Automatically tested decoding board and test method thereof

An automated testing and decoding board technology, applied in electronic circuit testing, the layout of structural components in carrier equipment, etc., can solve problems such as the inability to standardize detection of DVD decoding boards, and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

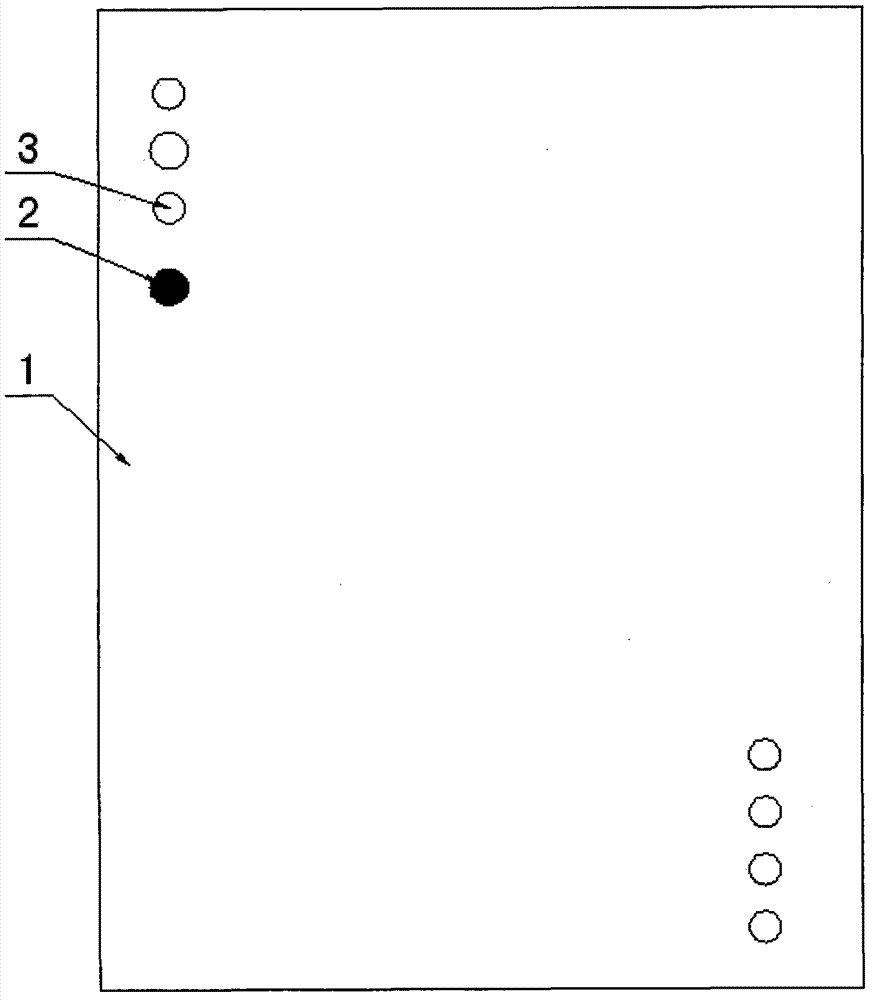

[0012] Such as figure 1 As shown, a kind of automated test decoding board of the present invention includes a PCB board 1 as a carrier, a printed circuit is arranged on the front side of the PCB board 1, and electrical components for execution are also installed on the PCB board 1, and the PCB board 1 The reverse side of the board 1 is provided with more than one via hole 3, the copper foil 2 is welded in the via hole 3, and the copper foil 2 protrudes from the PCB board 1, which is convenient for detection, and the PCB board 1 around the copper foil is Also marked with silk screen.

[0013] In a preferred mode of the present invention, the via hole is facing the printed circuit on the front side of the PCB 1 .

[0014] In a preferred manner of the present invention, the copper foil is connected to the printed circuit on the front surface of the PCB 1 .

[0015] In a preferred manner of the present invention, the copper foil 2 on the one via hole 3 is a test point.

[0016]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap