Air intake for internal combustion engines

An air intake device, internal combustion engine technology, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve problems such as crankshaft noise, and achieve the effect of optimizing combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

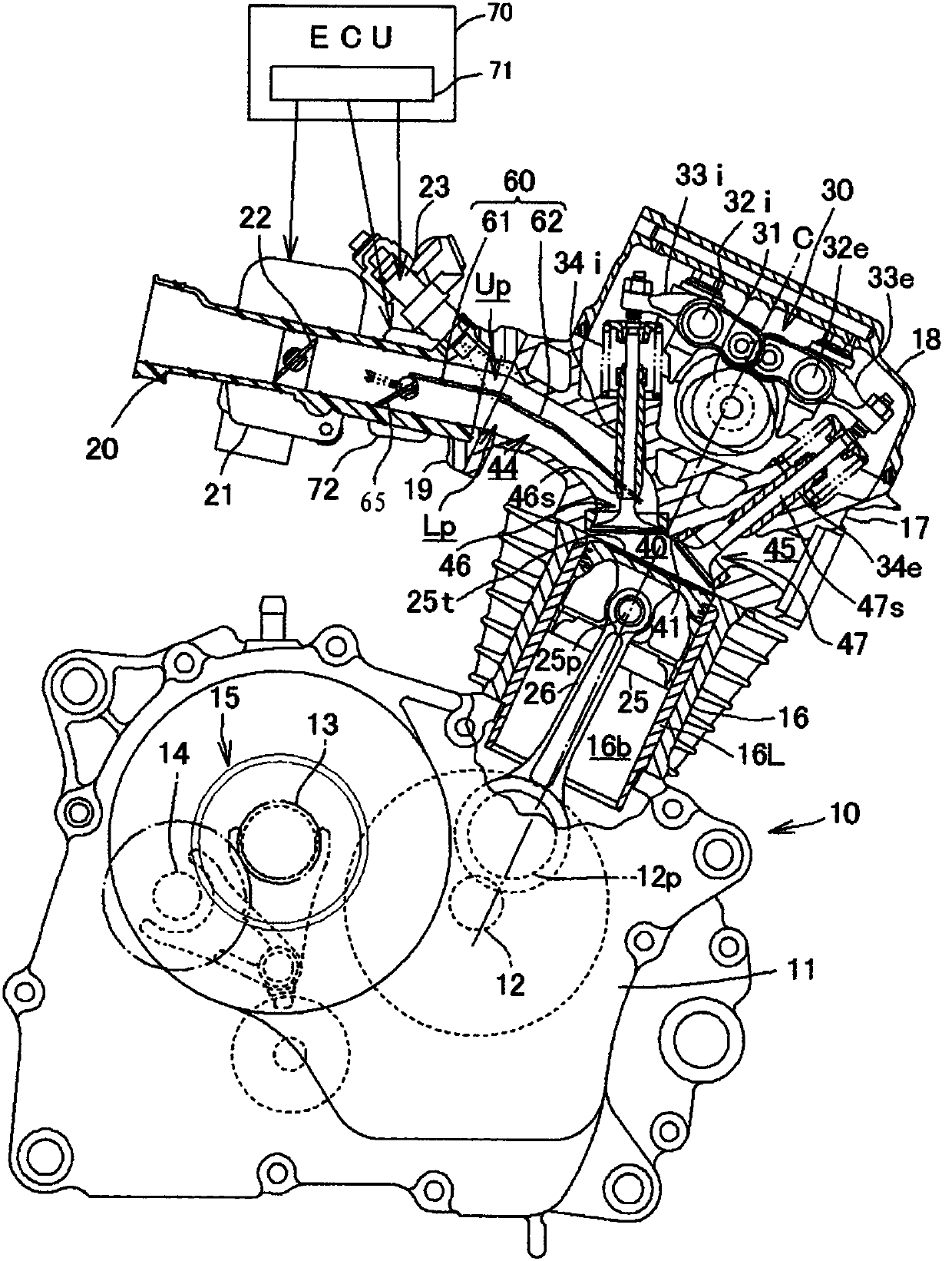

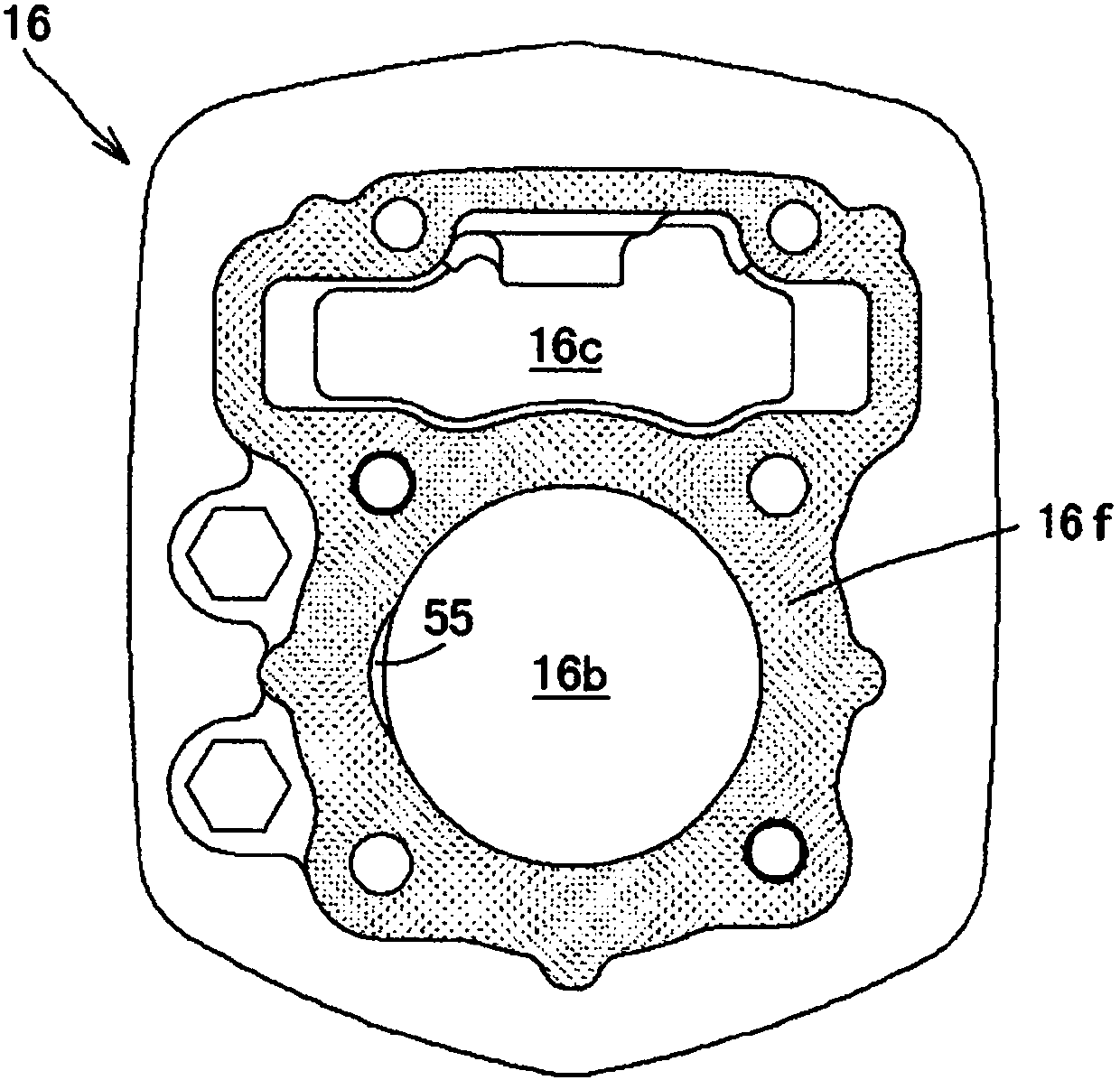

[0049] Below, based on Figure 1 to Figure 13 An embodiment of the present invention will be described.

