Extracting pot with homogenization baffle plate

An extraction tank and homogenization technology, which is applied in the field of pharmaceutical equipment, can solve the problems of mixing and contacting medicinal materials, inability to quickly extract the active ingredients of medicinal materials, and reducing the extraction efficiency of the extraction tank, so as to improve the content of active ingredients, mix fully, and improve extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

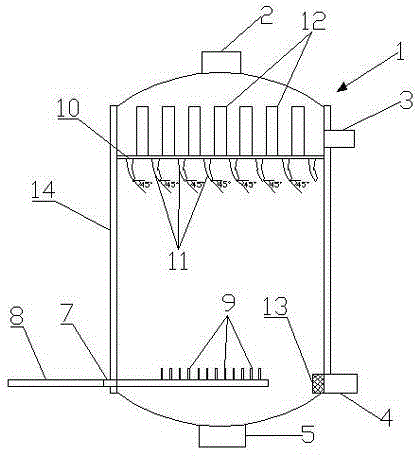

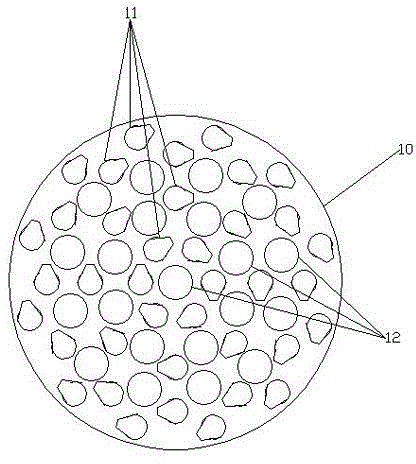

[0036] The extraction tank with the homogenization partition of the present invention is as figure 1 As shown, the tank body 1 is included, and the shape of the tank body 1 can be selected according to needs. In this embodiment, the tank body 1 is cylindrical. The upper part of the tank 1 is provided with a feed port 3, the top is provided with an air outlet 2, the bottom is provided with a slag outlet 5, and the lower part is provided with a liquid outlet 4 and an air inlet 7 (it can also be arranged at the bottom of the tank 1 ). The outer wall of the tank body 1 is provided with a heating interlayer 14, and the heating interlayer 14 can heat the tank body 1 through a built-in heating wire or passing steam into it. In this embodiment, the heating interlayer 14 is provided with There is a heating wire (not marked in the accompanying drawings); a vent pipe 8, the vent pipe 8 extends into the tank body 1 through the air inlet 7, and the connection between the vent pipe 8 and t...

Embodiment 2

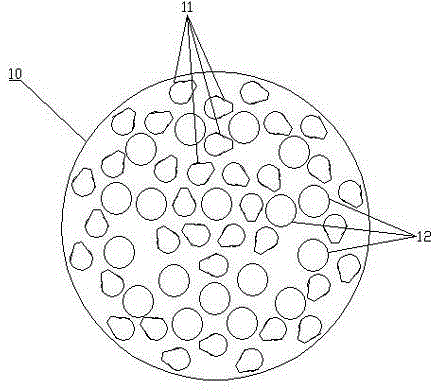

[0041] On the basis of the above examples, if image 3 As shown, the spray pipes 11 on the separator 10 in this embodiment are arranged along multiple circumferences, but these multiple circumferences are not concentric. After the liquid passes through the separator 10, a state where the liquid vortex and turbulent flow coexist, the liquid and medicinal materials can still be well mixed and contacted.

Embodiment 3

[0043] On the basis of the above examples, if Figure 4 As shown, the extraction tank described in this embodiment also includes a circulation pump 6, the circulation pump 6 is provided with a pump inlet and a pump outlet, the pump inlet is connected to the liquid outlet 4, and the pump outlet It is connected with feed port 3. The pipeline connecting the circulation pump 6 and the tank 1 is not provided with a pressure relief valve or a switch. Since the liquid vortex formed under the partition 10 can significantly improve the extraction efficiency of the active ingredients of the medicinal material by the solvent, the liquid vortex and the medicinal material are briefly mixed. Immediately after contact, the circulation pump 6 can be drawn back to the feed inlet 3 for recirculation, and the circulation pump 6 can increase the speed of the liquid medicine at the feed inlet 3, so that the liquid can convert part of its kinetic energy into a vortex after passing through the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com