A Microwave Fluid Medium Detector

A fluid medium and microwave medium technology, applied in the field of microwave detectors, can solve the problem of not publicly measuring the dielectric constant of fluids and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

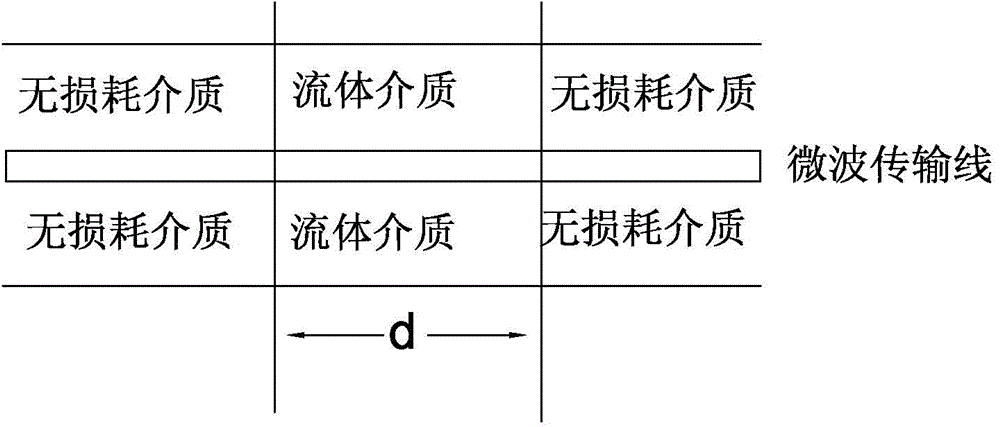

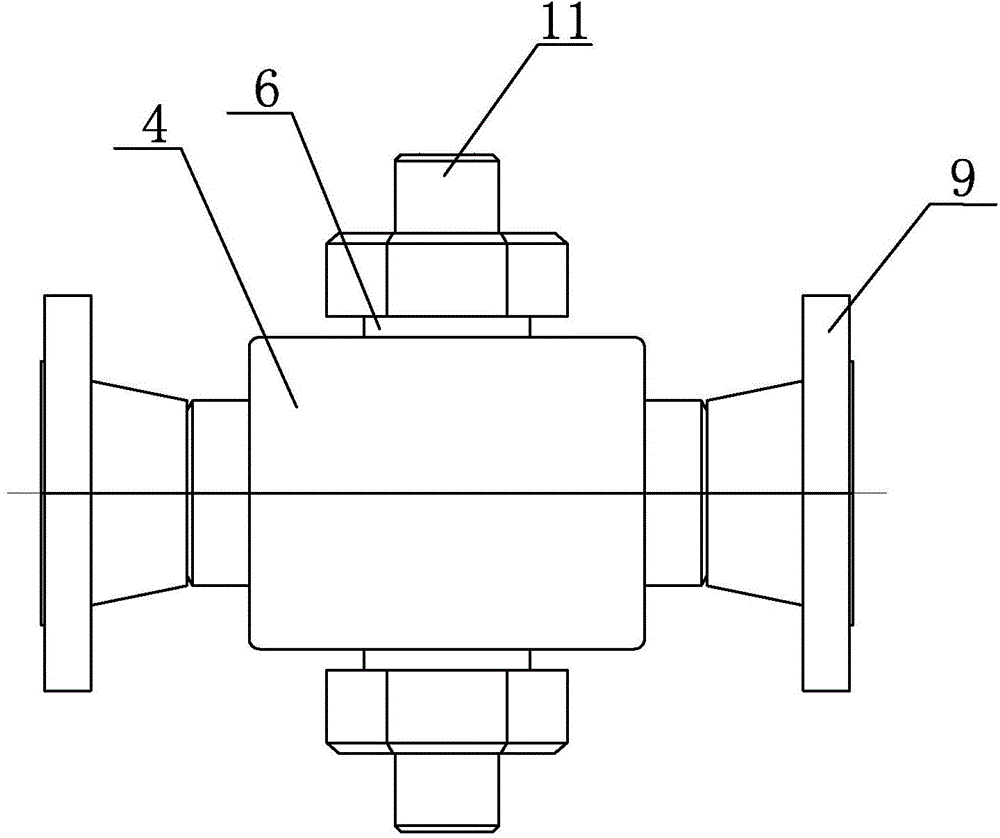

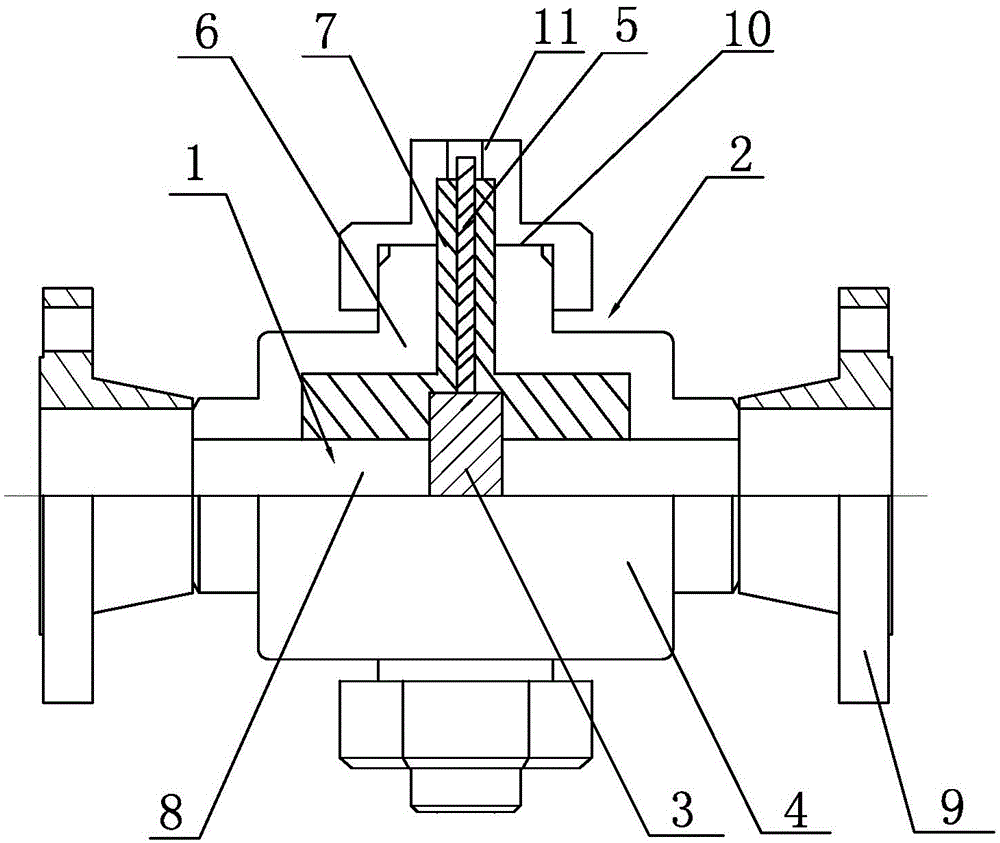

specific Embodiment 1

[0022] A microwave fluid medium detector, such as figure 2 , image 3 and Figure 4As shown, it includes a microwave transmission line. The microwave transmission line includes an open microwave transmission line 1 in the middle section and a closed microwave transmission line 2 on both sides. A first outer conductor 4 coaxial with an inner conductor 3, the enclosed microwave transmission line 2 includes a second inner conductor 5, a second outer conductor 6 sheathed on the outer periphery of the second inner conductor 5 and coaxial with the second inner conductor 5, and The low-loss microwave medium 7 is sealed and filled between the second inner conductor 5 and the second outer conductor 6, the second inner conductor 5 on both sides is connected with the first inner conductor 3 in the middle in a straight line, and the second outer conductor 6 on both sides is connected to the middle The first outer conductor 4 is integrally connected and forms a water flow through hole 8...

specific Embodiment 2

[0024] A microwave fluid medium detector, such as figure 2 , Figure 5 and Figure 6 As shown, it includes a microwave transmission line. The microwave transmission line includes an open microwave transmission line 1 in the middle section and a closed microwave transmission line 2 on both sides. A first outer conductor 4 coaxial with an inner conductor 3, the enclosed microwave transmission line 2 includes a second inner conductor 5, a second outer conductor 6 sheathed on the outer periphery of the second inner conductor 5 and coaxial with the second inner conductor 5, and The low-loss microwave medium 7 is sealed and filled between the second inner conductor 5 and the second outer conductor 6, the second inner conductor 5 on both sides is connected with the first inner conductor 3 in the middle in a straight line, and the second outer conductor 6 on both sides is connected to the middle The first outer conductor 4 is integrally connected and forms a water flow through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com