Patents

Literature

115results about "Forklift trucks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

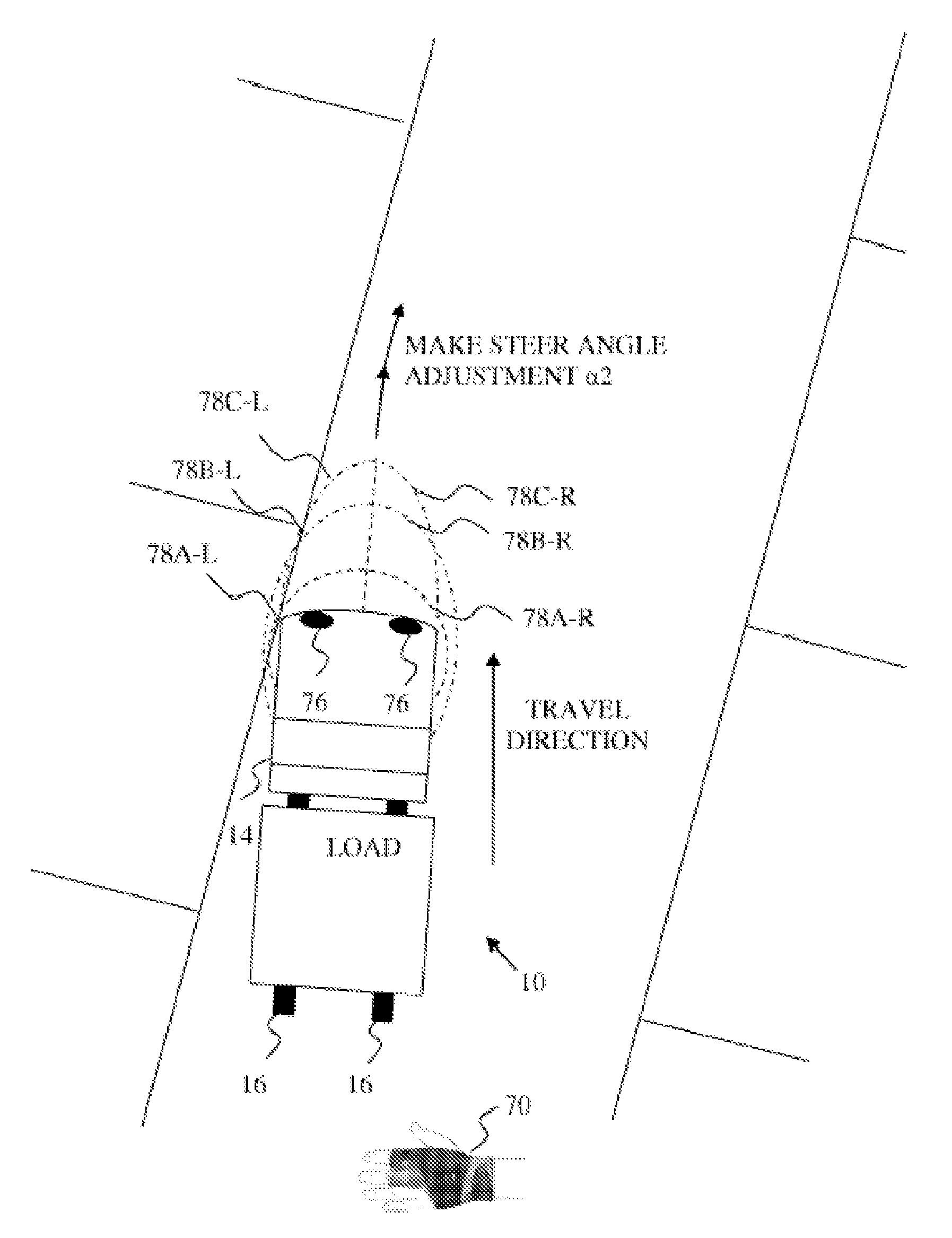

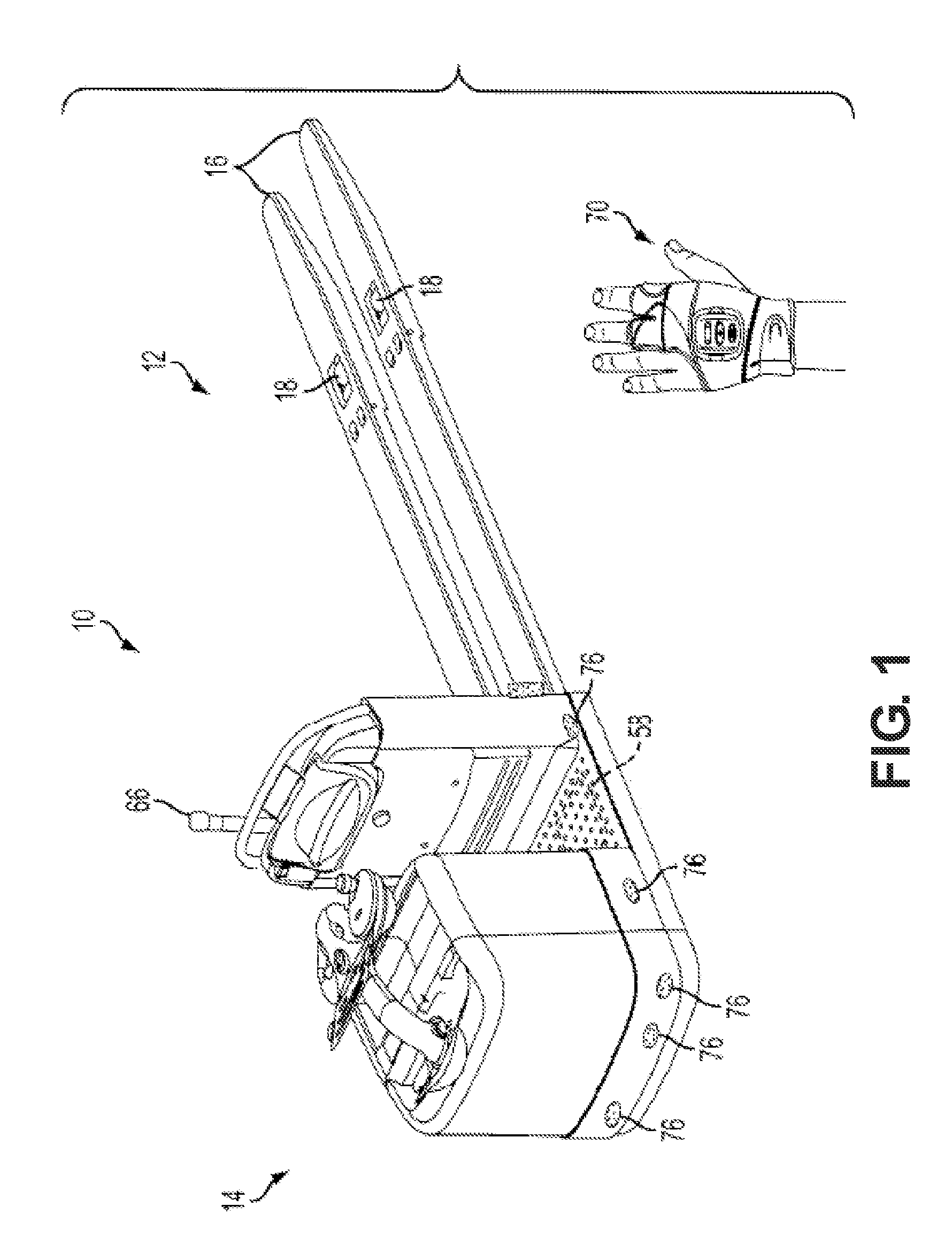

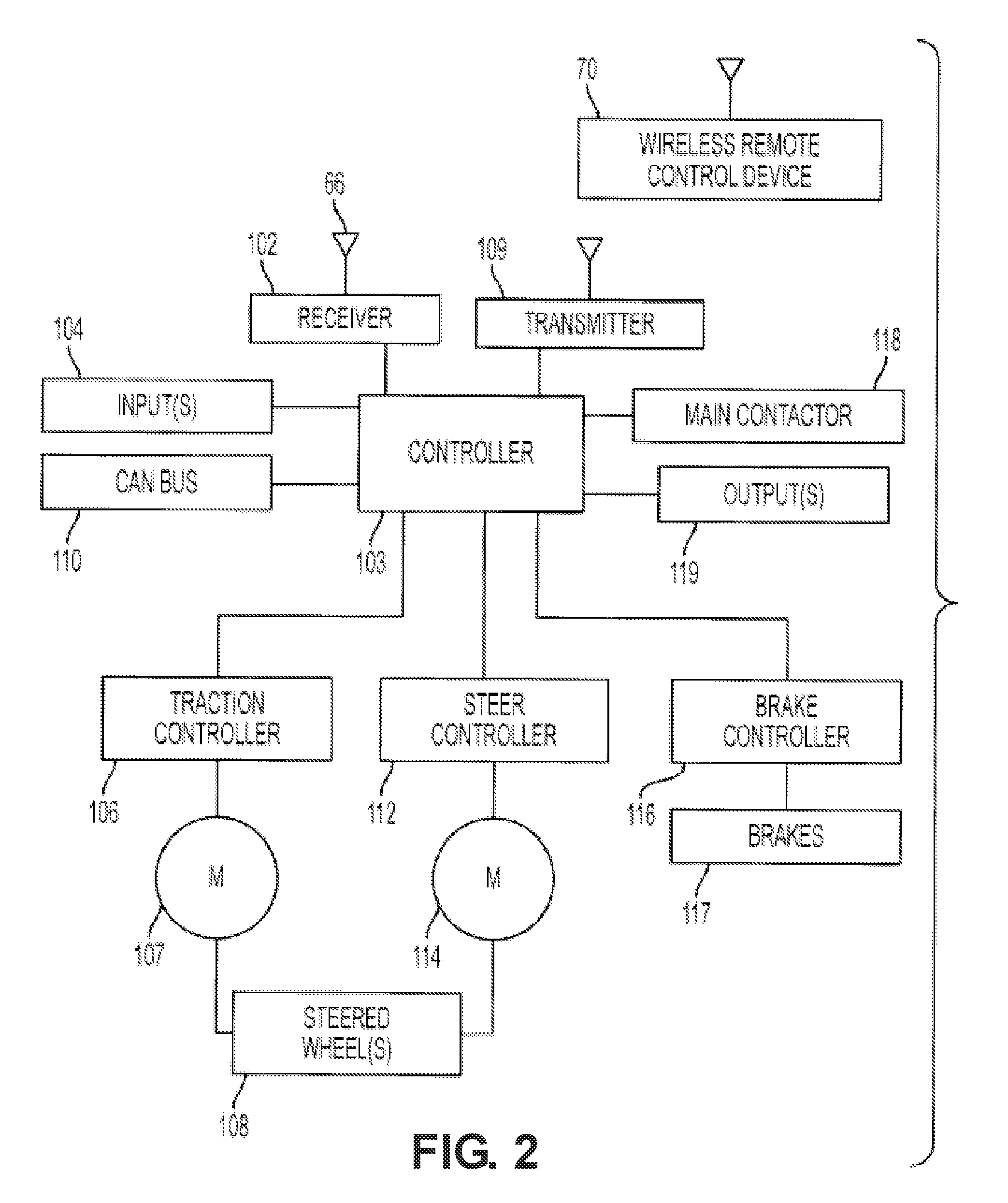

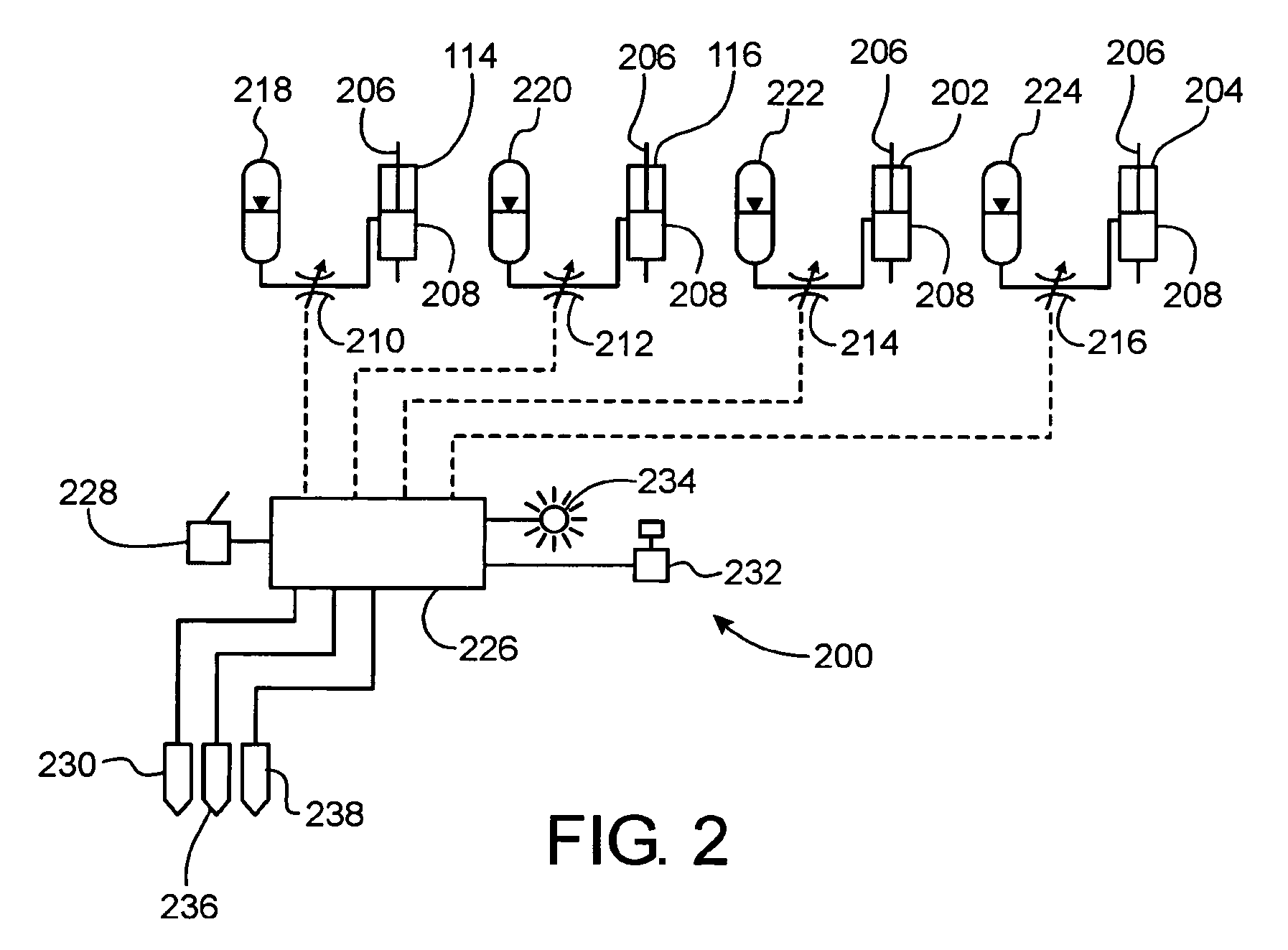

Multiple zone sensing for materials handling vehicles

ActiveUS20100114405A1Transmission systemsDigital data processing detailsSteering angleControl system

A supplemental control system for a materials handling vehicle comprises one or more sensors capable of defining multiple contactless detection zones at least towards the front of the forward travel direction of a remotely controlled vehicle. The vehicle responds to the detection of objects within the designated zones based upon predetermined actions, such as to slow down or stop the vehicle, and / or to take other action, such as to perform a steer angle correction.

