Work vehicle

A technology for working vehicles and inverters, which is applied to vehicle components, hybrid vehicles, forklifts, etc., and can solve problems such as inability to perform driving actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

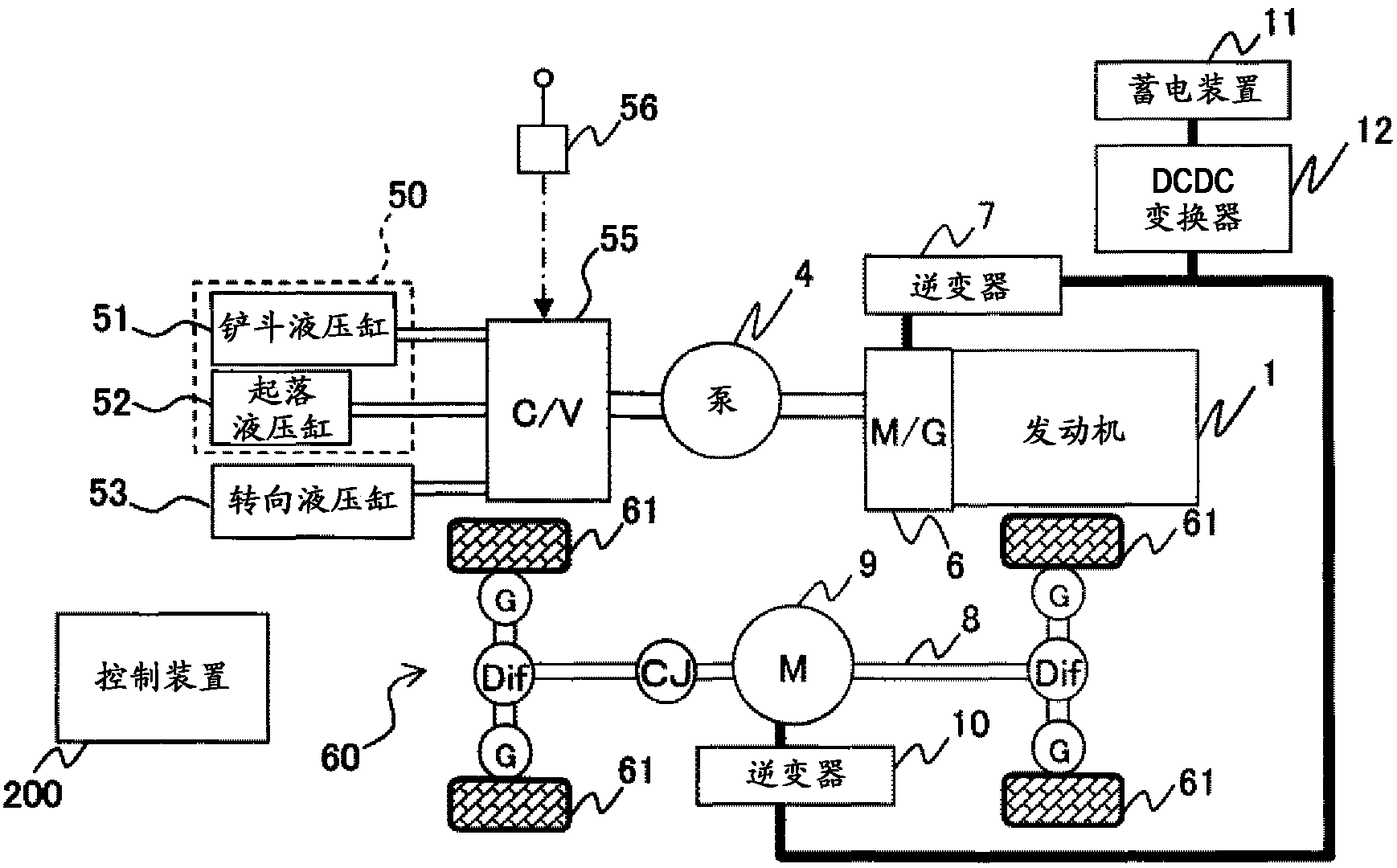

[0026] Embodiments of the present invention will be described below using the drawings. figure 1 It is a system configuration diagram of a hybrid wheel loader according to an embodiment of the present invention.

