A high-pressure reheating gas-steam combined cycle power generation system and power generation method

A power generation system and high-pressure technology, which is applied in the field of high-pressure reheat gas-steam combined cycle power generation system, can solve the problems of high cost and high technical requirements of gas turbine equipment, and achieve the effect of reducing the difficulty of starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

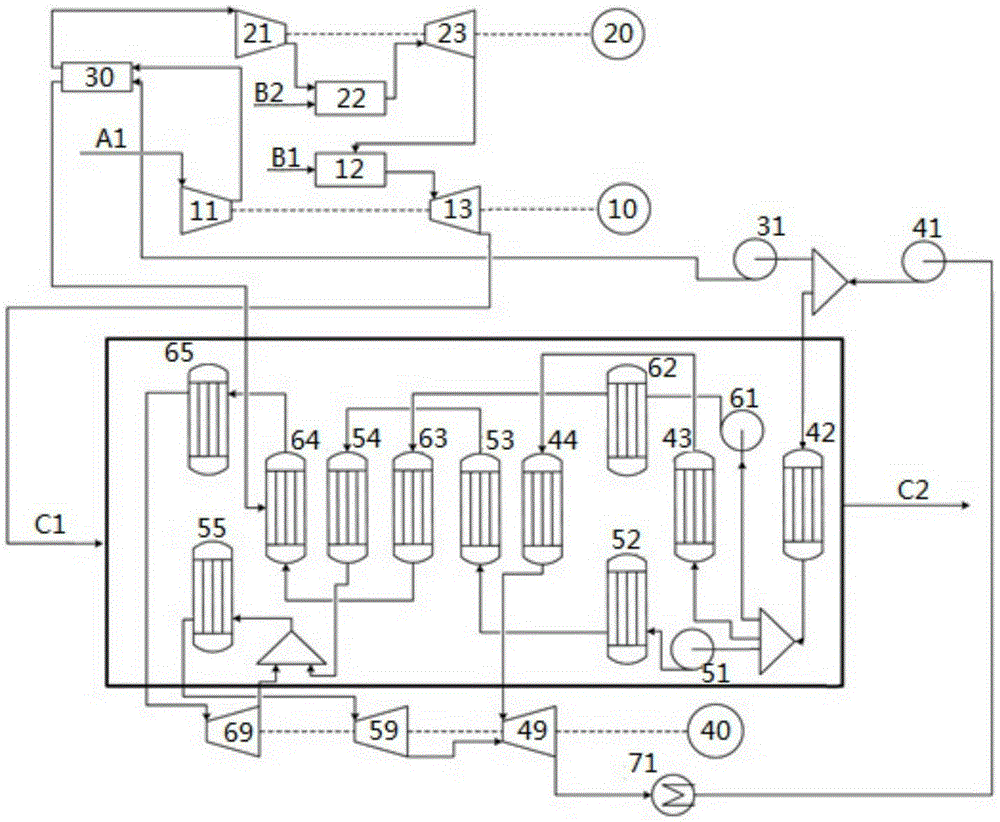

[0064] The power generation system structure of this embodiment is as follows figure 1 shown.

[0065] In the gas turbine subsystem, the medium pressure gas turbine 13 is coaxial with the primary compressor 11, the high pressure gas turbine 23 is coaxial with the secondary compressor 21, and the gas turbine is connected to the generators 10 and 20; the high pressure system and the medium The pressure system adopts split shaft arrangement;

[0066] In the steam turbine subsystem, a triple-pressure reheating waste heat boiler and a steam turbine are set. The specific structure is: the water supply structure is divided into high, medium and low pressure water lines, and the steam turbine is provided with a high pressure cylinder 69, a medium pressure cylinder 59 and a low pressure cylinder 49. Condenser 71 is connected to low-pressure water pump 41. After pressurization, it is divided into two routes. One route is connected to cold water pump 31, intercooler 30, high-pressure ...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is that the high, medium and low cylinder intake air intake temperatures in the steam generation sub-system are respectively set to 540°C, 540°C and 305°C; the rest of the structure and parameters are the same as those in embodiment 1 Basically stay the same.

Embodiment 3

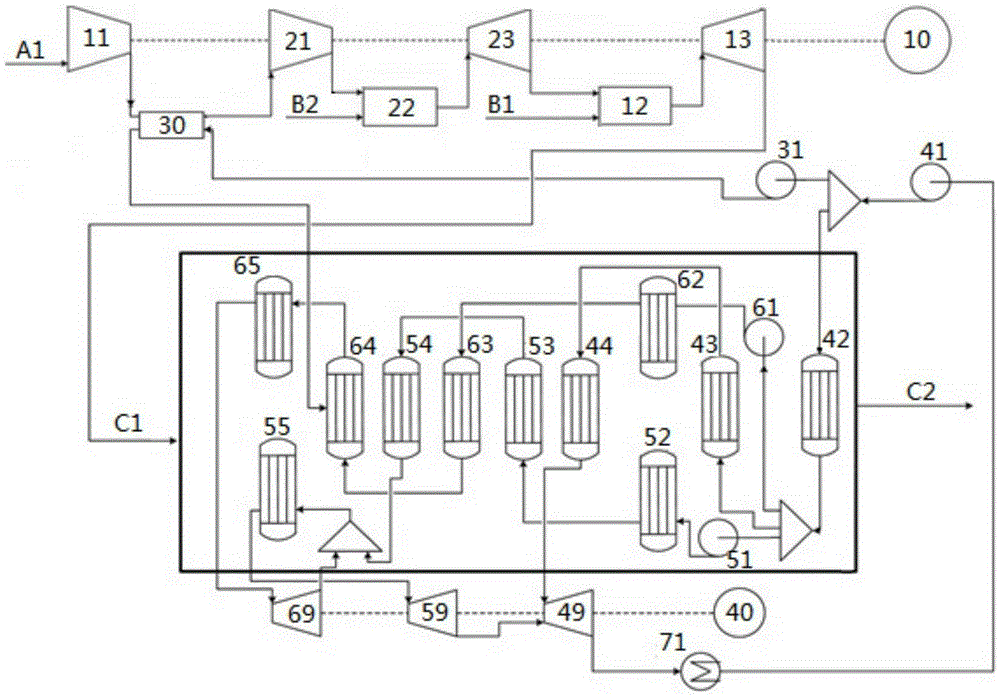

[0072] The power generation system structure of this embodiment is as follows figure 2 shown. The difference between this embodiment and Embodiment 1 is that the high-voltage system and the medium-voltage system adopt a coaxial arrangement; other structures and parameters are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com