Owner:CROWN EQUIP CORP

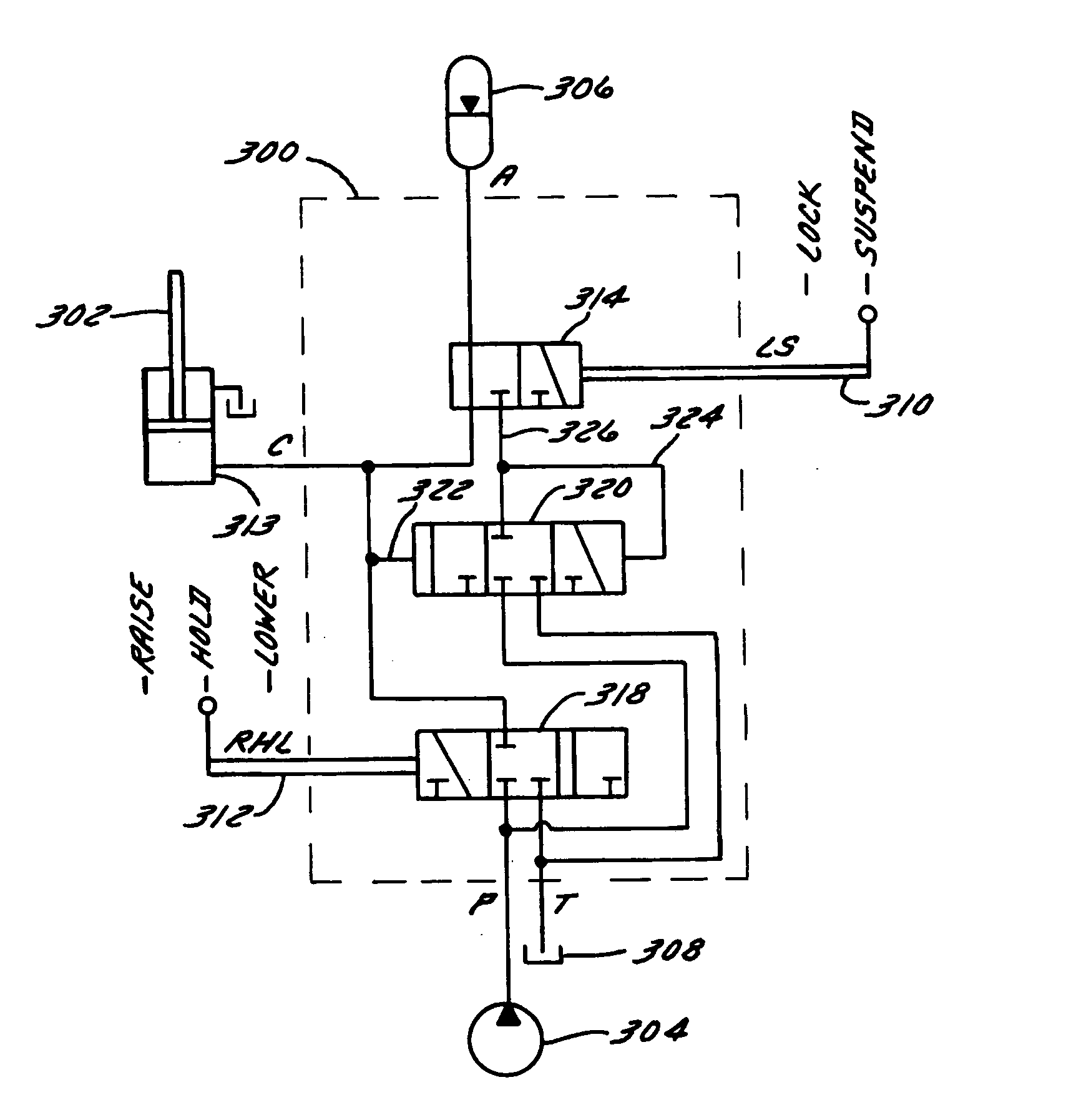

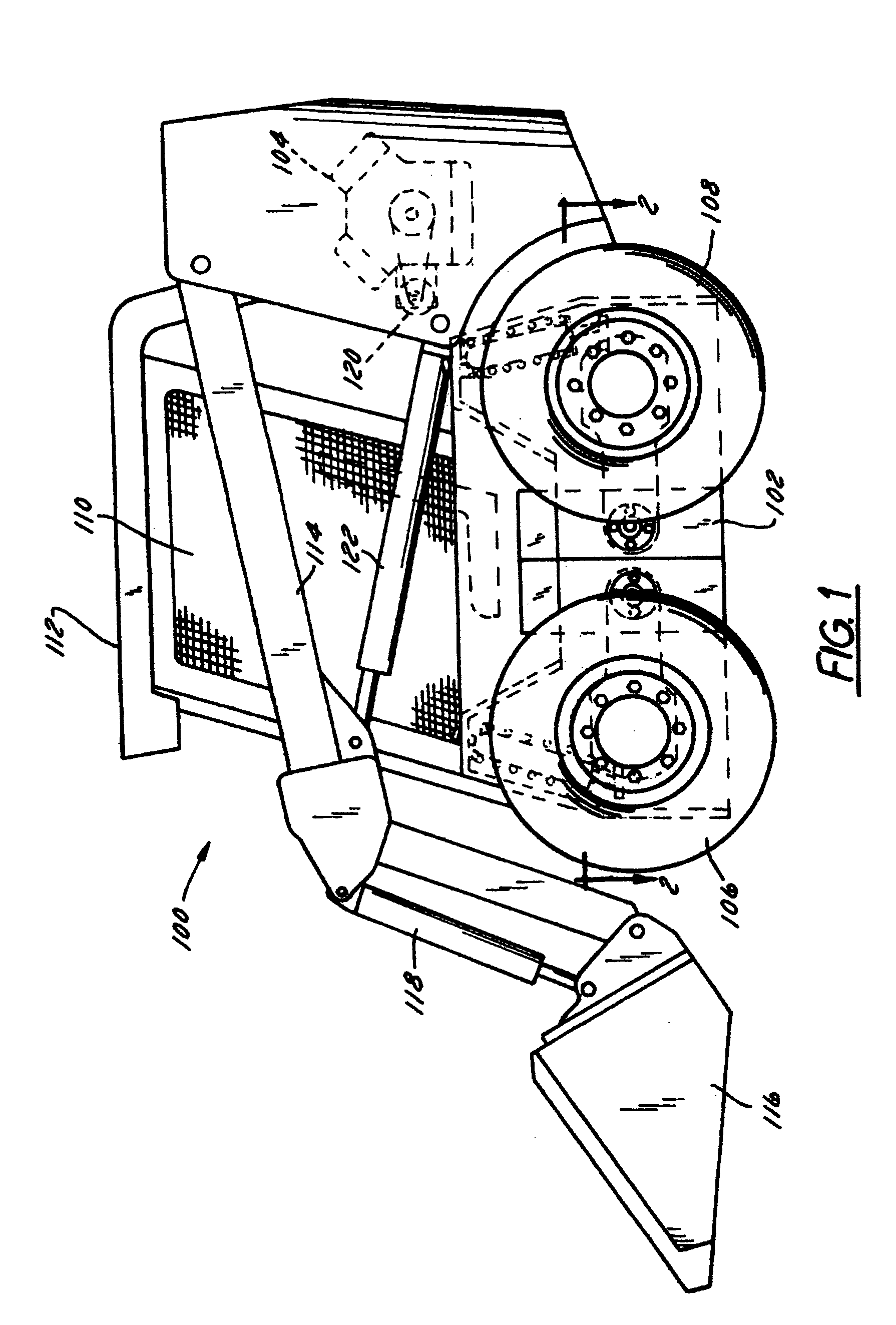

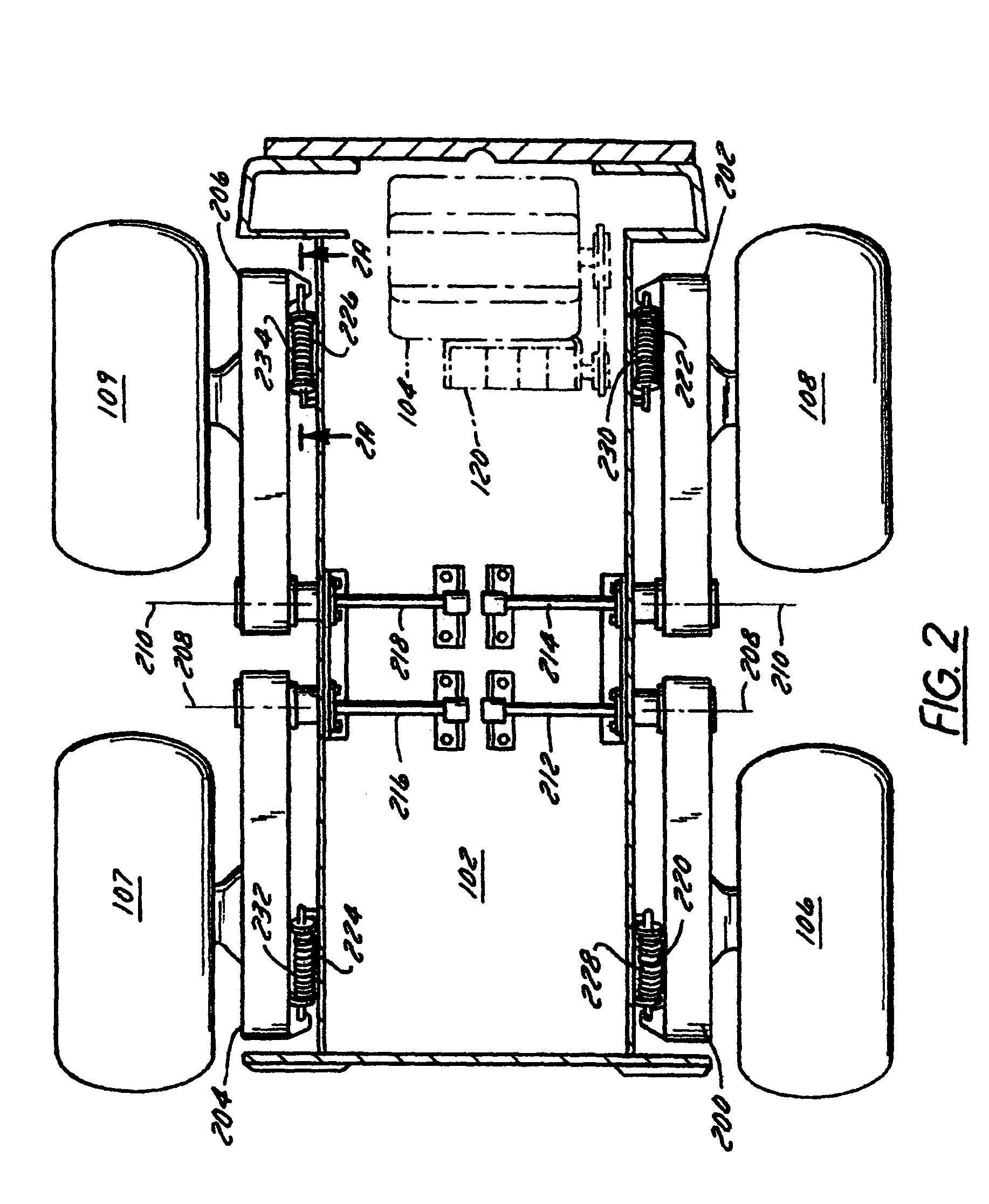

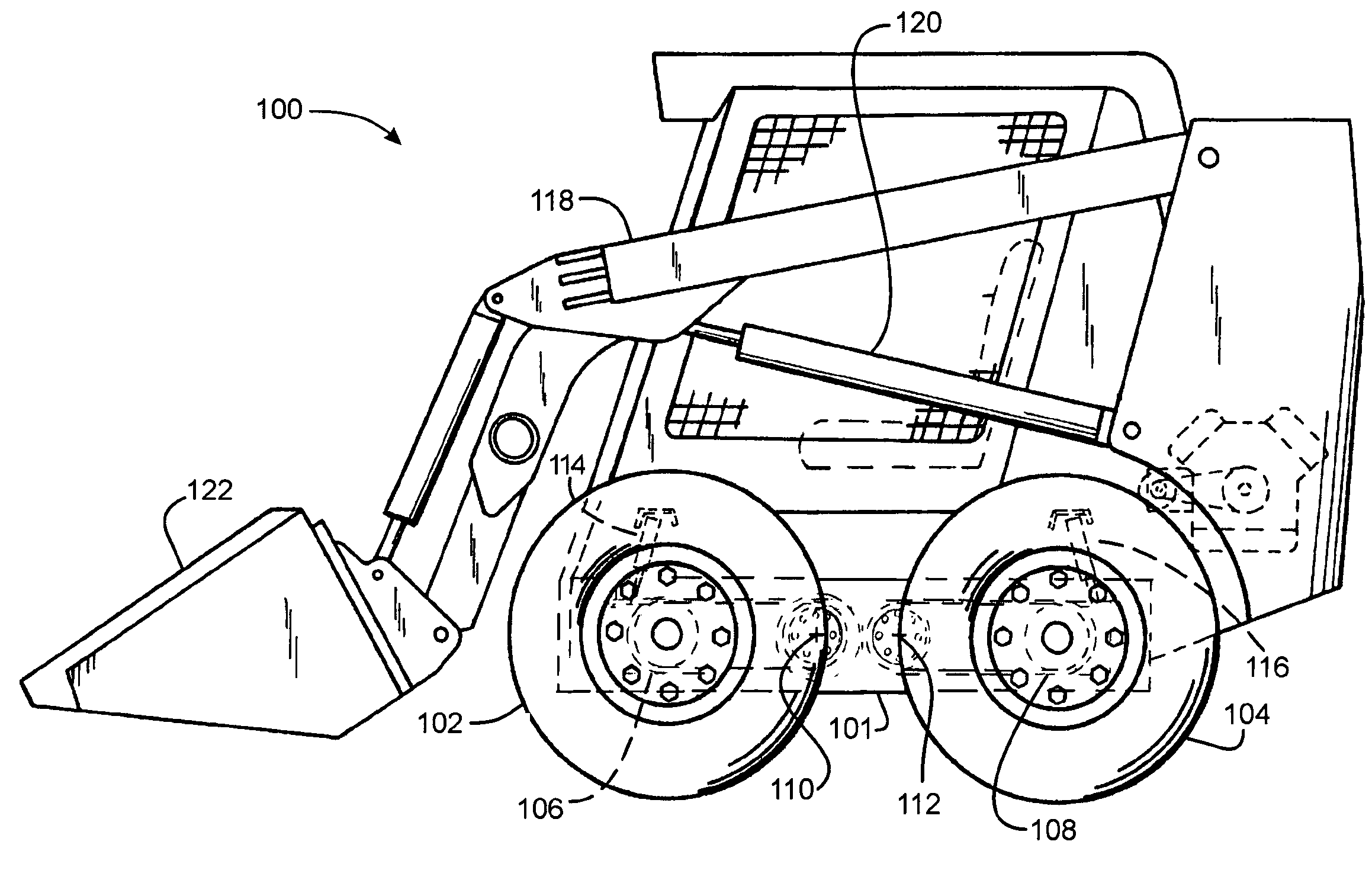

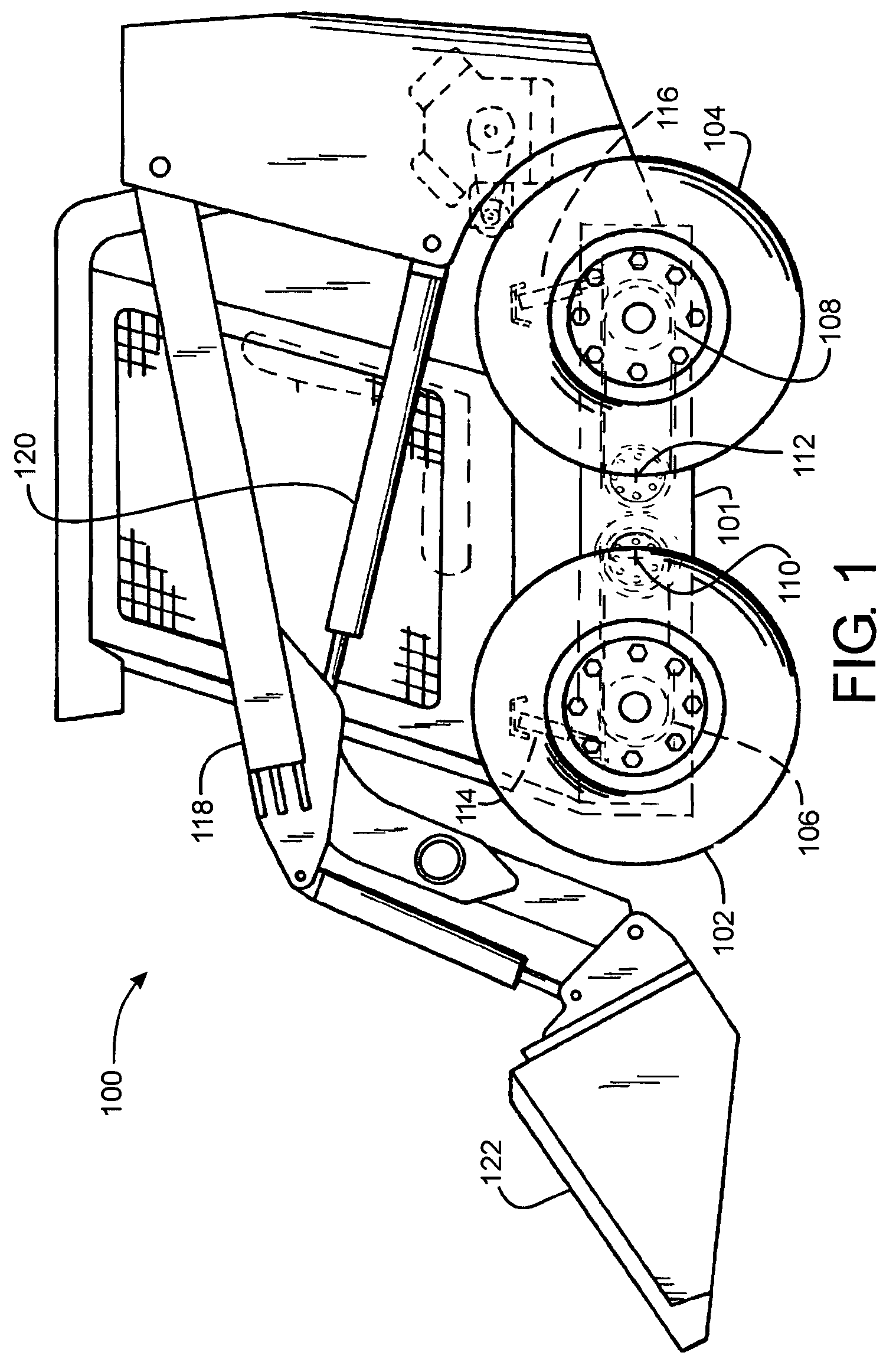

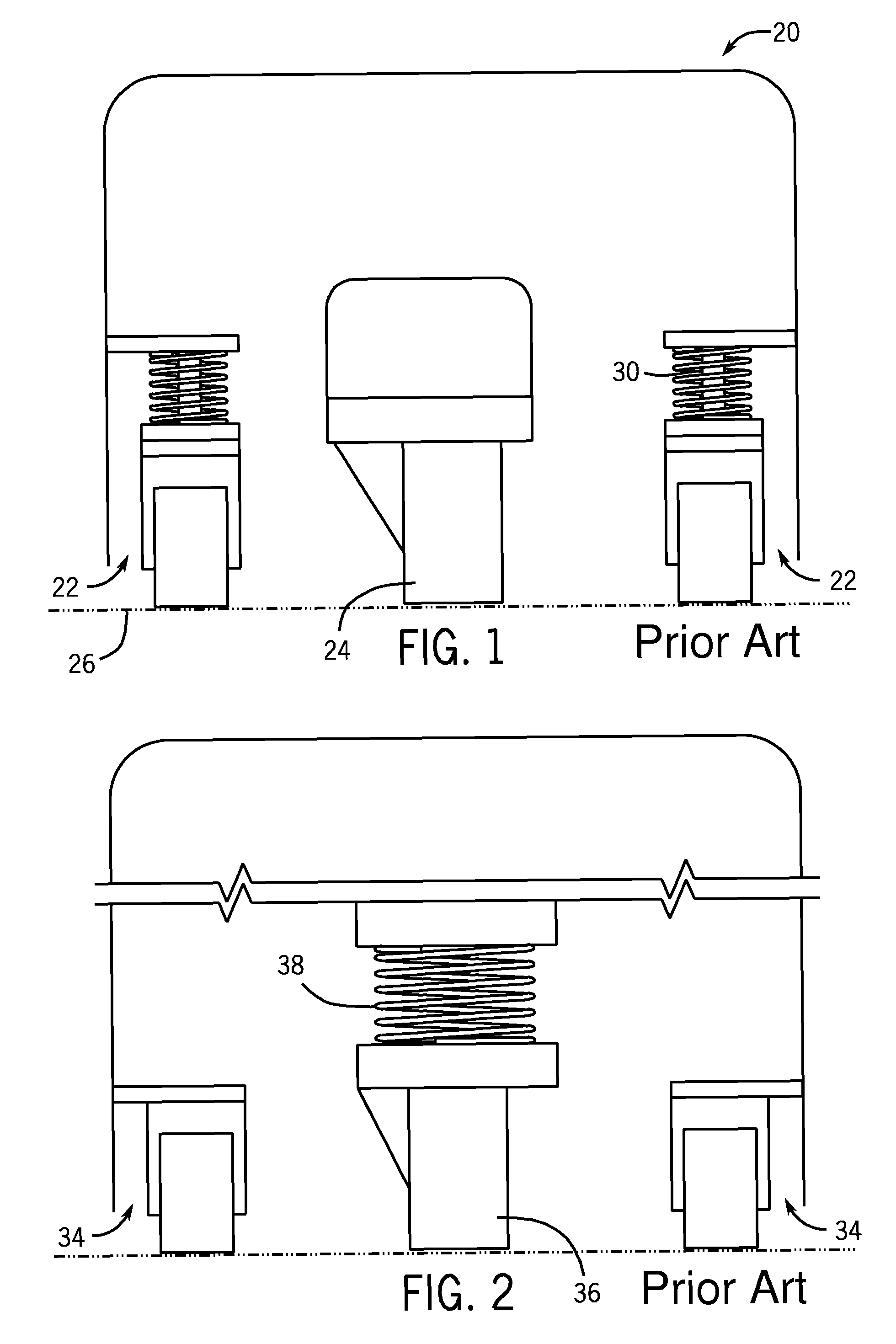

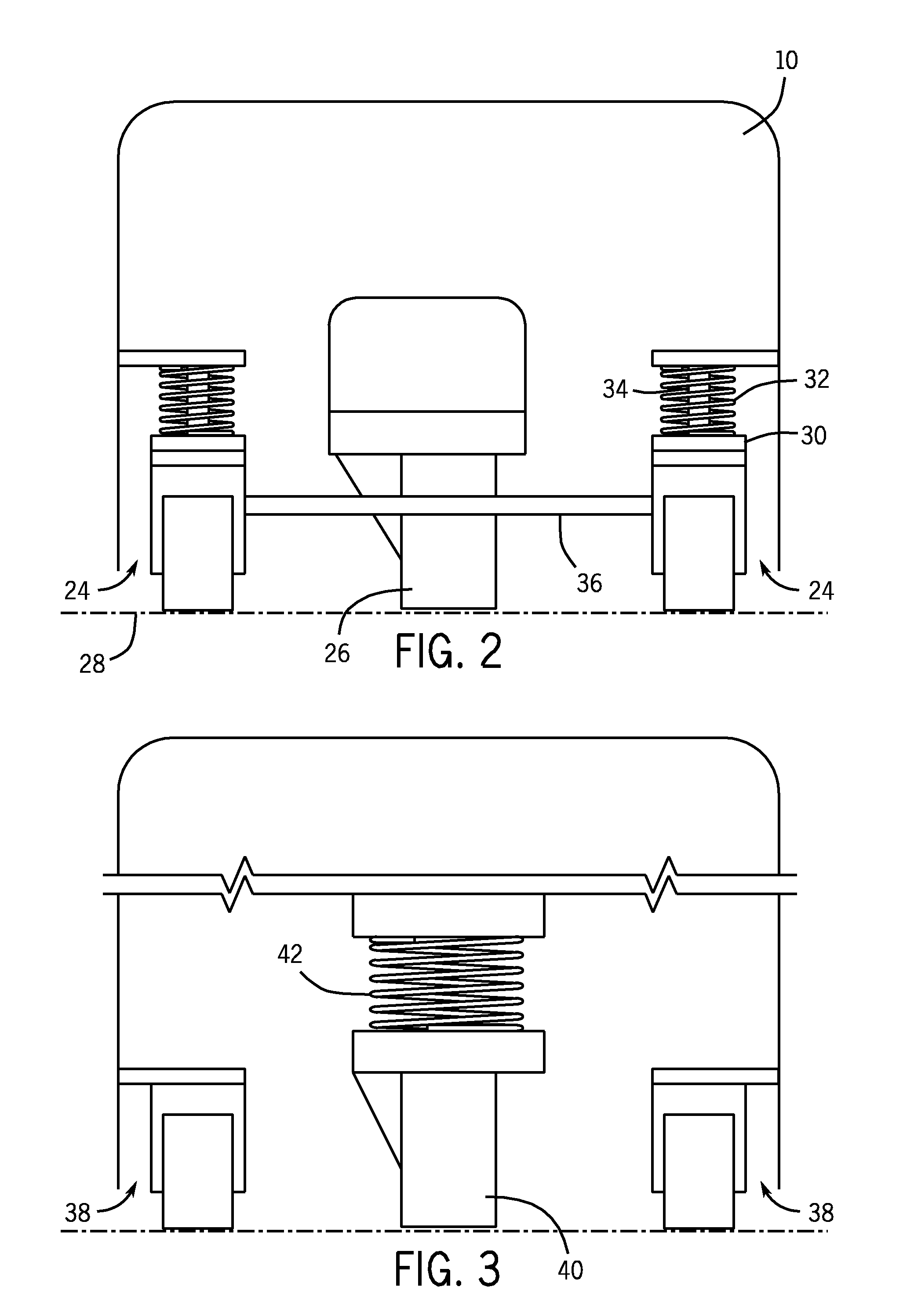

