Suspension system for electric vehicle power assembly

A powertrain and suspension system technology, applied in power plants, vehicle parts, jet propulsion devices, etc., can solve problems such as high cost, large rubber mount volume, and poor vibration isolation effect, and achieve vibration isolation capability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

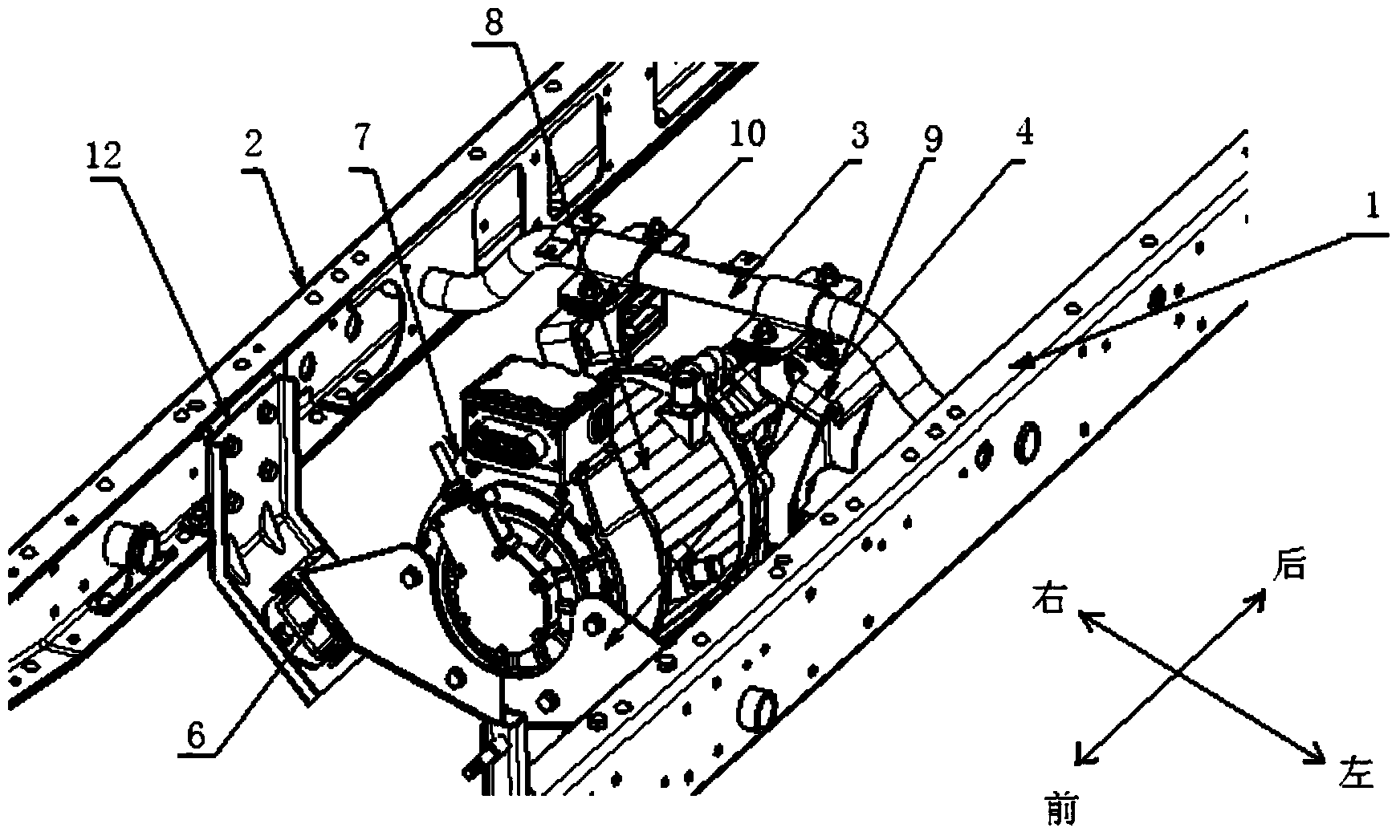

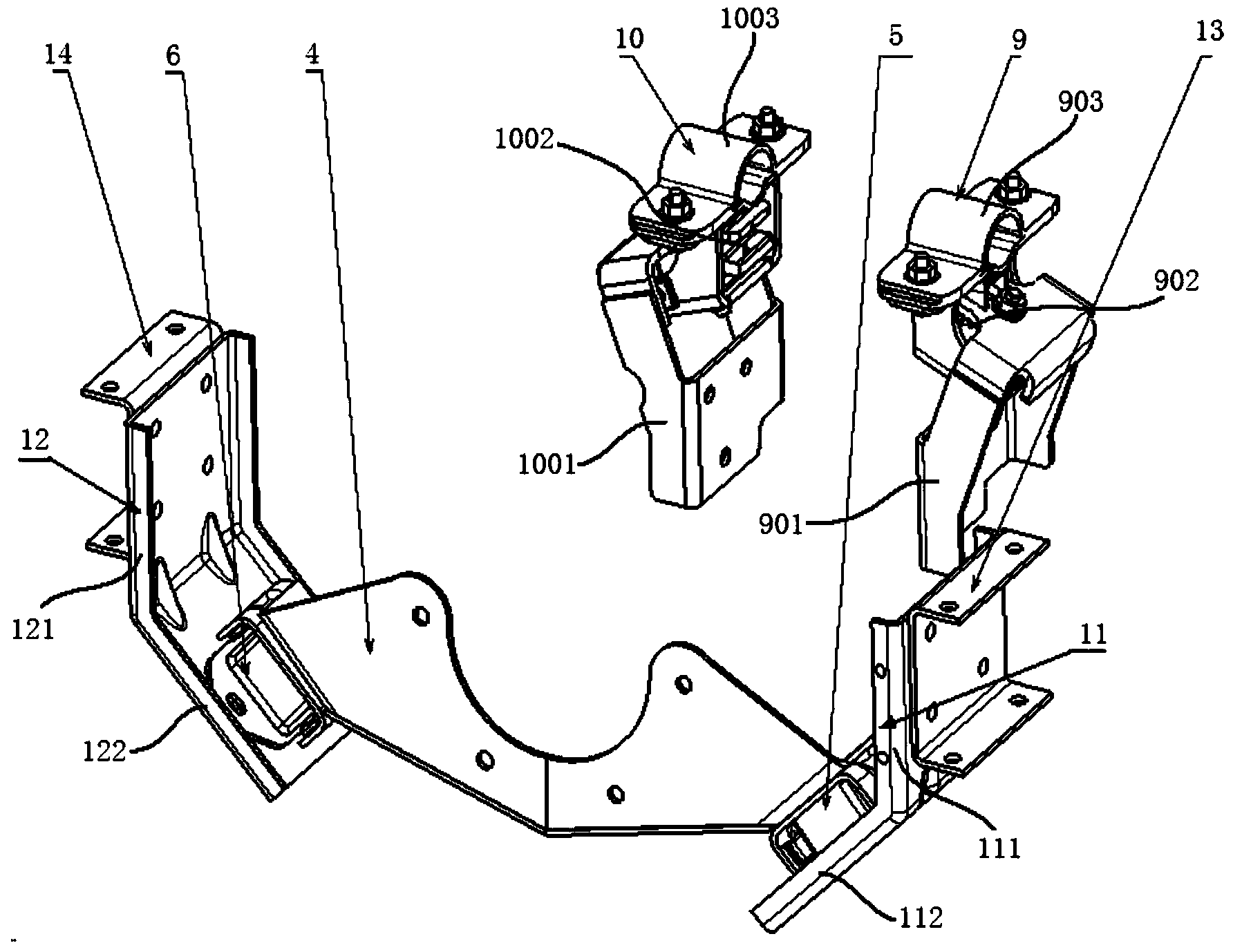

[0019] In the following description in conjunction with the accompanying drawings, the left-right direction refers to the vehicle width direction, or lateral direction; the front-rear direction refers to the vehicle length direction, or longitudinal direction.

[0020] refer to figure 1 , in the development of electric vehicles, it is a more economical and quicker choice to use the frame of a traditional fuel engine vehicle. Overall it's too big. Of course, the embodiment of the present invention is not limited to the electric vehicle powertrain consisting of the electric motor 7 and the speed reducer 8 only. In this embodiment, both ends of the beam 3 are rigidly connected to the left longitudinal beam 1 and the right longitudinal beam 3 respectively, the plate-shaped bracket 4 and the beam 3 are arranged at intervals in the longitudinal direction, and the two ends of the plate-shaped bracket 4 are suspended by the left Set the cushion 5 ( figure 2 shown in) and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com