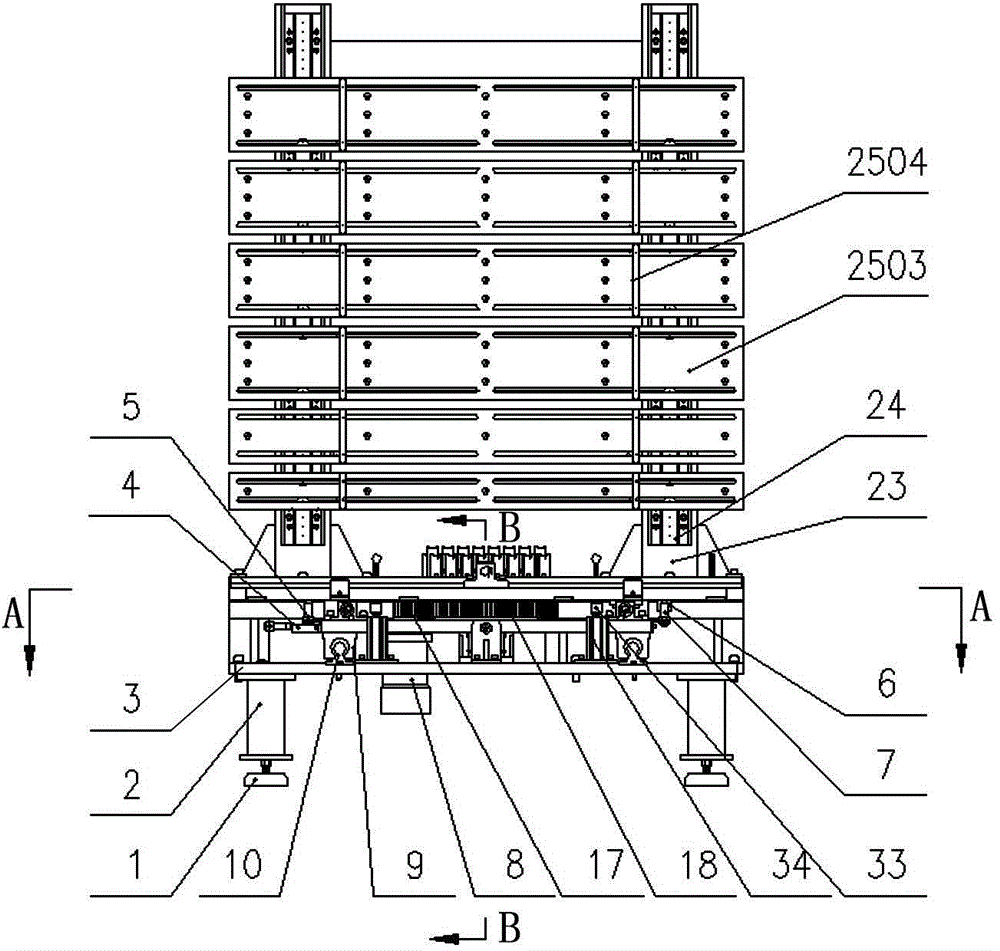

[0022] Step 1: Fixing the workpiece The front door assembly 25 has many different specifications, the specific difference lies in the heights of the front positioning plate 2503 and the side positioning strips 2504 are different. First, according to the height of the workpiece to be expanded, the number of rows of tubes to be expanded, the number of tubes in each row, the arrangement of the U-shaped tubes, etc., several groups of required fixed workpiece front door assemblies 25 are selected for combination, and then installed on the rotary The door workbench hangs on the mounting plate 24 of the door A face and the revolving door workbench hangs the door A face.

[0023] Step 2: Push the rotary table 22 to rotate, so that the side A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com