A cutting tool with adjustable leading angle

A cutting tool and leading angle technology, which is applied to lathe tools, turning equipment, hand-held tools, etc., can solve the problem that the leading angle cannot be continuously adjusted, the leading angle cannot be continuously adjusted, and the cost of cutting processing Increase and other issues, to achieve the effect of reducing auxiliary processing time, increasing the rate of repeated utilization, and facilitating processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiment and accompanying drawing, it should be pointed out that protection scope of the present invention is not only limited to following embodiment, for those of ordinary skill in the art, without departing from the principle premise of the present invention The following improvements and modifications should also be considered as protection scope of the present invention.

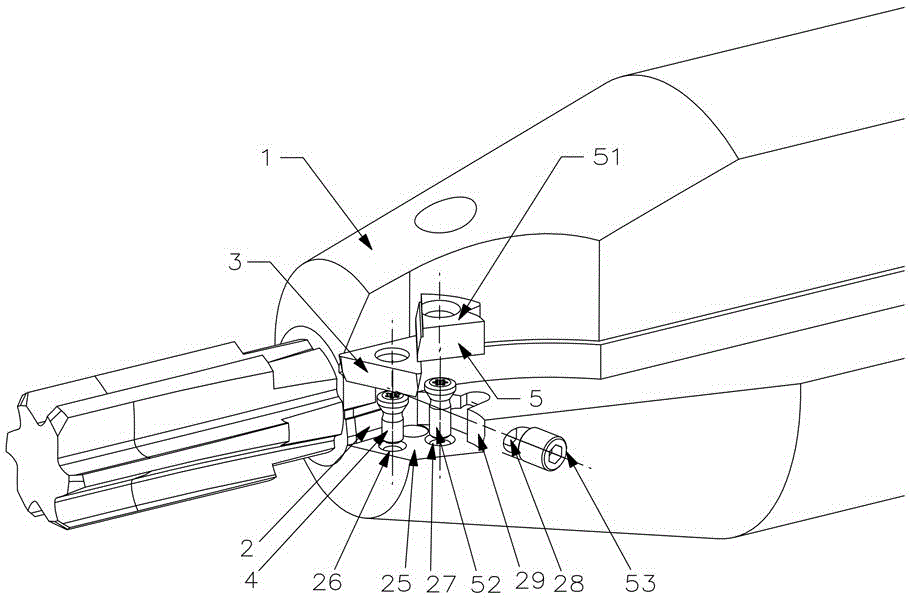

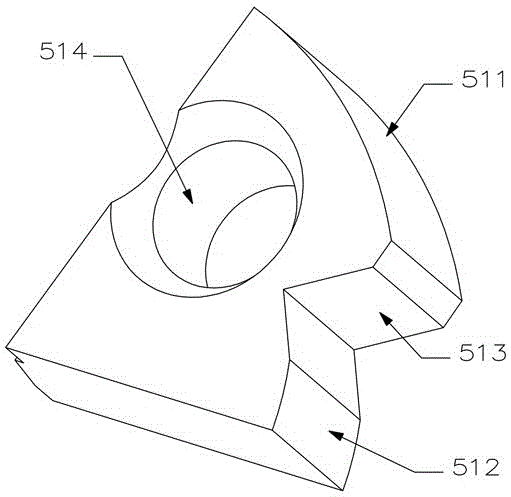

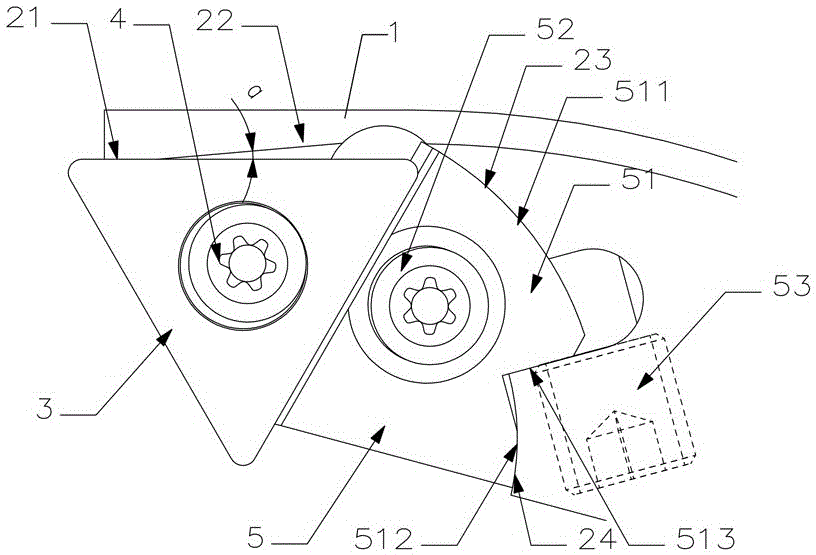

[0024] Figure 1 to Figure 4 An embodiment of the present invention is shown. The cutting tool with adjustable entering angle of this embodiment includes a tool body 1, a cutting blade 3 and an adjustment block 51. The tool body 1 is provided with a sipe 2, and the sipe 2 includes A sipe bottom 25 and a sipe side 29 . The bottom surface of the knife groove 25 is provided with a blade screw hole 26 and an adjustment block screw hole 27. The cutting blade 3 is pressed on the bottom surface of the knife g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com