Heavy-load hydraulic lifting device

A lifting device, hydraulic technology, used in the direction of tilting load-bearing vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

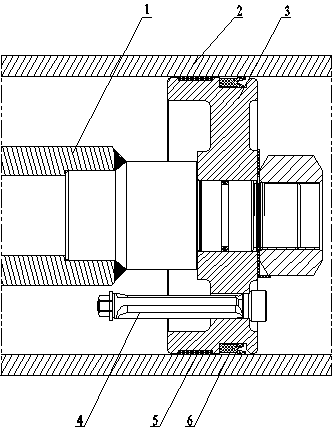

[0016] like figure 1 Shown is the preferred embodiment of the heavy-duty hydraulic lifting device of the present invention.

[0017] The heavy-duty hydraulic lifting device includes a push rod 1, a cylinder 2 and a piston 3, and also includes a limit rod 4, which is fixedly connected with the piston 3, and moves along with the piston 3 along the Cylinder 2 slides axially.

[0018] In this embodiment, the heavy-duty hydraulic lifting device further includes a guide belt 5 installed between the cylinder 2 and the piston 3 .

[0019] In this embodiment, the heavy-duty hydraulic lifting device further includes a sealing ring 6, which is installed between the cylinder 2 and the piston 3, and the cross section of the sealing ring 6 is "Y". "type.

[0020] Apparently, the above-mentioned embodiments are only examples for clear description, rather than limiting the implementation. For those of ordinary skill in the art, other changes or changes in different forms can be made on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com