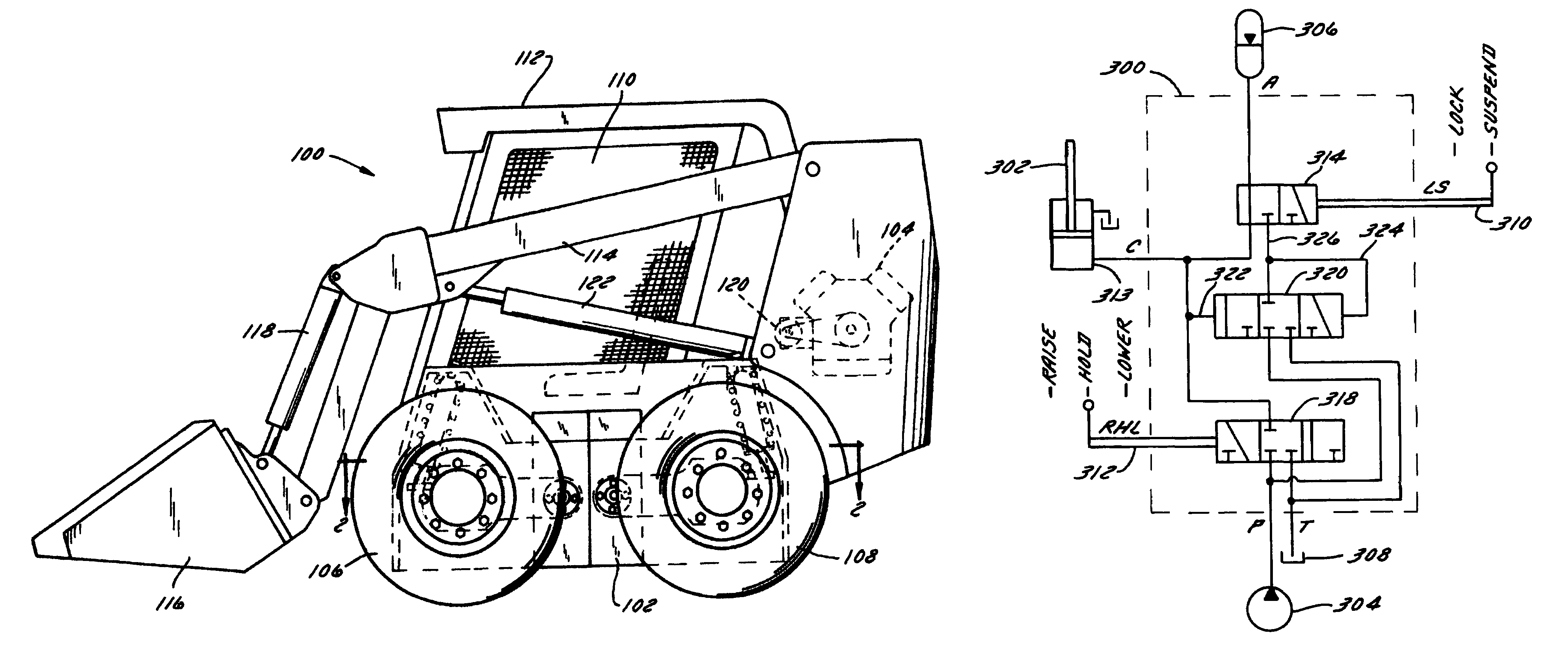

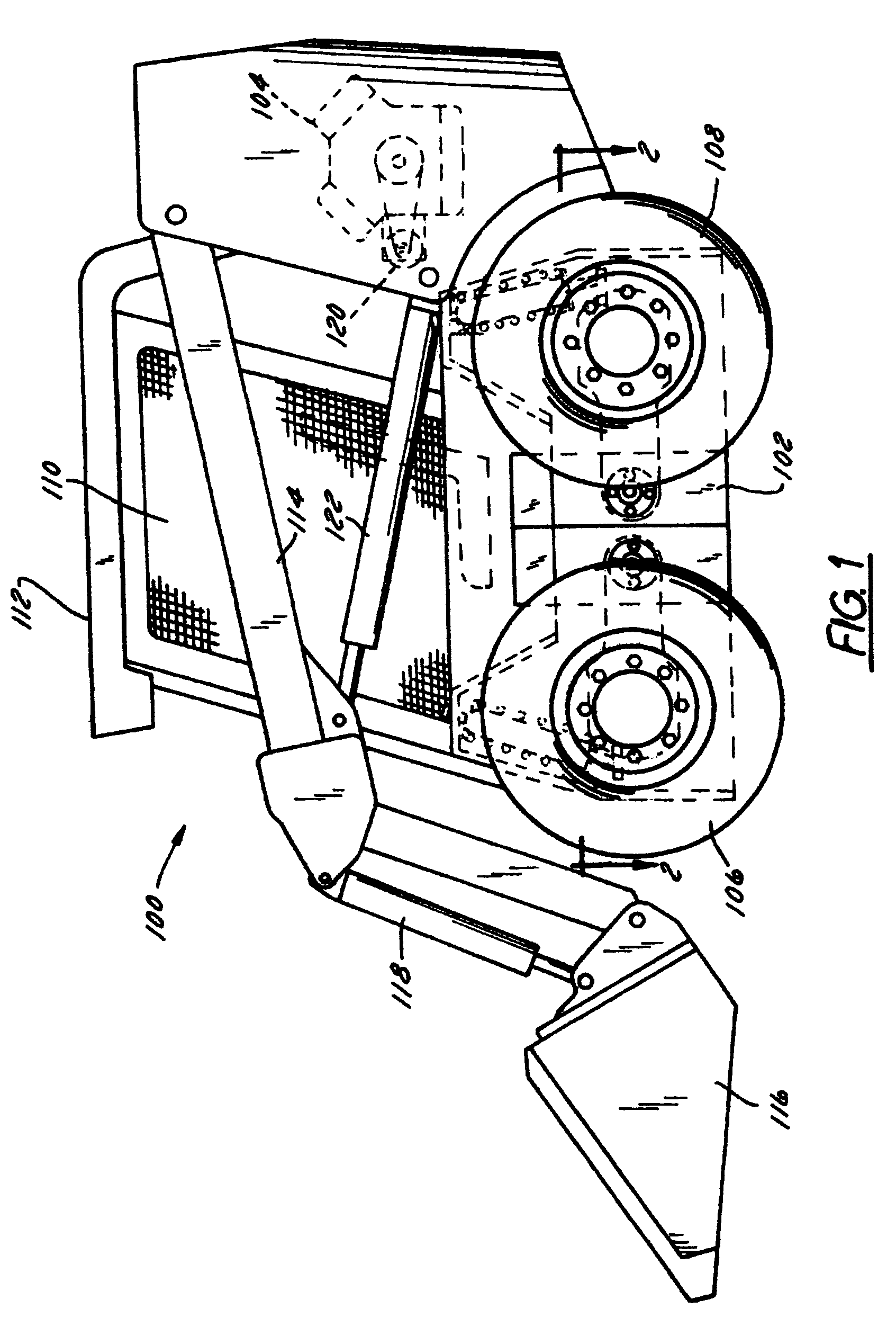

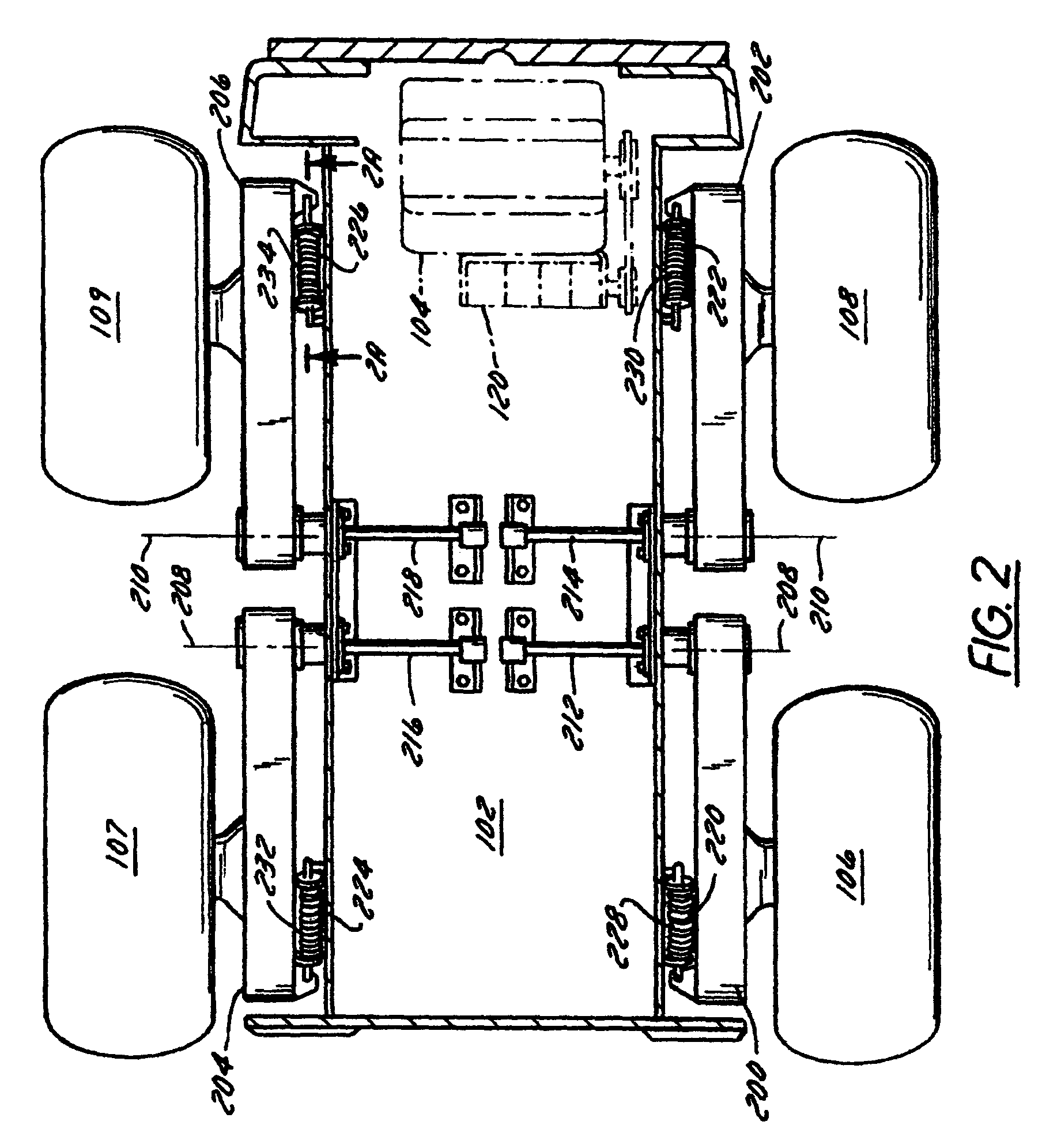

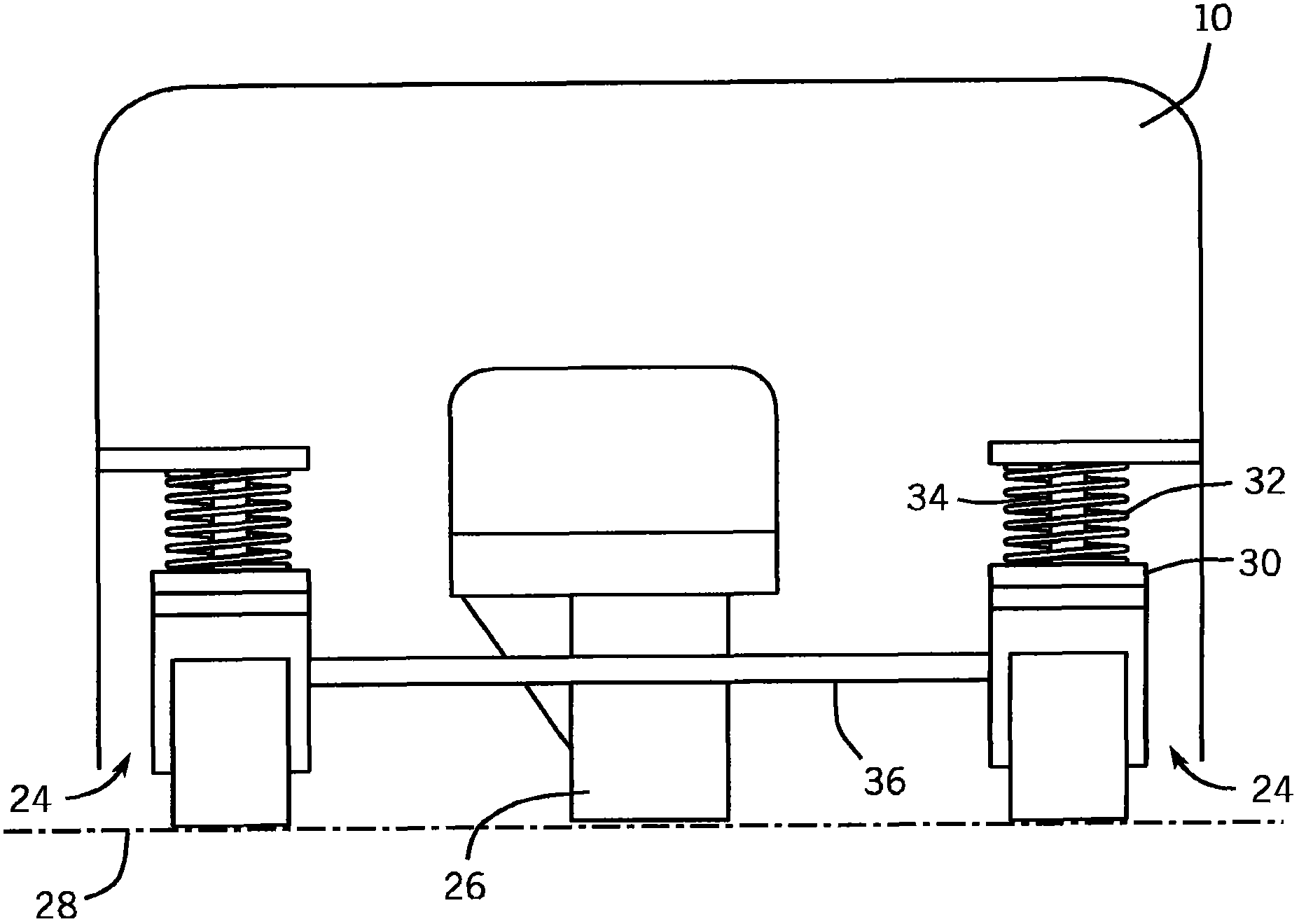

Locking anti-motion suspension

ActiveUS20050062239A1Effective lockingVehicle cleaning apparatusLoading/unloading vehicle arrangmentHydraulic cylinderControl arm

A skid steer vehicle has a suspension that includes a control arm pivotally coupled to the vehicle chassis that is supported by a hydraulic cylinder connected to an accumulator to provide springing. A hydraulic circuit coupled to the cylinder and accumulator permit the operator to raise and lower the chassis, to lock the suspension while the vehicle is loaded, and to automatically charge or discharge the accumulator to match the cylinder pressure during loading and unloading. In this manner, when the suspension is unlocked after loading, the vehicle chassis neither rises nor falls.