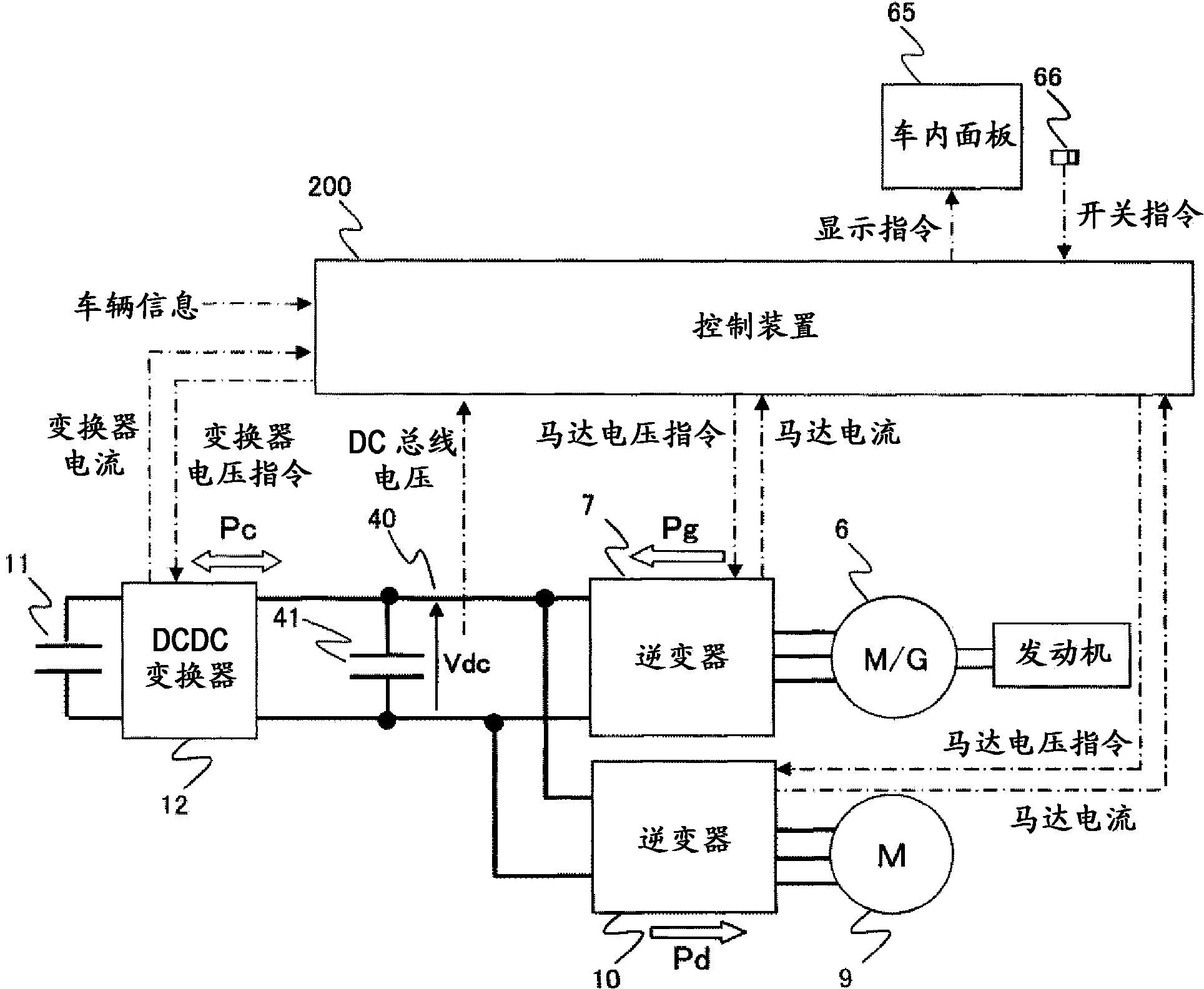

[0027] The wheel loader shown in this figure includes: a working device 50 with a bucket and a landing arm (not shown) and installed in front of the vehicle body; a diesel engine (internal combustion engine) 1; driven by the engine 1 and used to drive hydraulic actuators The hydraulic pump 4 of the mechanism (bucket hydraulic cylinder 51, lifting hydraulic cylinder 52, and steering hydraulic cylinder 53); the control valve 55 for controlling the hydraulic oil supplied from the hydraulic pump 4 to the hydraulic actuators 51, 52, and 53; The power storage device 11 for storing direct current power; the inverter devices 7 and 11 for converting direct current and alternating current; DC bus voltage between 7 and 11) to convert the DCDC converter device 12; through the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap