A chemical liquid recovery device suitable for square substrates

A technology for recycling device and chemical liquid, applied in the field of chemical liquid recycling device, can solve the problems of chemical liquid pollution and dilution, and cannot be reused, and achieves the effects of rapid reaction, simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

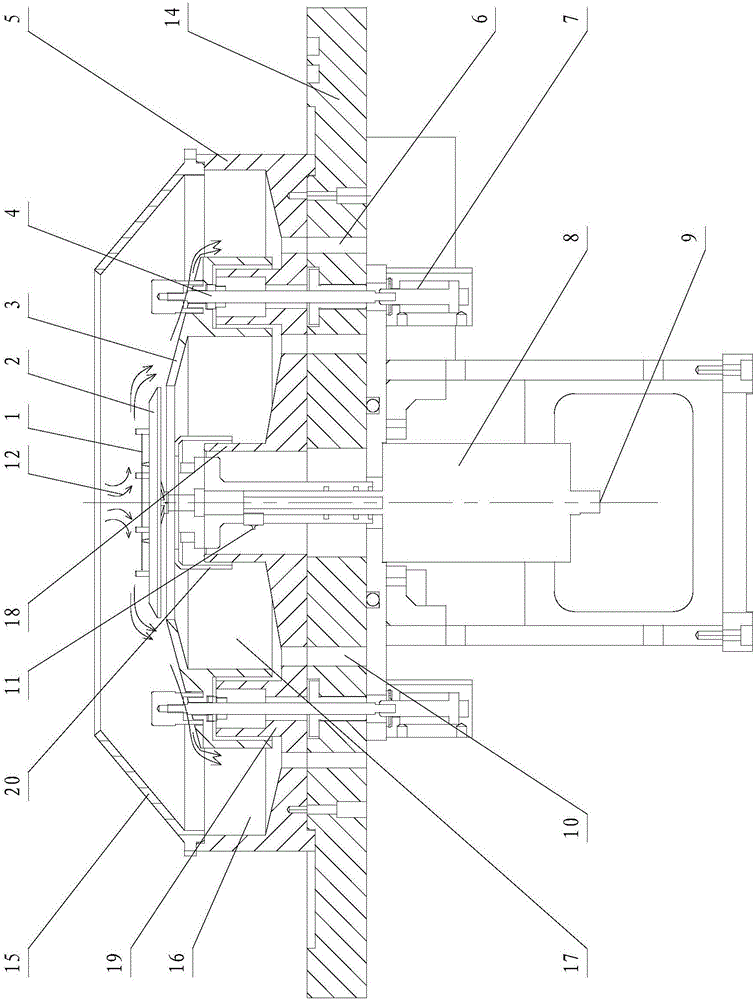

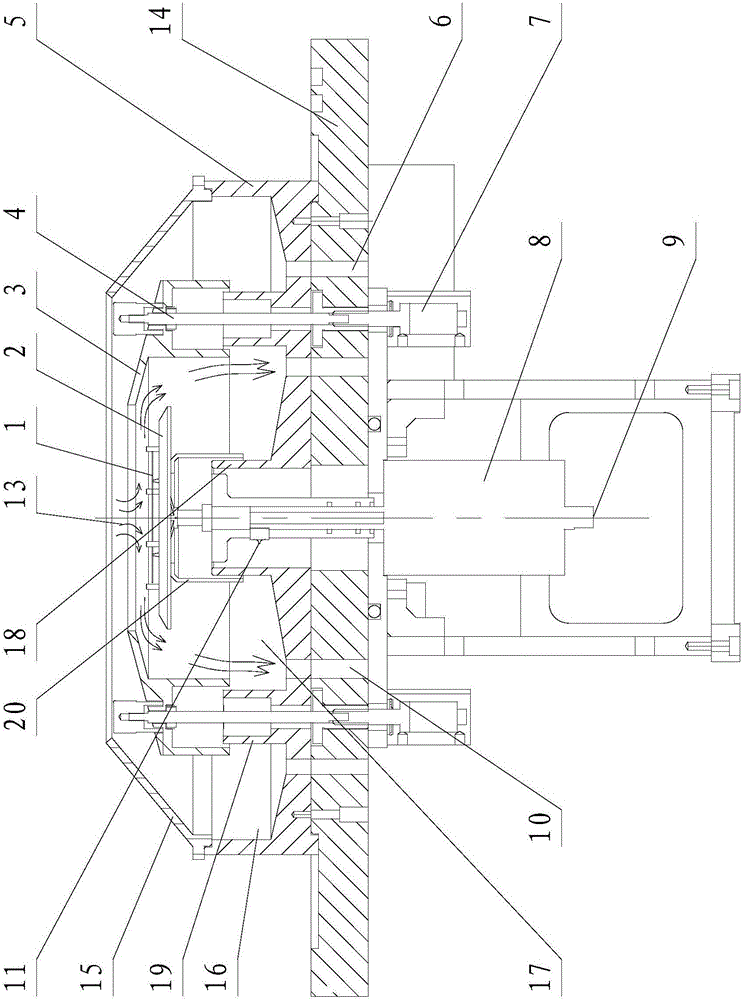

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

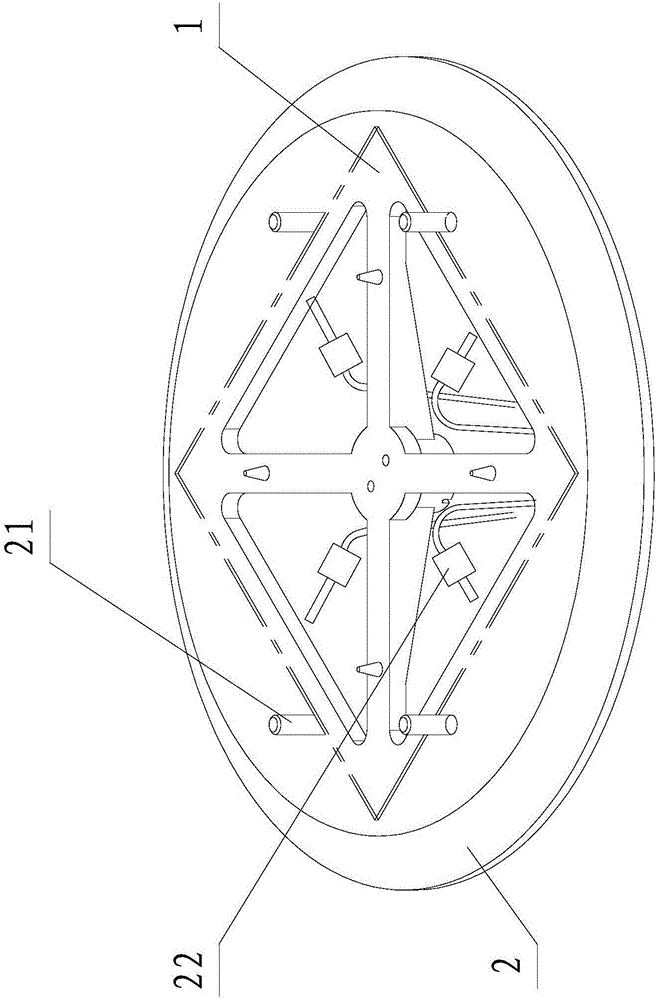

[0022] like figure 1 , figure 2 As shown, the present invention includes a square base plate 1, a chip holder 2, a CUP 3, a liquid receiving tank 5, a cylinder 7, a motor 8 and a table panel 14, wherein the liquid receiving tank 5 is fixed on the upper surface of the table panel 14, and the liquid receiving tank 5 The bottom surface of the bottom surface extends axially upwards, forming a hollow first protrusion 18 and a second protrusion 19 from the inside to the outside. The first protrusion 18 is located in the center of the liquid receiving tank 5, the central axis and the central axis of the liquid receiving tank 5 Collinear, the second protrusion 19 is located at the periphery of the first protrusion 18, and is concentrically arranged with the first protrusion 18, and an inner groove 17 is formed between the first protrusion 18 and the second protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com