Owner:CNH IND AMERICA LLC +1

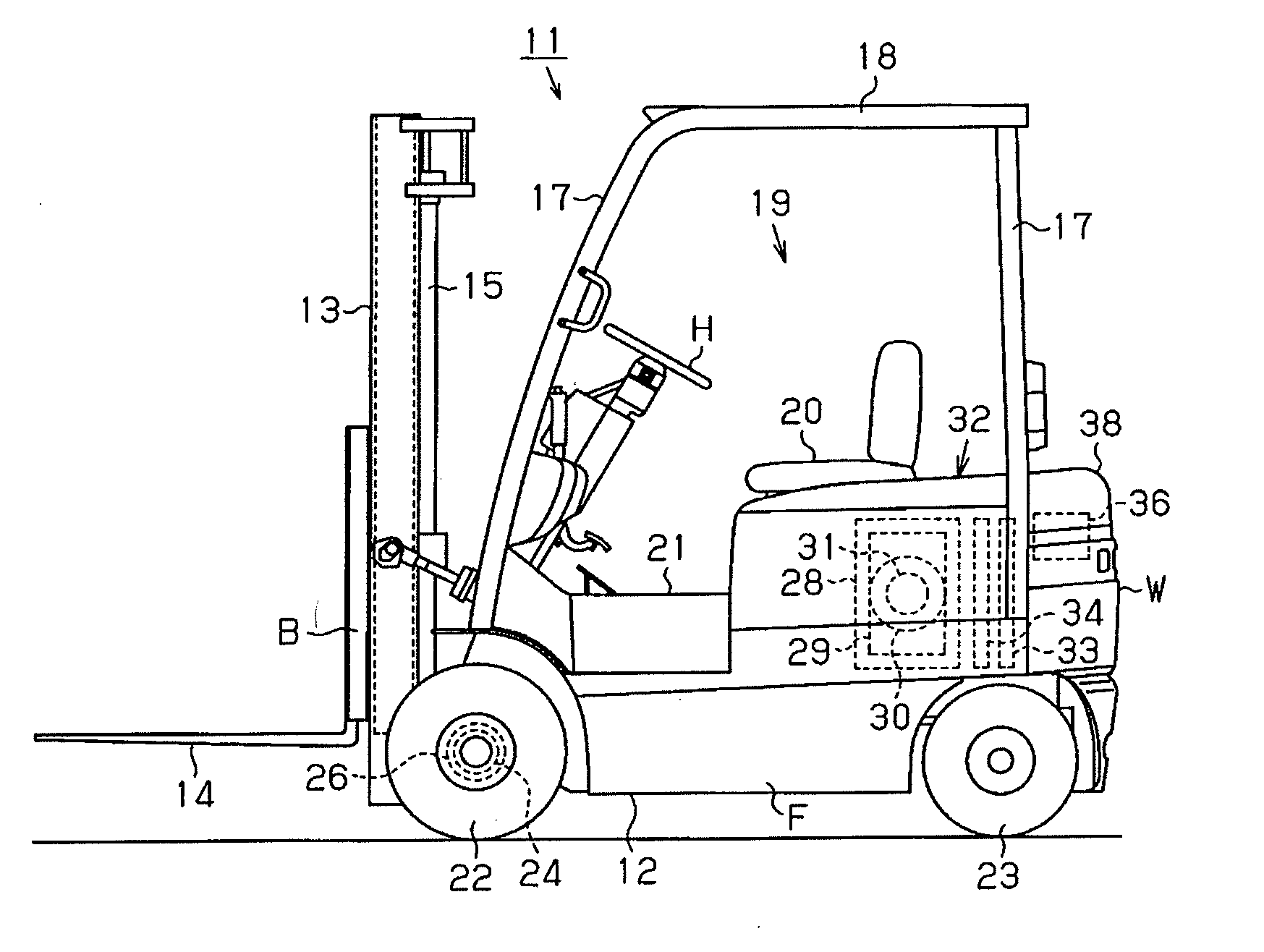

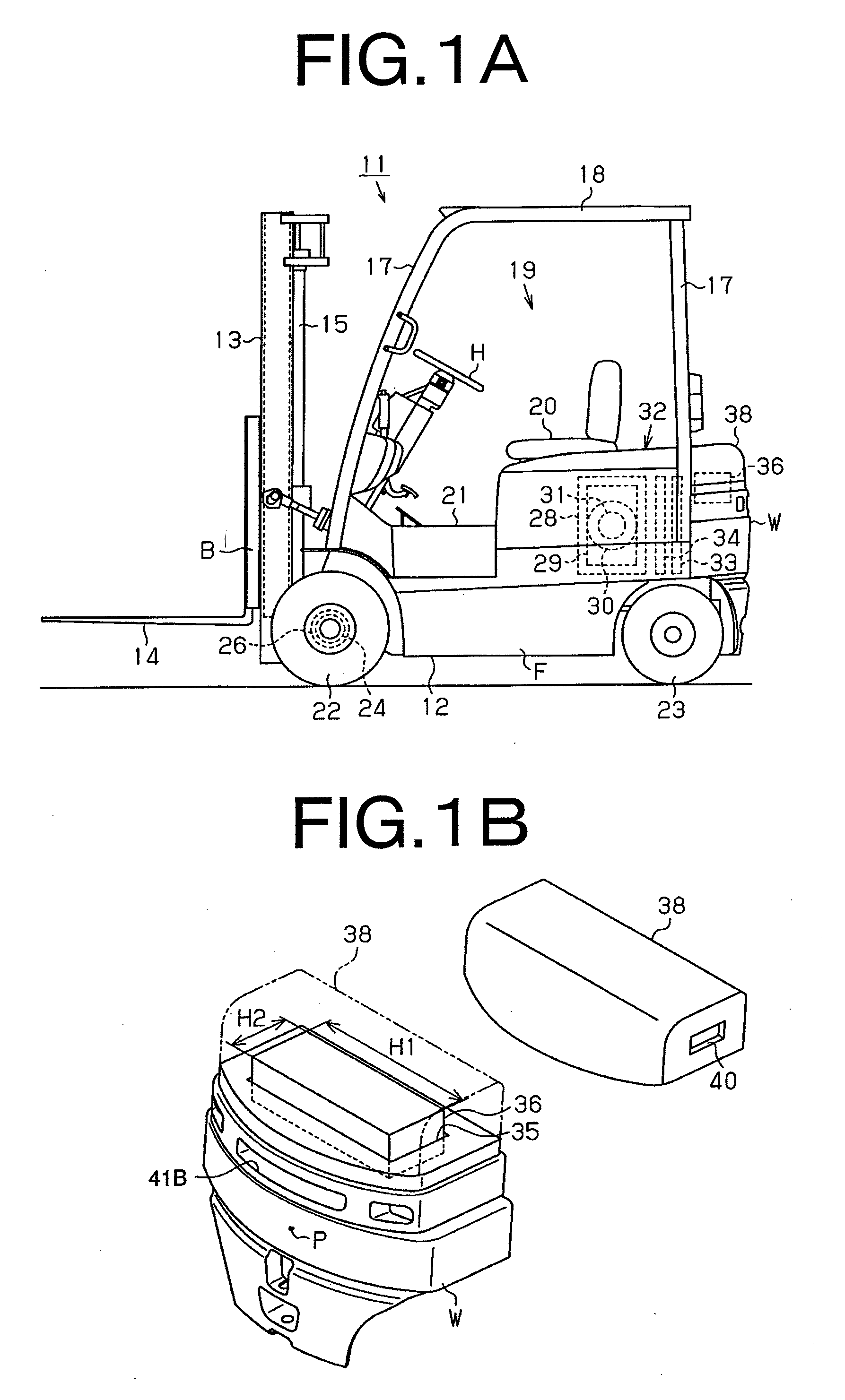

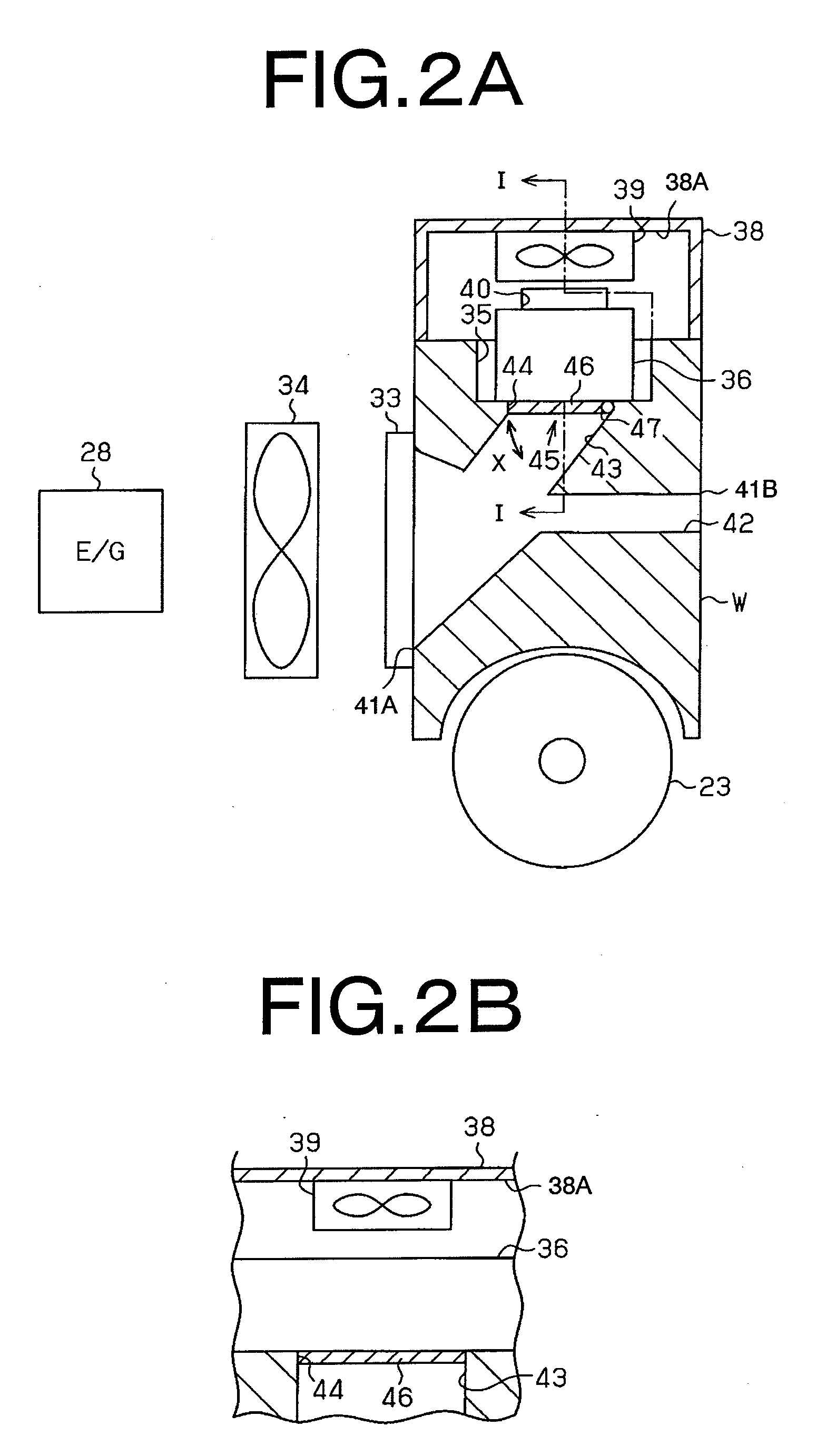

Hybrid industrial vehicle

InactiveUS20090283346A1Electric propulsion mountingPropulsion using engine-driven generatorsHybrid powerElectric motor

The present invention provides a hybrid industrial vehicle which prevents the battery from water splash.A hybrid industrial vehicle has a combination of an engine and a motor as a drive source for load handling or traveling, a battery as a power source for the motor and a counterweight. The battery is disposed on the counterweight and is located above the center of the counterweight as measured in the vertical direction between the highest and the lowest ends thereof.

