Silent buffer spring bolt structure

A lock tongue and mute technology, applied in building construction, building locks, buildings, etc., can solve problems such as noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

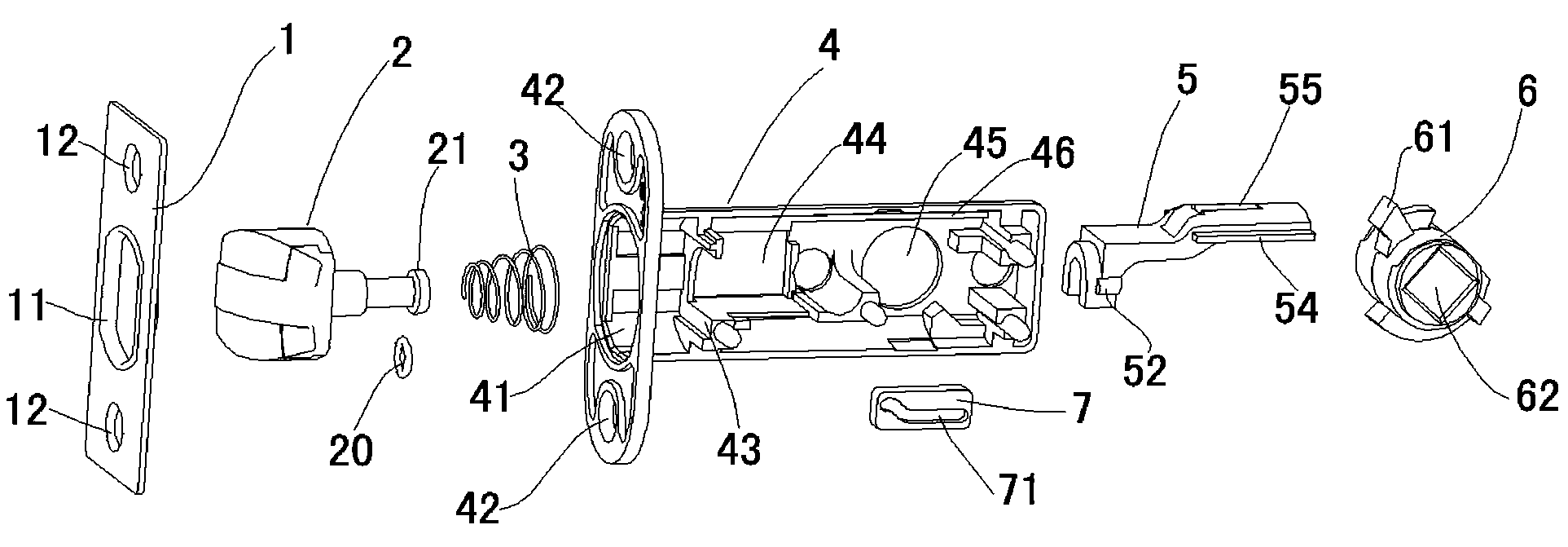

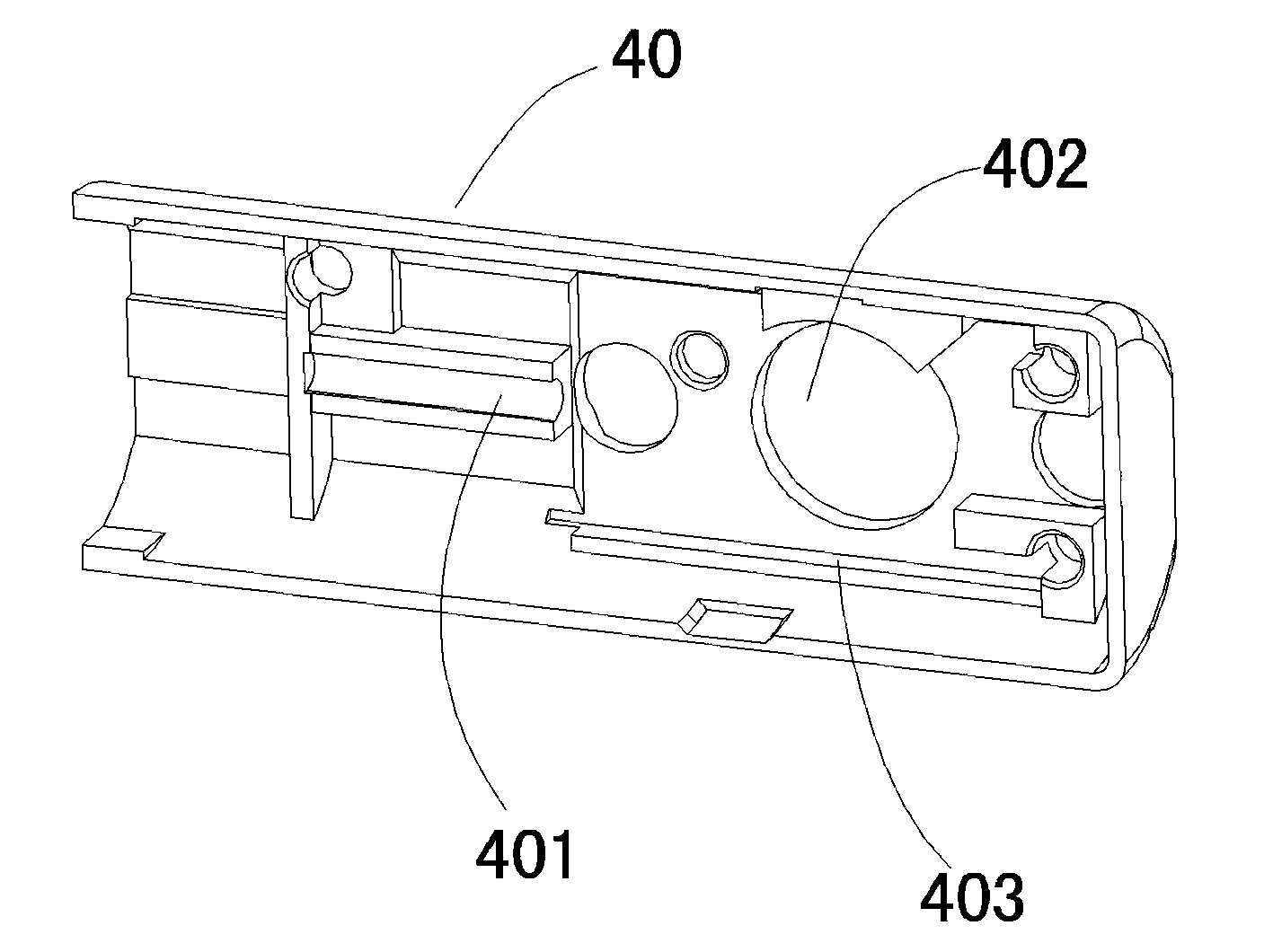

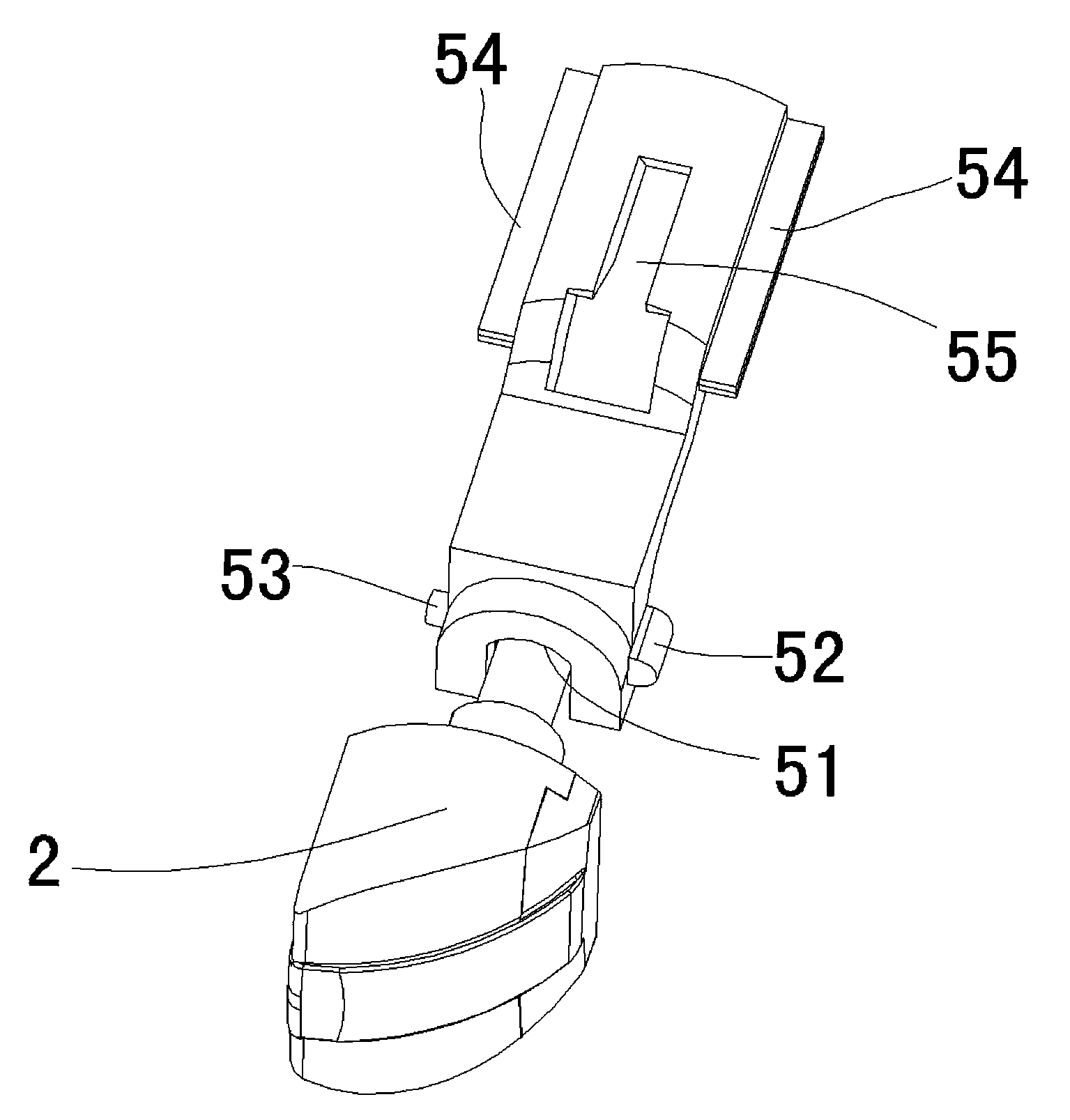

[0022] Such as Figure 1 to Figure 4 As shown, the present invention is provided with a lining plate 1, a oblique tongue 2, a bottom box 4, a slide block 5, a dial peach 6, a buffer block 7; A fixing hole A 12; a tail nail 21 is provided at the rear end of the oblique tongue 2, and a rubber ring 20 can be embedded and fixed in front of the tail nail 21; the front end of the bottom box 4 is provided with a bolt hole B 41 and two fixing holes B 42 Corresponding to the bolt hole A 11 and the two fixing holes A 12 on the liner 1 respectively; a spring slot 43 is provided inside the bolt hole B 41, and the oblique bolt 2 can pass through the bolt hole A 11 and the bolt hole B 42 stretches into the bottom box 4, a return spring 3 is set, one end of which is pressed against the rear of the oblique tongue 2, and the other end is pressed against the spring slot 43; the middle of the bottom box 4 is provided with a buffer chamber 44, and the buffer block 7 It can be embedded in the buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com