Hyperbolic cosine slit sensor for measuring water film thickness and design method of grid isolator

A hyperbolic cosine, water film thickness technology, applied in the field of testing, can solve the problems of steam turbine blade erosion and impact, steam turbine thermal efficiency reduction, blade roughness, etc., to achieve good electromagnetic performance and radiation performance, good flow characteristics, and low environmental requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

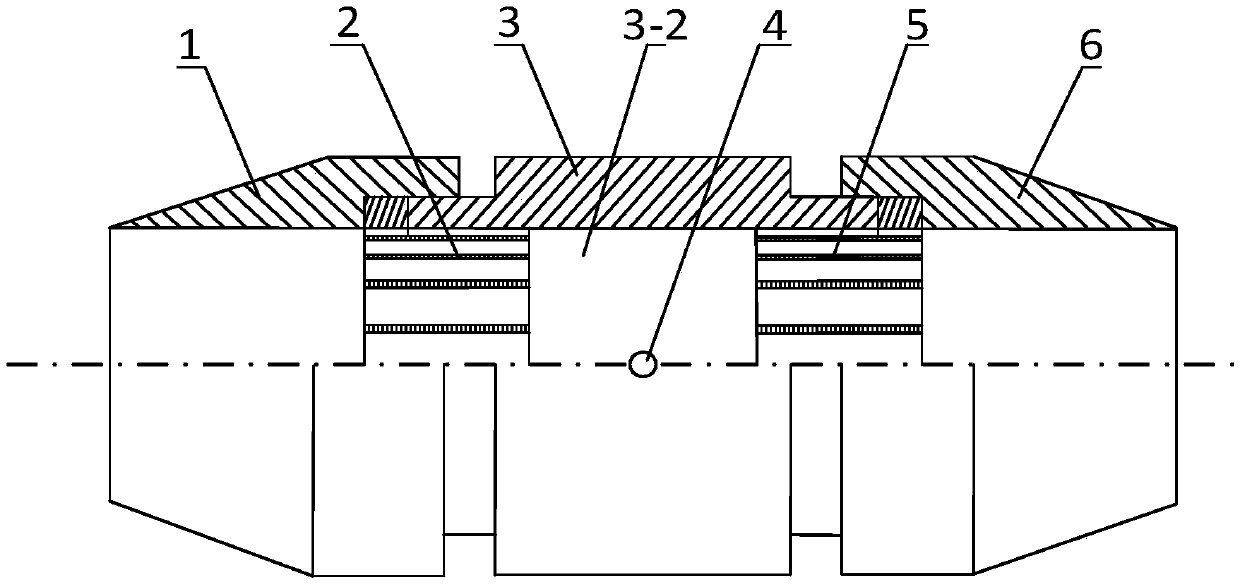

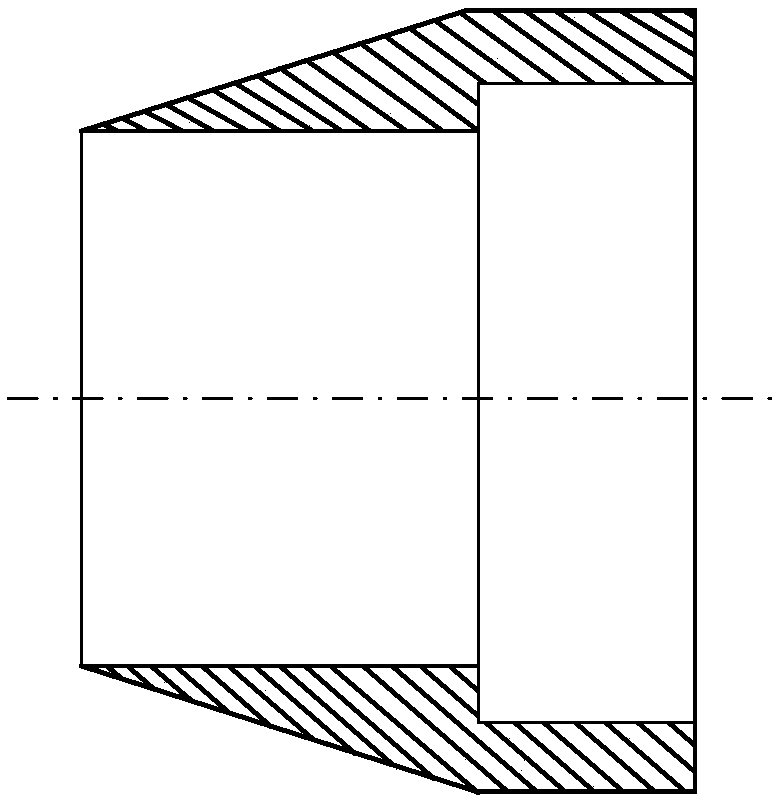

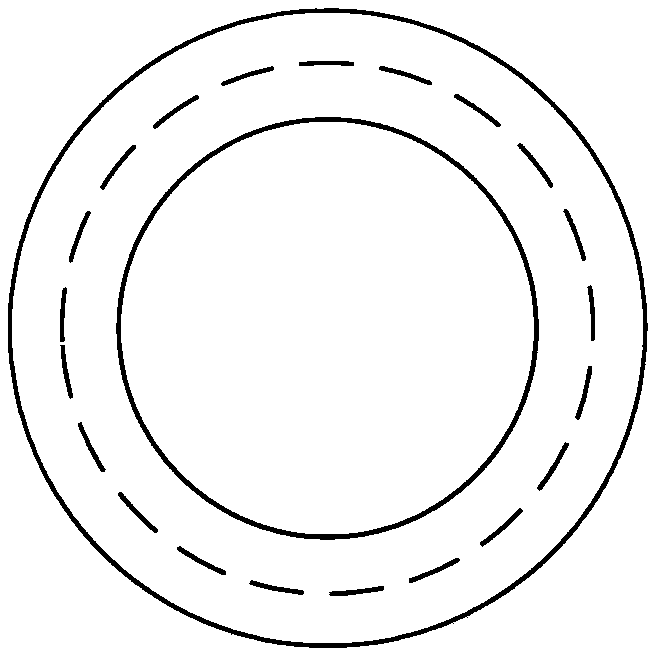

[0033] A hyperbolic cosine gap sensor for measuring water film thickness, comprising a resonant cavity main body 3, a wedge-shaped cylinder 1 at the left end, and a wedge-shaped cylinder 6 at the right end; The right grid isolator 5 is composed, the left and right ends of the resonant cavity 3-1 are respectively connected to the left grid isolator 2 and the right grid isolator 5, and the left grid isolator 2 and the right grid isolator 5 have the same structure, Both are composed of 9 metal strips; the middle metal strip of the 9 metal strips is linear, and the other 8 hyperbolic cosine-shaped metal strips are symmetrically distributed with respect to the middle metal strip; the left end of the left isolator 2 and the left wedge-shaped cylinder 1 The right end communicates with the wedge-shaped cylinder 6 at the right end; the side wall of the resonance cavity main body 3 is provided with a coupling installation hole 4 .

[0034] The grid spacer at the left end (2) and the gri...

Embodiment 2

[0058] A method for designing the grid isolator in the hyperbolic cosine gap sensor for measuring water film thickness described in Design Example 1, the design method of the grid isolator 2 at the left end and the grid isolator 5 at the right end are the same, and the grid isolator at the left end is isolated Device 2 includes the following specific steps:

[0059] Step 1: Calculate the direction of the current density at the end face of the resonator: set the x-axis through the center point of the grid isolator at the left end and coincide with the direction of the middle metal strip, and set the y-axis to be orthogonal to the x-axis; J r is the radial component of the current density at the end face of the resonator, is the tangential component of the current density at the end face of the resonant cavity, J is the current density at the end face of the resonant cavity; the current density J at the end face of the resonant cavity and the radial component J of the current d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com