Test device for simulating continuous punching shear loading

A test device and impact load technology, applied in the field of geotechnical engineering and geotechnical mechanics, can solve the huge difference in the ability to withstand dynamic load impact, the shear strength of the shear plane has a great influence, and the change of the shear plane strength is difficult to measure and other problems, to achieve the effect of compact device structure, convenient strength change and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

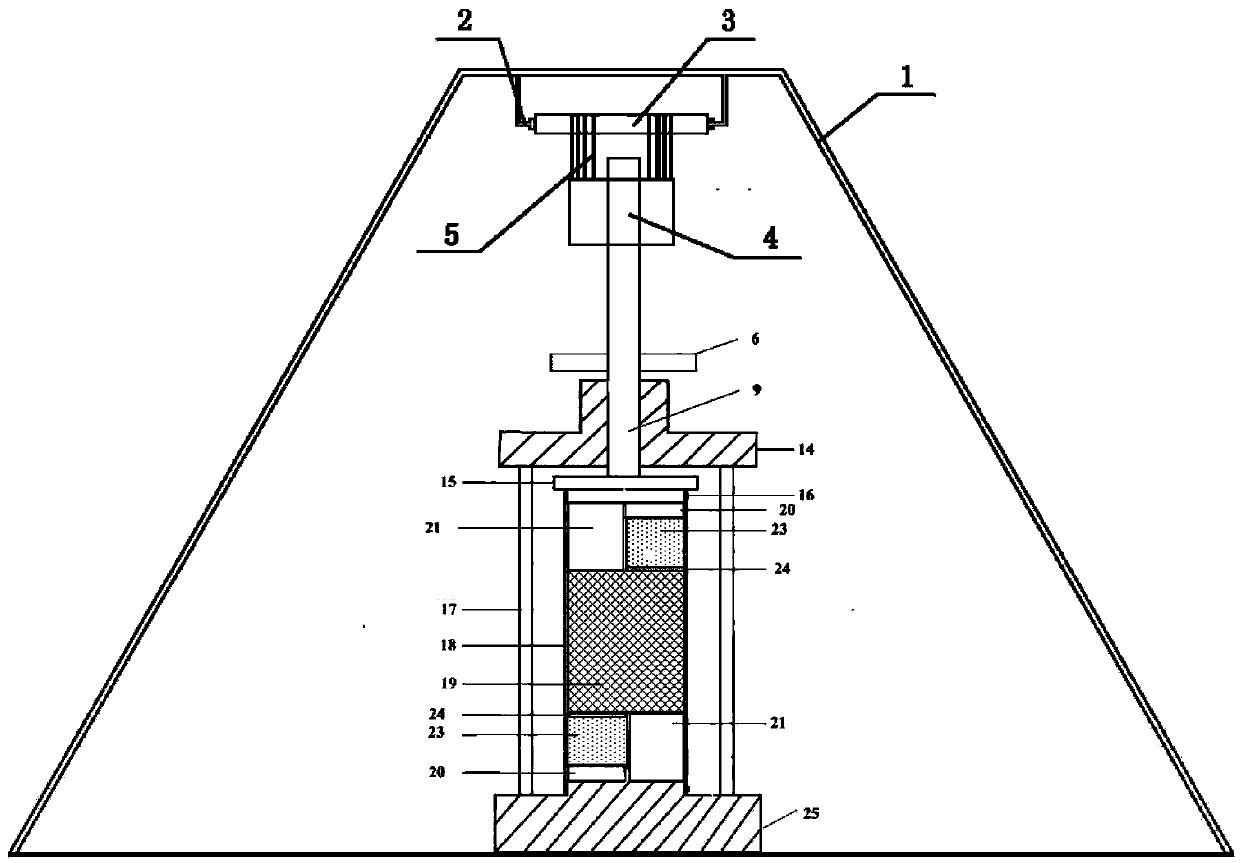

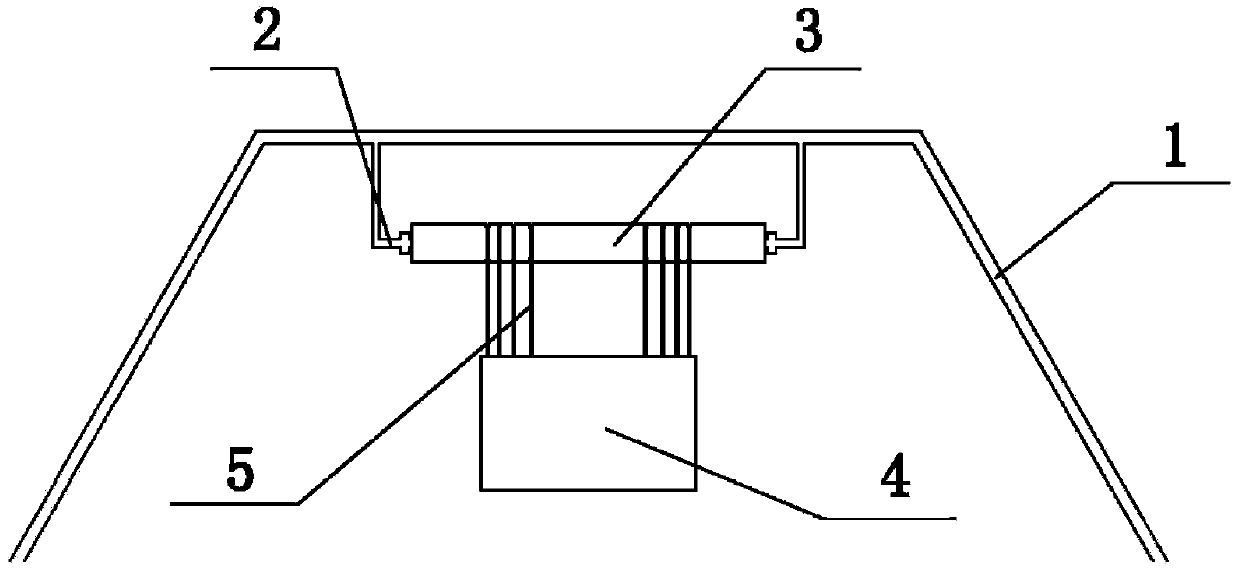

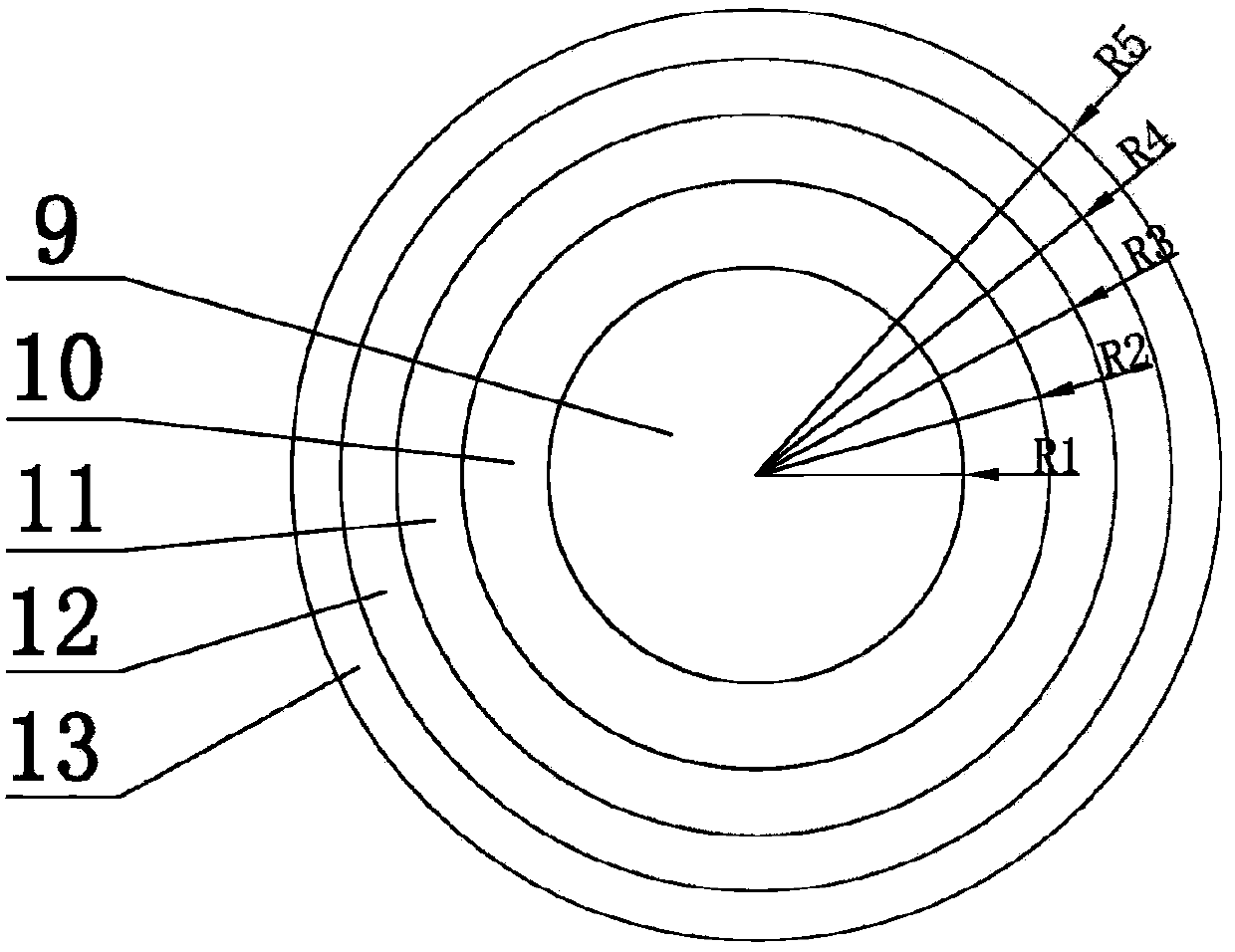

[0019] Embodiment: a kind of test device for simulating continuous impact shear loading, such as figure 1 As shown, including impact load mechanism and sample punching and shearing mechanism, impact load mechanism (such as figure 2 shown) includes steel truss 1, roller support 2, roller 3, drop weight 4, rope 5, cover plate 6 and center column 9, center column 9 passes through cover plate 6 longitudinally and is fixed, drop weight 4 consists of four 10; 11; 12; 13 are composed of collars 10; 11; 12; 13 whose radii increase sequentially but are equal in quality, and are nested on the top of the central column 9 from large to small, such as image 3 As shown, the outer diameter of the inner collar 10; 11; 12; 13 between two adjacent collars 10; 11; 12; 13 is equal to the inner diameter of the outer collar 10; 11; 12; 13, The central column 9 is a cylinder with a section radius of R1, the section of the collar 10; 11; 12; 13 is a ring, the inner and outer radii of the collar 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com