Lifting mechanism for feeding in vertical direction

A lifting mechanism, vertical technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of low control accuracy, difficult adjustment of height position, inability to meet high speed, high precision adjustment, etc., and achieve the effect of precise control and precise adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

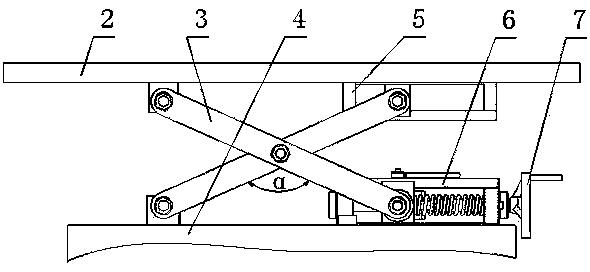

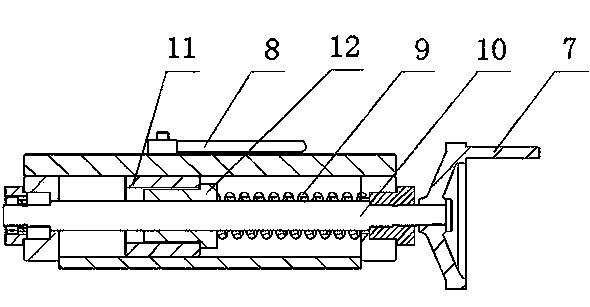

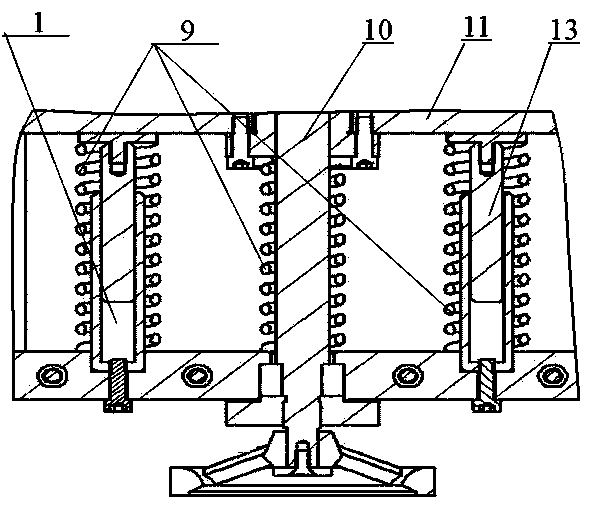

[0011] As shown in the figure, the present invention includes an upper workbench 2, a main slide mechanism 8, an auxiliary slide mechanism 5, an X-shaped bracket folding ladder 3, a lower workbench 4, and a main slide mechanism 6, which includes a handwheel 7, a wire Bar 10, leading screw nut 12, main slider 11, hand wheel 7 are arranged on one end of leading screw 10, main slider 11 links to each other with leading screw through leading screw nut 12. The present invention also includes a spring auxiliary support mechanism 1, the spring auxiliary support mechanism 1 includes a spring 9 arranged on the lead screw 10 between the lead screw nut 12 and the hand wheel 7, a combination of springs 9 arranged on both sides of the lead screw 10 Guide post 13, the combined guide post 13 is connected to the main slider 11 away from one end of the hand wheel 7; the combined guide post 13 arranged in parallel with the leading screw 10 plays a guiding role when the main slider 11 moves. A l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com