A rapid start-up method for continuous flow improved UCT autotrophic nitrogen and phosphorus removal process based on anaerobic ammonium oxidation

An anammox and autotrophic denitrification technology is applied in the field of rapid start-up of the continuous flow improvement UCT autotrophic nitrogen and phosphorus removal process based on anammox, which can solve the problems of long start-up time of the Anammox process and achieve bacterial It has the effect of high efficiency of separate cultivation, shortening of startup time, and reduction of heating power costs and pharmaceutical costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

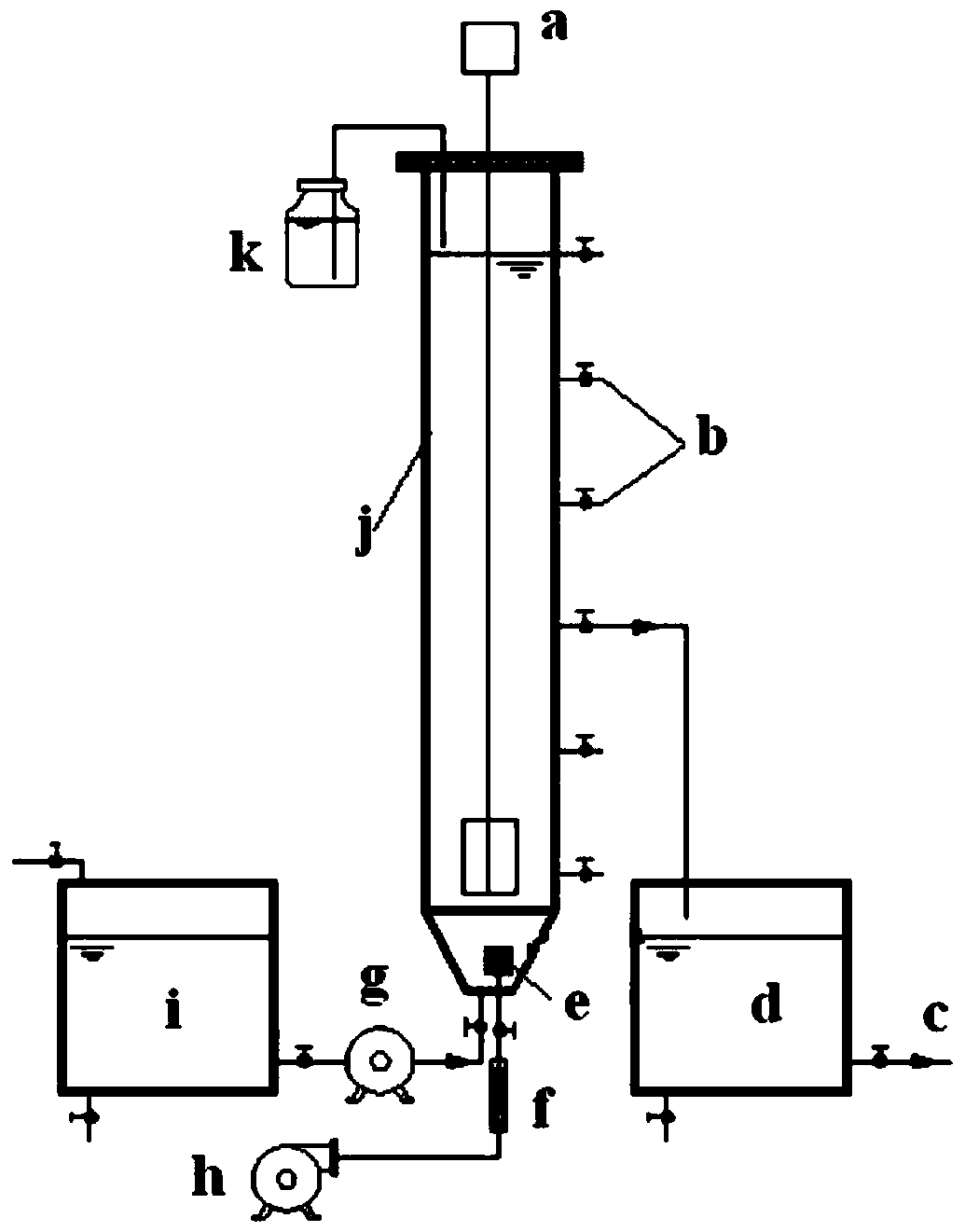

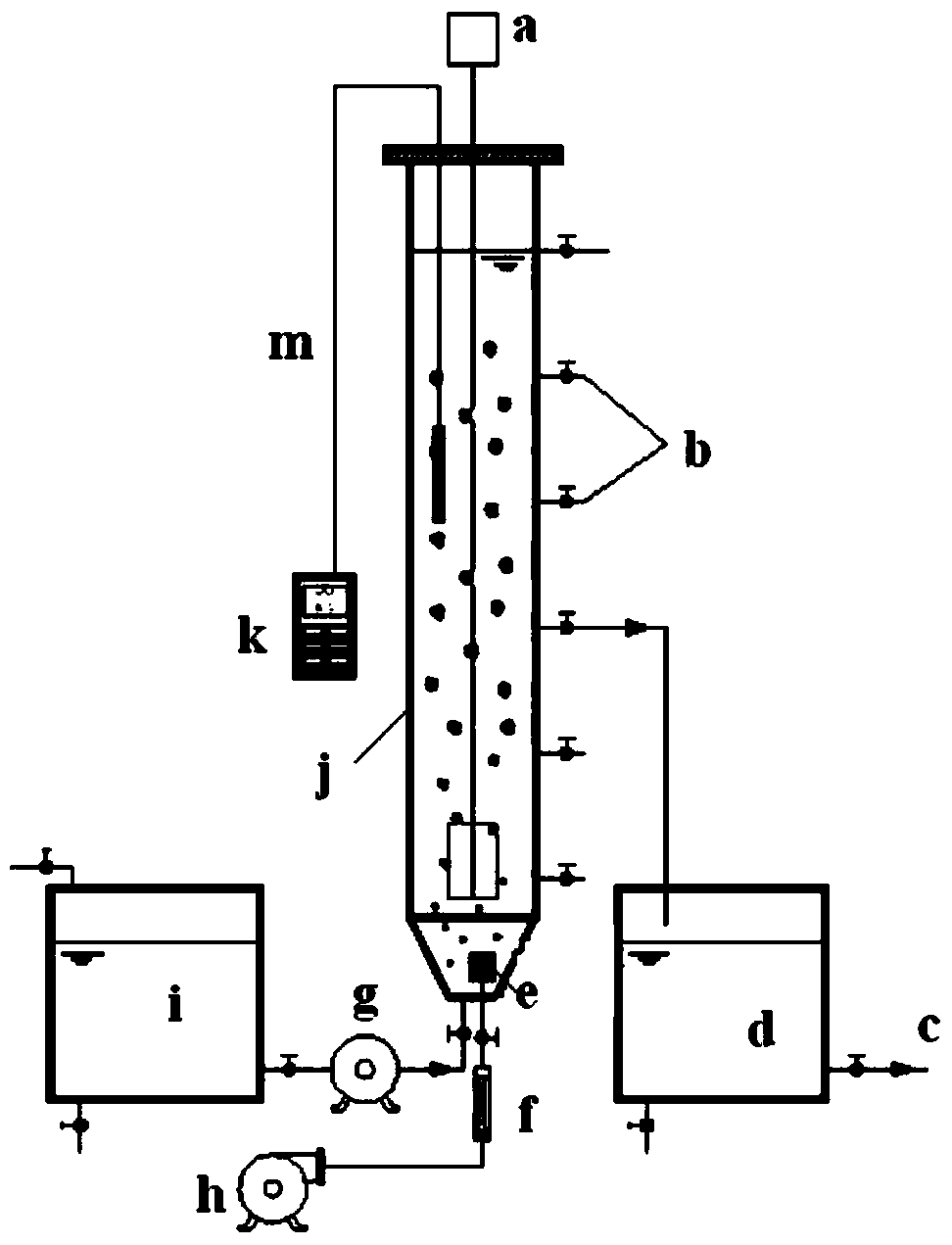

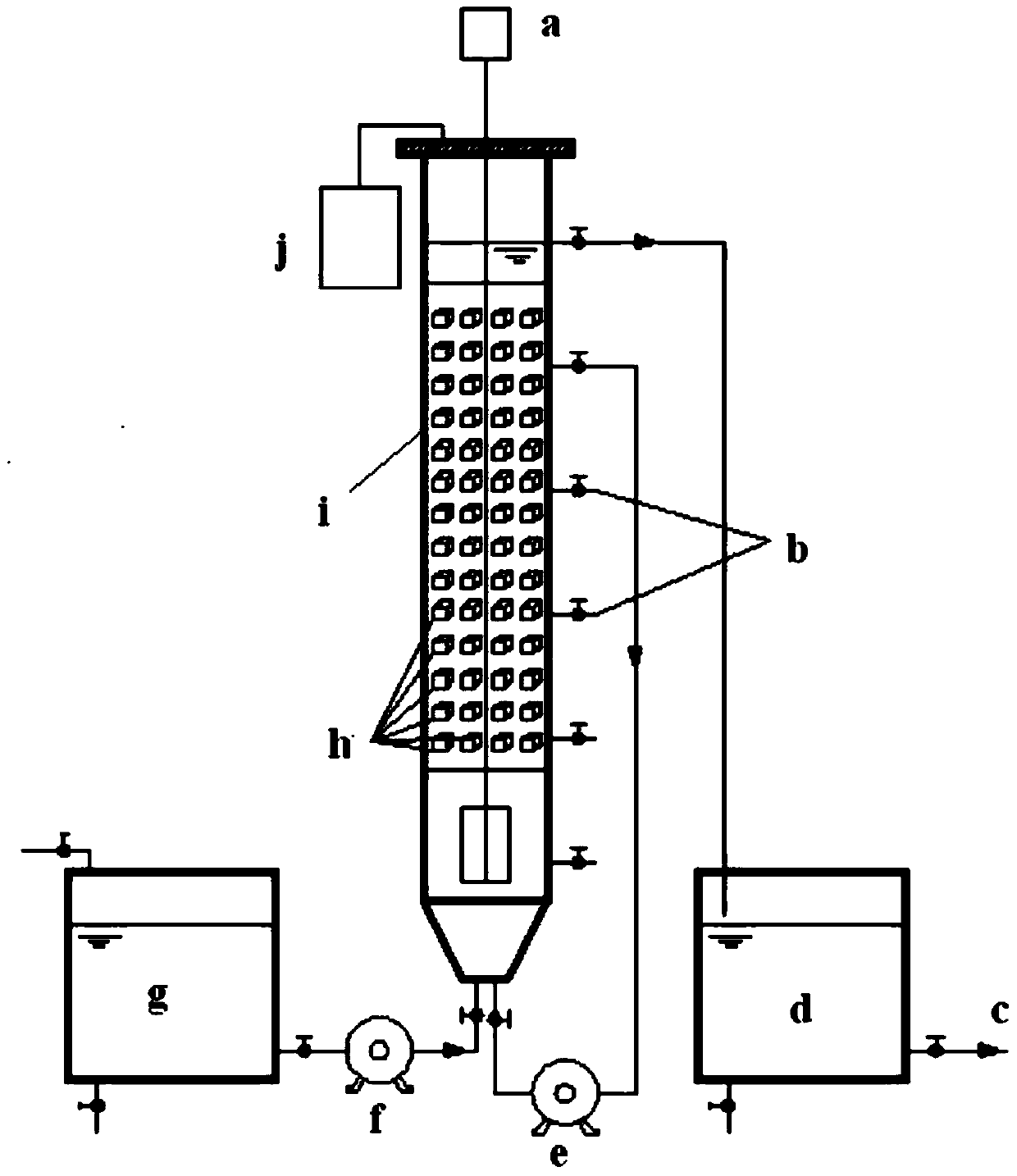

