Motor temperature measurement and overtemperature protection method of drum washing machine

A drum washing machine, motor temperature technology, applied in the direction of thermometers using electric/magnetic elements that are directly sensitive to heat, automatic disconnection emergency protection devices, thermometers, etc., can solve the problems of increasing costs and affecting motor reliability, etc., to achieve Low cost, simple structure, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

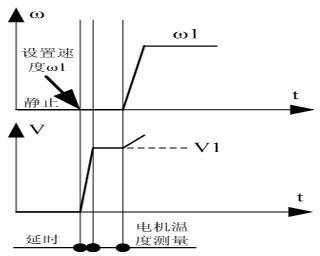

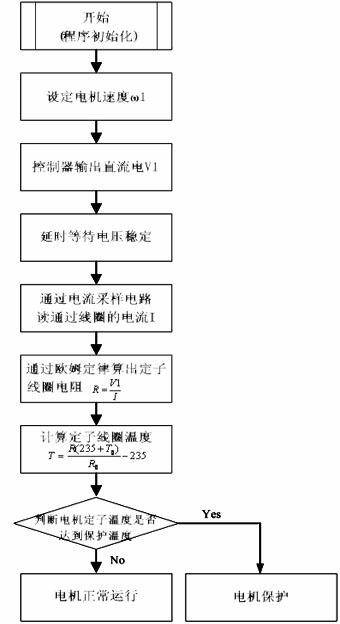

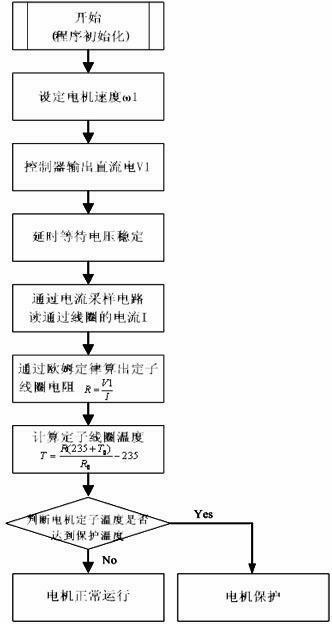

[0016] Such as figure 1 , with the output speed of the main controller Correspondingly, the drive controller outputs a DC voltage V1 for temperature measurement, and delays for a period of time to allow the voltage to stabilize before performing measurement calculations.

[0017] Such as figure 2 specific process. When the washing machine motor is not running, it is in the standby state, and the temperature monitoring and protection of the motor are ready. At the same time as the whole process starts, the main controller first receives the user's instruction: run the motor, and the received motor speed is , to instruct the motor controller to first output DC voltage V1. The DC voltage here is determined according to the current and the resistance of the motor coil. The requirement is that the current I used to participate in the calculation is 1.4~1.8A. , the output DC voltage V1 is 5~7V.

[0018] Delay 80~100ms, wait for the voltage to stabilize, and then obtain the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com