Turning belt side-pulling track mechanism

A belt and track technology, applied in the field of turning belt side pull track mechanism, can solve the problems of inability to perform high-speed rotation, transported items deviating from the track, rotating centripetal force decomposition, etc., to solve the problem of belt deviation, easy to use, and easy to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

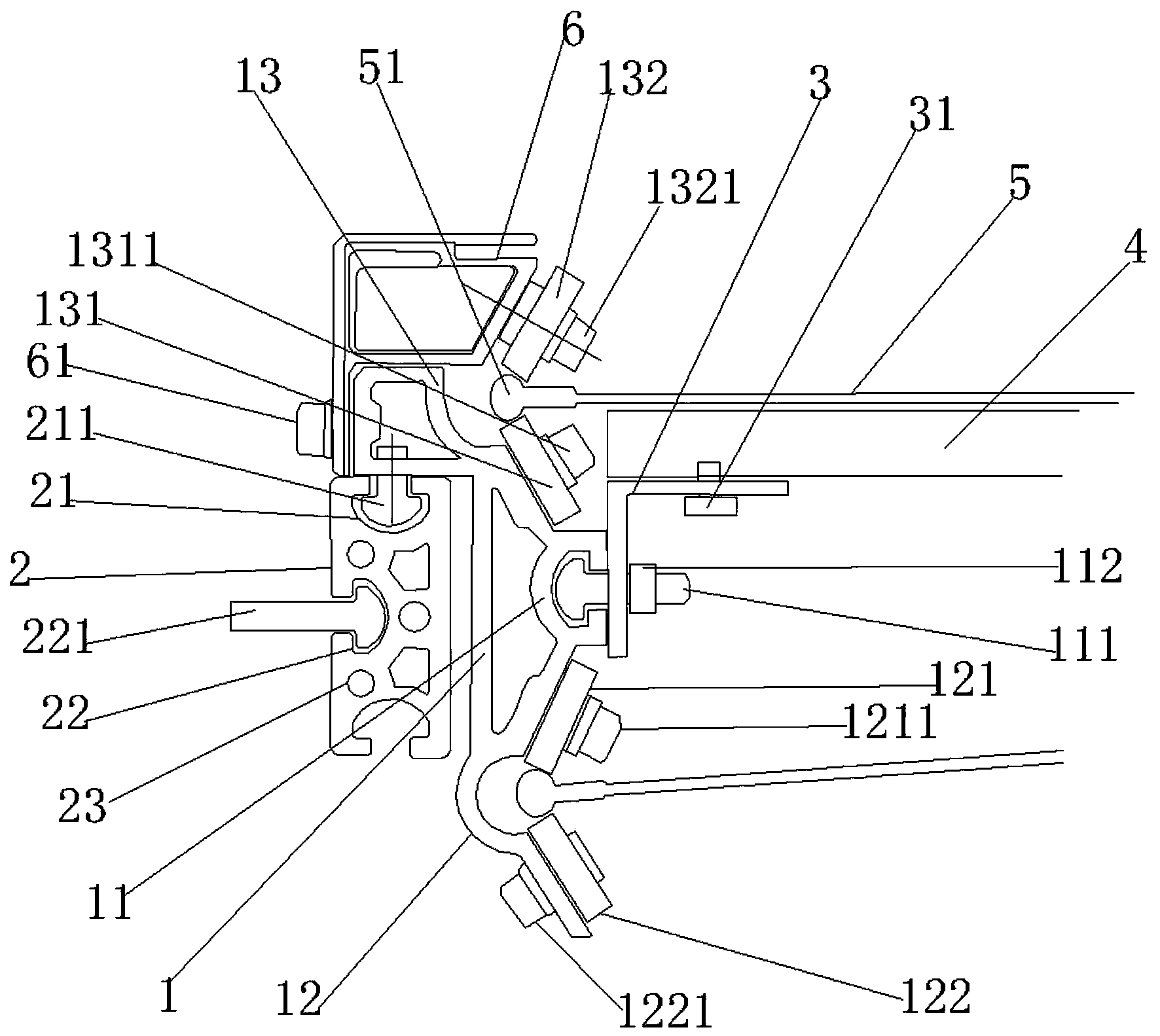

[0018] Such as figure 1As shown, a turning belt side pull track mechanism includes a triangular support block 1, and the right side of the triangular support block 1 is provided with an inner bolt fixing groove 11, and the inner bolt fixing groove 11 is provided with an inner bolt 111. The inner bolt 111 is provided with an inner bolt lock nut 112, the lower side of the triangular support block 1 is fixedly provided with a lower track groove 12, the upper side of the triangular support block 1 is fixedly provided with an upper track groove 13, and the lower side of the triangular support block 1 is fixedly provided with an upper track groove 13, and the lower side of the triangular support block 1 The side is provided with an installation connection block 2, and the right side of the triangular support block 1 is provided with a belt plate support frame 3, and the belt plate support frame 3 is fixed on the triangular support block 1 by inner bolts 111, and on the belt plate sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com