[0024] Specific embodiment 1: This embodiment is a continuous flow modified UCT autotrophic nitrogen and phosphorus removal process based on anaerobic ammonium oxidation. The method is carried out according to the following steps:

[0025] 1. Build the system:

[0026] Two sets of denitrification phosphorus removal systems, two short-cut nitrification systems and two anaerobic ammonia oxidation systems were built; the denitrification phosphorus removal system and the short-cut nitrification system were in the form of sequence batch reactors; the anaerobic ammonia oxidation system was anaerobic Filter form;

[0027] 2. Inoculated sludge

[0028] The denitrification phosphorus removal system is inoculated with ordinary activated sludge with phosphorus removal ability, and the inoculated sludge concentration is 4000~5000mg / L; the short-cut nitrification sludge system is inoculated with nitrification performance of ordinary nitrified sludge, and the inoculation sludge concentration is 300...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment is different from Embodiment 1 in that the effective solvent of the denitrification phosphorus removal system and the short-range nitrification system is 10L, an aeration device is set at the bottom, and a stirring device is set at the top. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: This embodiment is different from specific embodiment one or two in that: the effective volume of the anaerobic ammonia oxidation system is 8L, the height-to-diameter ratio is 3.5, the upper part is equipped with a stirring device and a gas collection device, and a sponge packing frame is arranged inside , The sludge internal circulation pump is set outside. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com