Hornet trapping device

A technology for trapping and wasps, applied in the field of bee breeding, can solve the problems of poor effect, labor and time-consuming, high labor intensity, etc., and achieve the effect of high efficiency, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

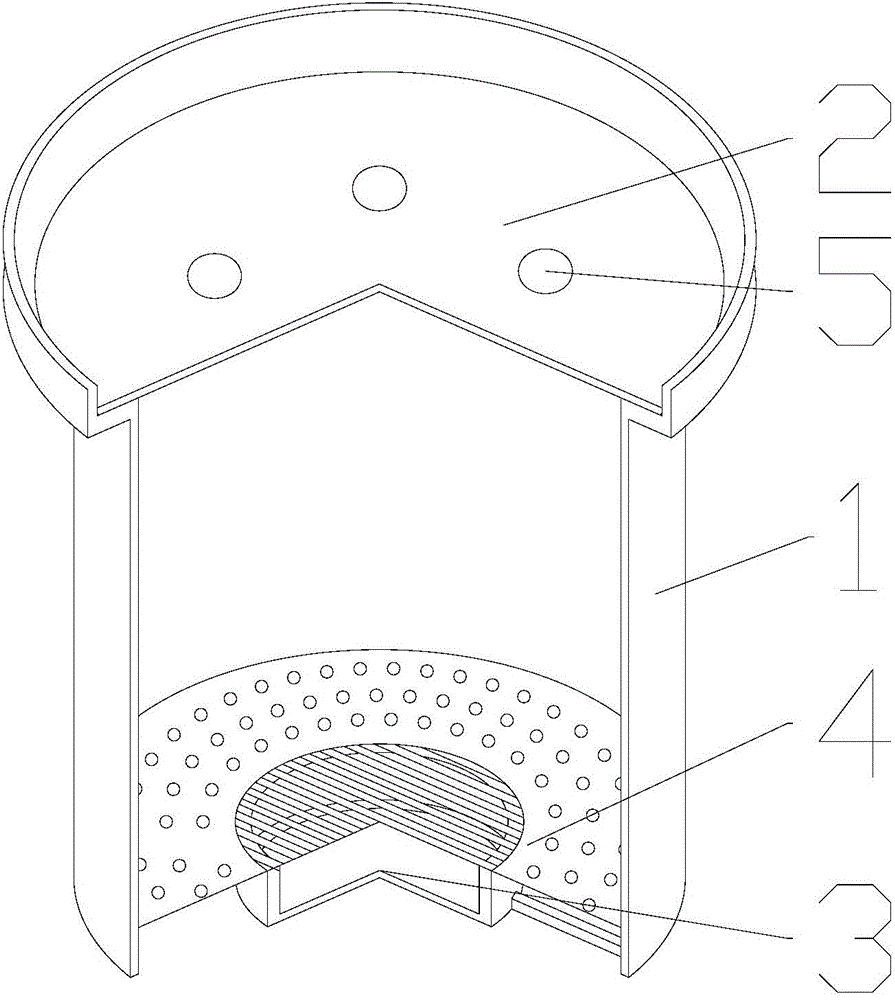

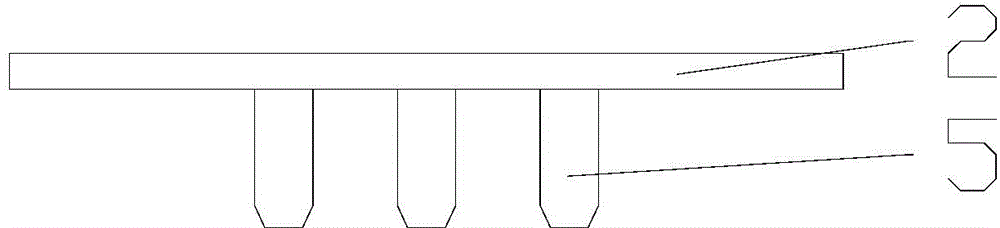

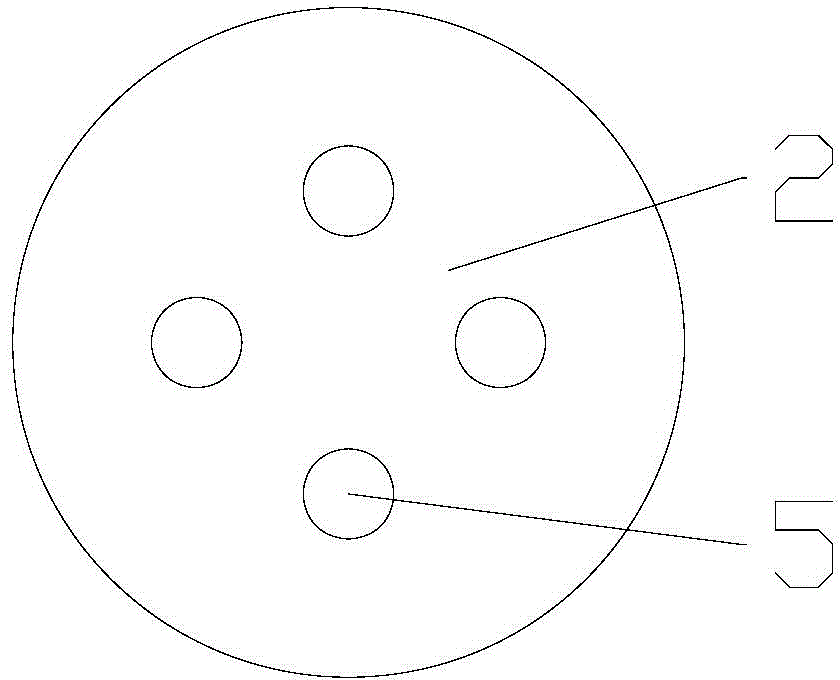

[0025] Figure 1-Figure 7 The wasp trapping device provided by the first embodiment of the present invention is shown, including a bee storage bucket 1, a bee inlet plate 2, a bait box 3, and a cover plate 4. The bee storage bucket 1 is provided with two open ends, and the bee inlet plate 2 is provided At one of the open ends of the honeycomb storage bucket 1, the honeycomb inlet plate 2 is provided with three honeycomb inlet channels 5, which extend into the honeycomb storage barrel 1, and the aperture of the end of the honeycomb channel 5 away from the honeycomb board 2 shrinks. The lowermost aperture is 8-12mm, the bait box 3 is set at the other open end of the bee storage bucket 1, the cover plate 4 is set above the bait box 3, the edge of the cover plate 4 is in contact with the bee storage bucket 1, and the cover plate 4 covers A part of the bait box 3 is provided with a vent hole, and the rest of the cover plate 4 is provided with a bee hole.

[0026] Hang the hornet trapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com