Simple bridge damaging device

A simple and air hammer technology, applied in the direction of packaging, transportation and packaging, containers, etc., can solve the problems of powder not feeding, losing fluidity, not feeding, etc., to achieve simple structure, efficient destruction of broken bridges, efficient and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

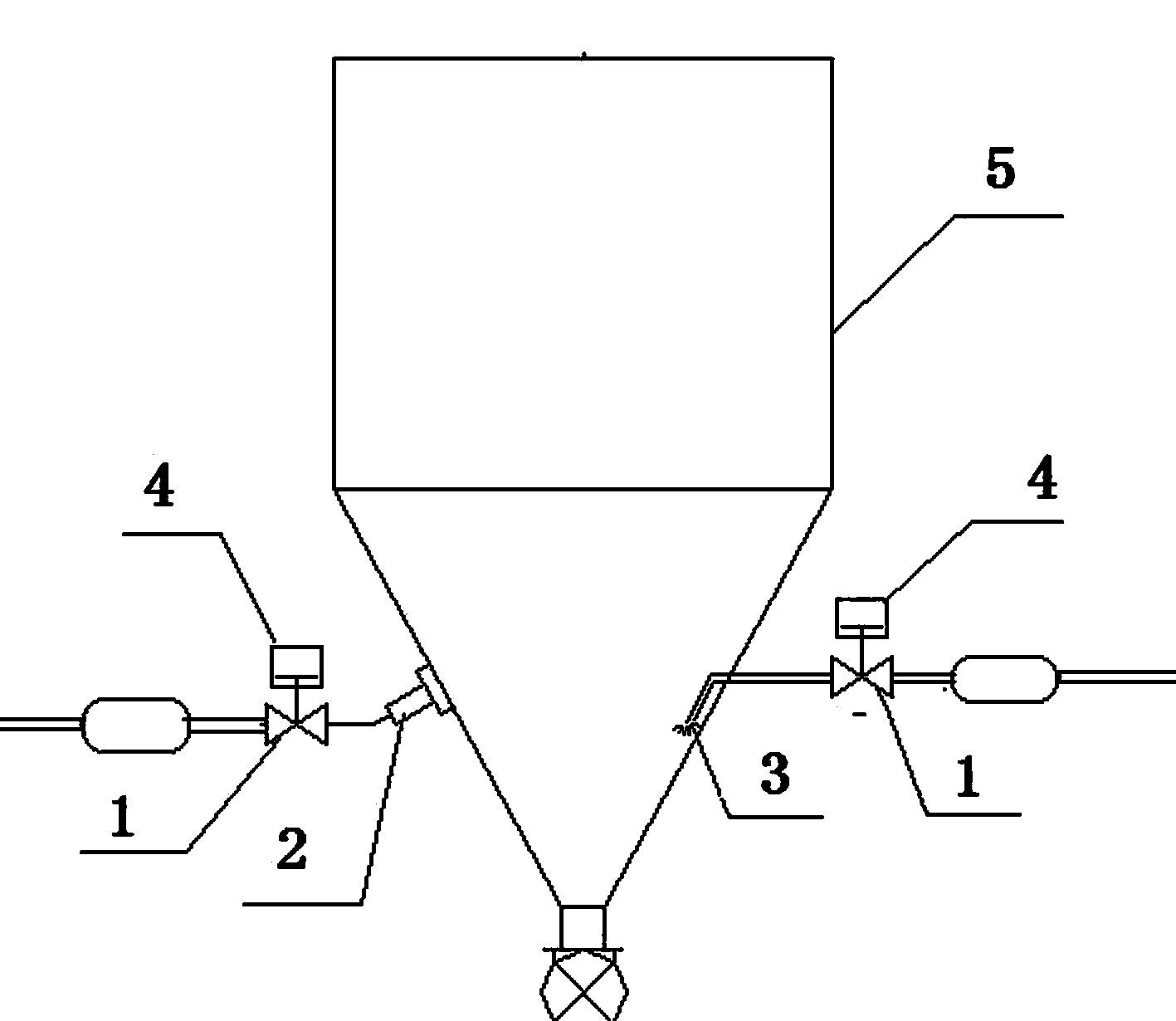

[0009] Such as figure 1 As shown, the simple bridging destruction device includes an air hammer 2, a nozzle 3, and a controller 4. The air hammer 2 and the nozzle 3 are respectively connected to a high-pressure air source through a valve 1. The controller 4 can control the start or close of the valve 1. The valve 1 is an electromagnetic valve; the air hammer 2 is installed on the outer wall of the material storage tank 5, and the nozzle 3 is mounted on the inside of the material machine 5.

[0010] Working principle: The controller 4 can open or close the valve 1 regularly. The high-pressure gas passes through the opened valve 1 to start the air hammer 2 to vibrate, enter the nozzle 3 to purge the inside of the material storage tank 5, and close the valve 1. The high-pressure gas cannot pass through the valve 1. The air hammer 2 does not vibrate, the nozzle 3 does not blow out high-pressure gas, and the valve 1 can be opened or closed at any time through the controller 4 manua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com