Injection molding equipment for buttons

A technology of injection molding and equipment, which is applied in the direction of household components, household appliances, and other household appliances, etc., can solve the problems that affect the normal production and operation of button production enterprises, harsh process conditions, and high button production costs, so as to achieve smooth molding, The effect of improving quality and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

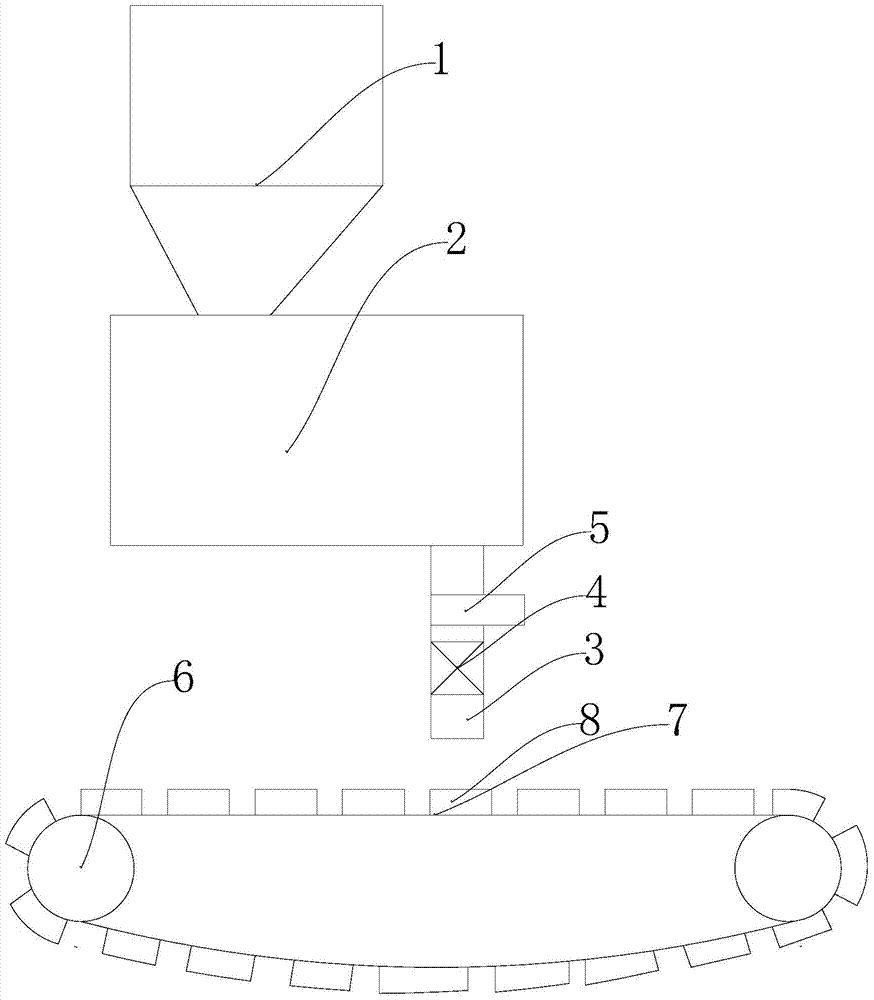

[0011] Such as figure 1 As shown, the button injection molding equipment described in this embodiment includes a hopper 1, a heater 2 is connected below the hopper 1, a discharge pipe 3 is provided at the bottom of the heater 2, and a discharge pipe 3 is provided below the discharge pipe 3. Two rotating sprockets 6 are arranged at the same horizontal position of the rotating sprocket 6, and a chain 7 is wound around the rotating sprocket 6, and forming molds 8 are arranged at intervals on the chain 7, and a solenoid valve 4 is arranged at the outlet of the discharge pipe 3, The discharge pipe 3 at the upper end of the electromagnetic valve 4 is provided with a flow meter 5, the rotation speed and the steering direction of the two rotating sprockets 6 are the same, and the chain 7 on the upper side of the rotating sprocket 6 is in a tight state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com