A method for lubricating and cooling splines of a wind power gearbox

A wind power gearbox, lubrication and cooling technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of gluing, increasing temperature, neglecting spline lubrication and cooling, etc., to achieve a simple mechanical structure , the effect of normal temperature and low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

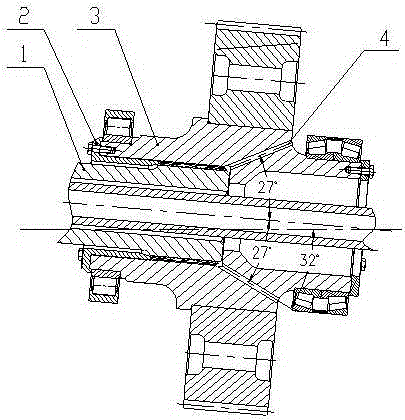

[0010] Referring to the accompanying drawings, in the wind power gearbox, the splines on the sun gear 1 are external splines, and the splines on the spline sleeve are internal splines. The sun gear and the spline sleeve are fitted together to make the splines mesh. The left side of the spline on the sun gear is axially positioned by the sun gear pressure plate 2, the right end of the sun gear pressure plate is an arc surface transition, and the sun gear pressure plate and the spline sleeve are connected together by bolts. After all components are fixed, a 10mm wide circumferential gap is formed between the sun gear and the sun gear pressure plate. On the spline sleeve on the right side of the inner and outer spline meshing parts of the sun gear and the spline sleeve, there are two holes 4 with an angle of 27° to the sun gear axis symmetrically with the sun gear axis, and the lubricating oil flows from the sun gear. The gap between the wheel and the sun gear pressure plate flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com