A miniaturized gas generator

A gas generator and shell technology, applied in the field of miniaturized gas generators, can solve the problems of miniaturization and cost reduction without using the generator, low space utilization rate, and high output slope of the generator, so as to improve reliability and environmental adaptability, avoiding heat loss or ignition delay, and improving utilization and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

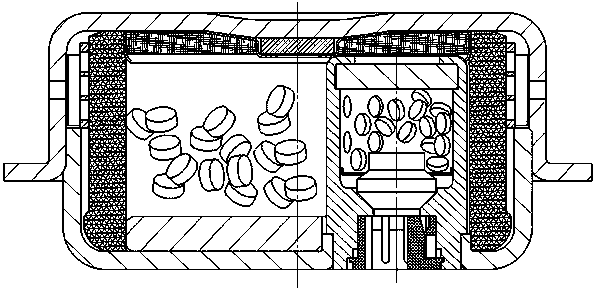

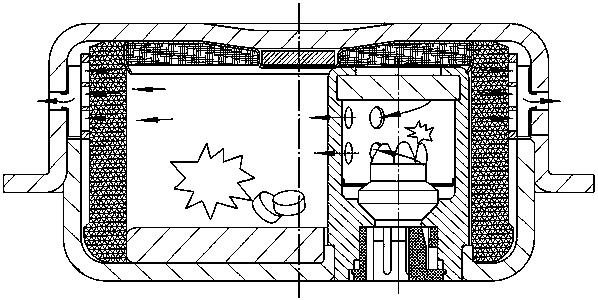

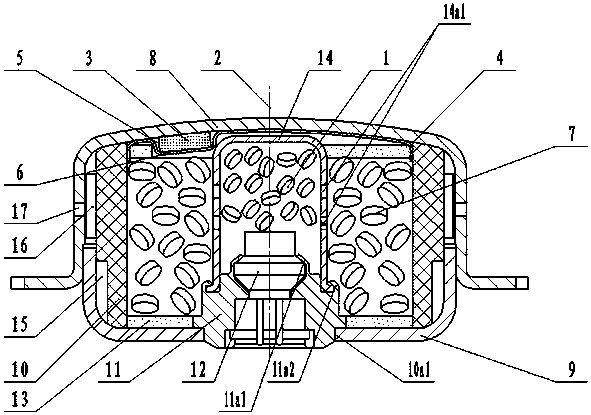

[0030] image 3 , 4 , 5, 6, 7, and 8, the present invention includes an upper shell 8, a lower shell 9, a base 11, an electric squib 12, a filter screen 10, a buffer pad 13, a stamped ignition shell 14, a PBKN sheet transmission Gunpowder 1, a combustion chamber cover 4 with an offset groove 5, wherein the bottom opening 9a1 of the lower shell 9 is equipped with a metal base 11, which is fixed by laser welding, and the base 11 is an electric squib 12 and an ignition shell The body 14 provides fixed support, the electric squib 12 is connected with the base 11 through the small closing opening 11a1, the ignition shell 14 is connected with the base 11 through the large closing opening 11a2, the inner diameter of the upper shell 8 is slightly smaller than the outer diameter of the lower shell 9, and the lower shell The opening end of the body 9 is embedded in the upper casing to form a round cake-shaped gas generator, and the filter screen 10 is a stepped cylindrical structure; o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com