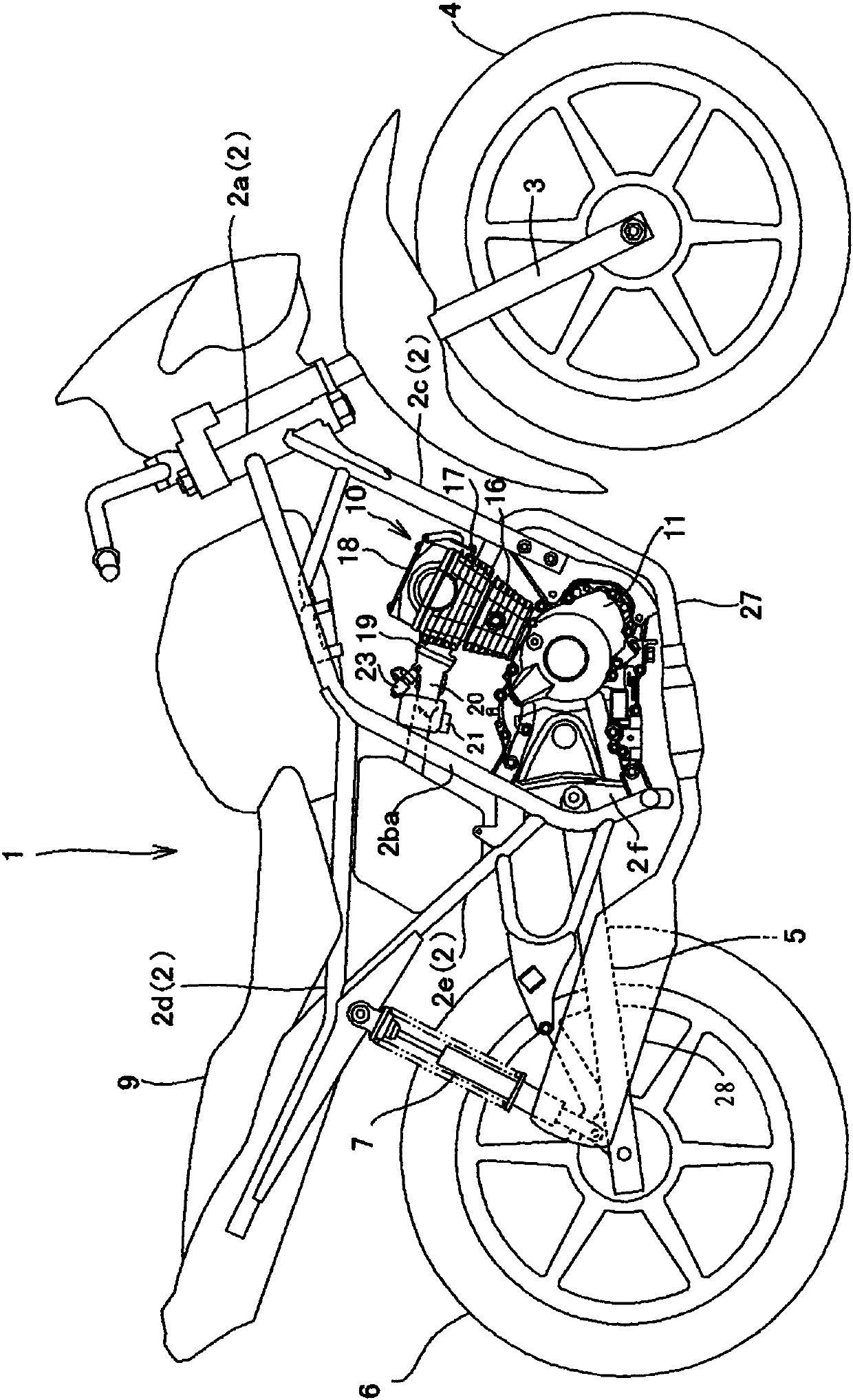

[0050] figure 1 It is an overall side view of the two-wheeled motor vehicle 1 equipped with the internal combustion engine 10 of this embodiment.

[0051] The frame 2 of the two-wheeled motor vehicle 1 has a pair of left and right main frames 2b, 2b extending rearward from the head pipe 2a and then bending downward to form steeply inclined portions 2ba, 2ba. The lower part of the frame 2 is bent forward to the lower end in a U shape.

[0052] In addition, the pair of left and right descending frames 2c and 2c are inclined downward from the head pipe 2a at a steep angle, and are directed substantially parallel to the steeply inclined portion 2ba of the main frame 2b in a side view.

[0053] The seat rails 2d, 2d extend rearward from the upper part of the steeply inclined portions 2ba, 2ba of the main frame 2b, 2b, and a rear tie rod 2e connected to the central portion of the seat r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com