Anti-overheating capacitor

A capacitor and anti-overheating technology, applied in the field of capacitors, can solve problems such as unreliable connection, unreliable contact, virtual welding, etc., and achieve the effect of realizing overheating protection, solving overheating problems, and good implementation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The content of the present invention will be described below in conjunction with specific embodiments.

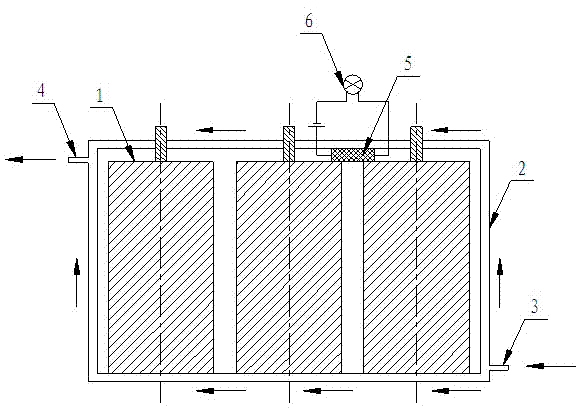

[0012] The anti-overheating capacitor of the present invention includes: a plurality of capacitors 1 and a metal shell 2 of the capacitors, and the capacitors 1 are all placed in the metal shell 2 . The metal shell 2 is hollow inside.

[0013] After any capacitor 1 is overheated, the internal temperature of the metal shell 2 will rise sharply, which will affect the service life of the capacitor and bring great safety hazards. In order to prevent the capacitor from overheating, a water inlet 3 and a water outlet 4 are provided on the hollow metal case 2 , and the water inlet 3 is at the bottom of the metal case 2 , and the water outlet 4 is at the top of the metal case 2 . The heat-conducting medium, such as water, enters the metal shell 2 through the water inlet 3 and finally flows out through the water outlet 4 .

[0014] Since the water outlet 4 is higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com