Owner:TOYOTA IND CORP

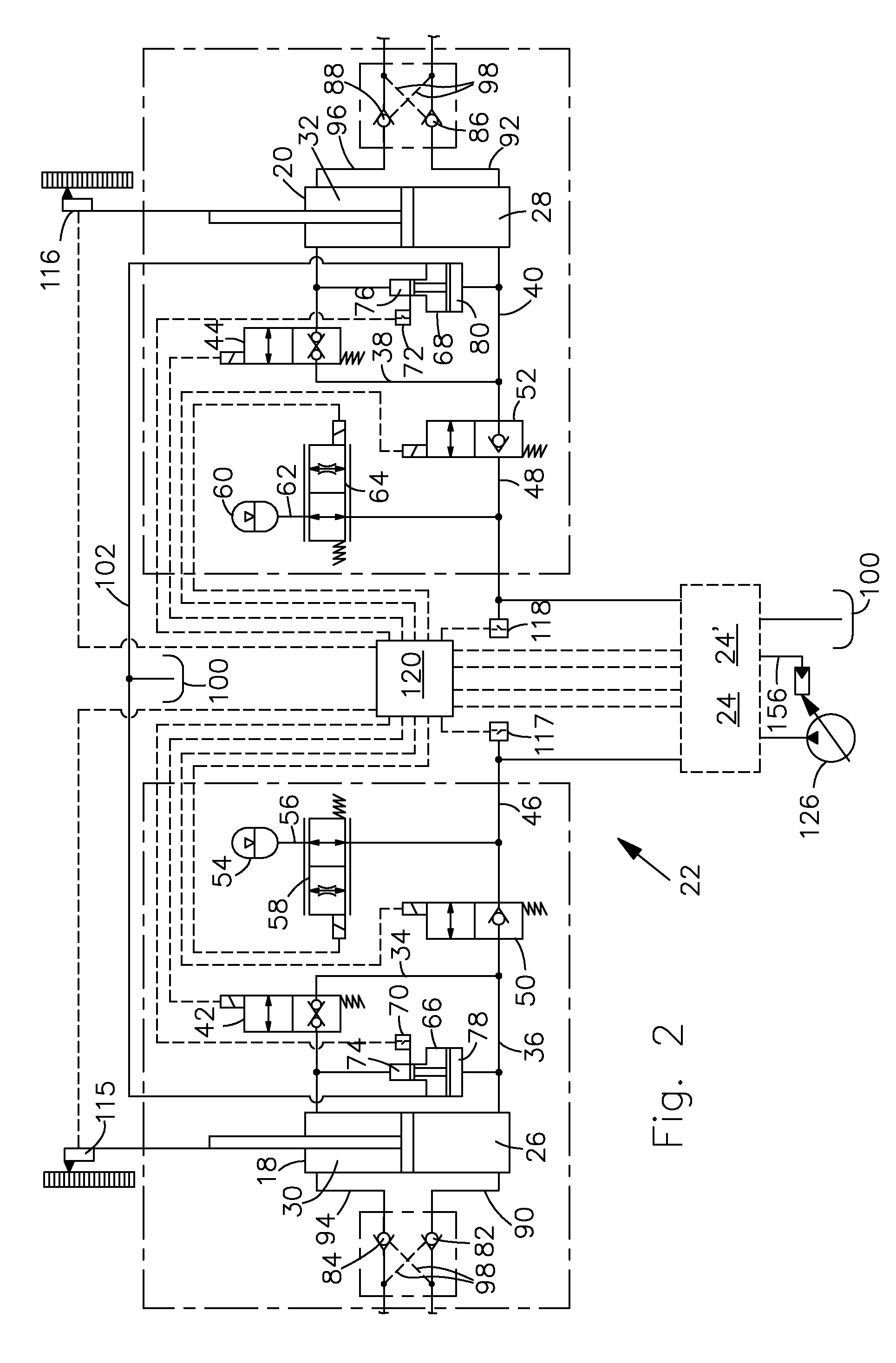

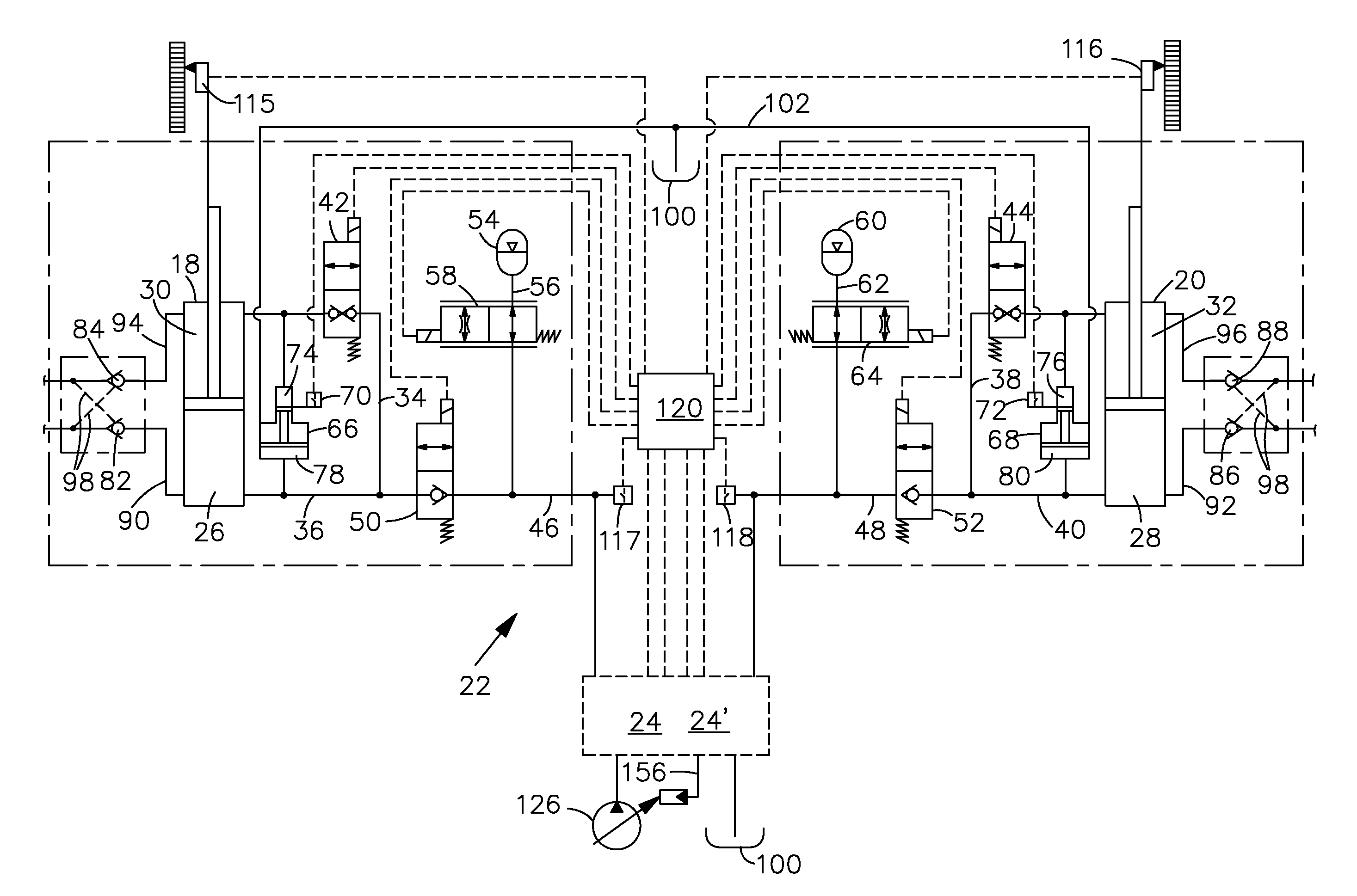

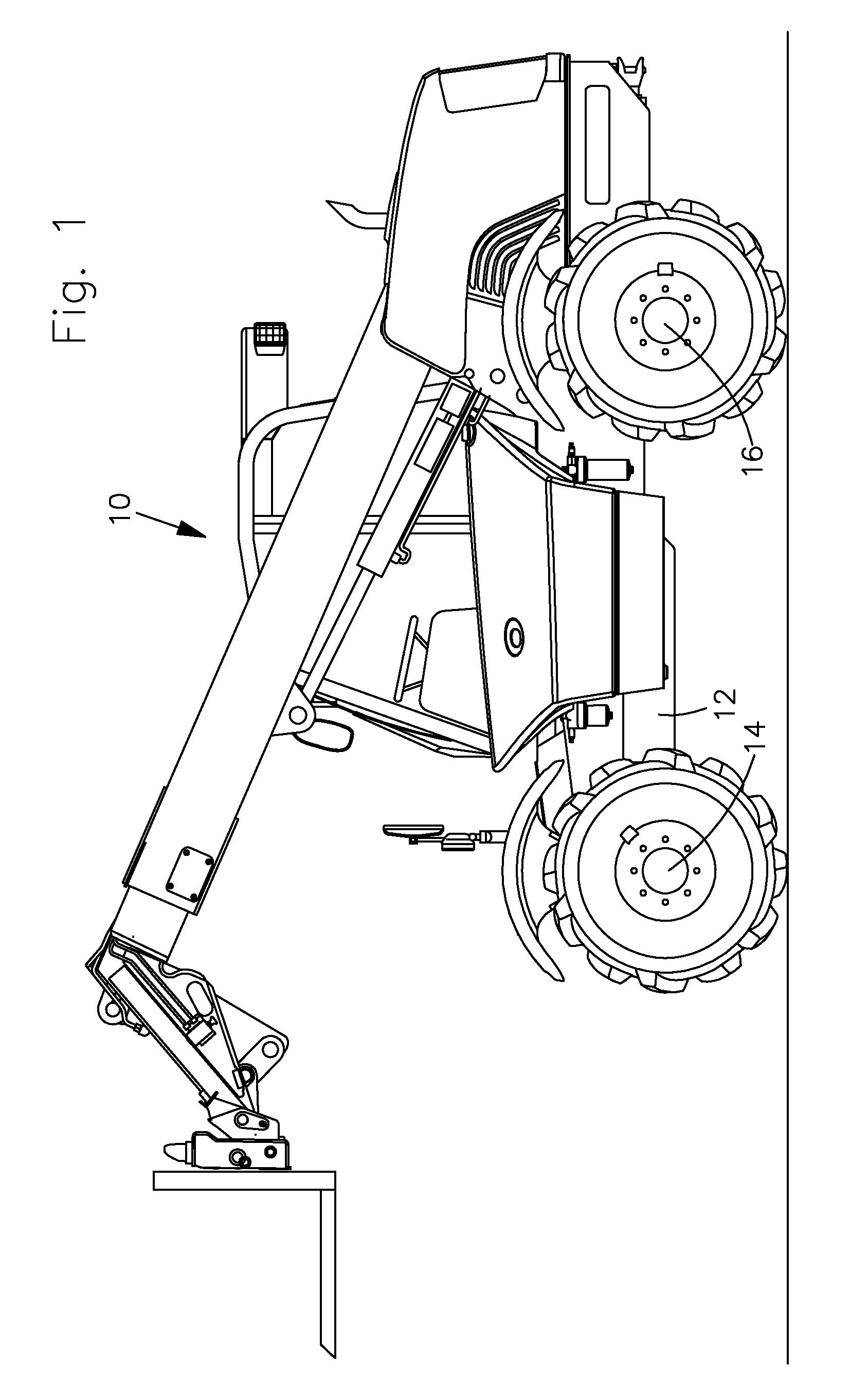

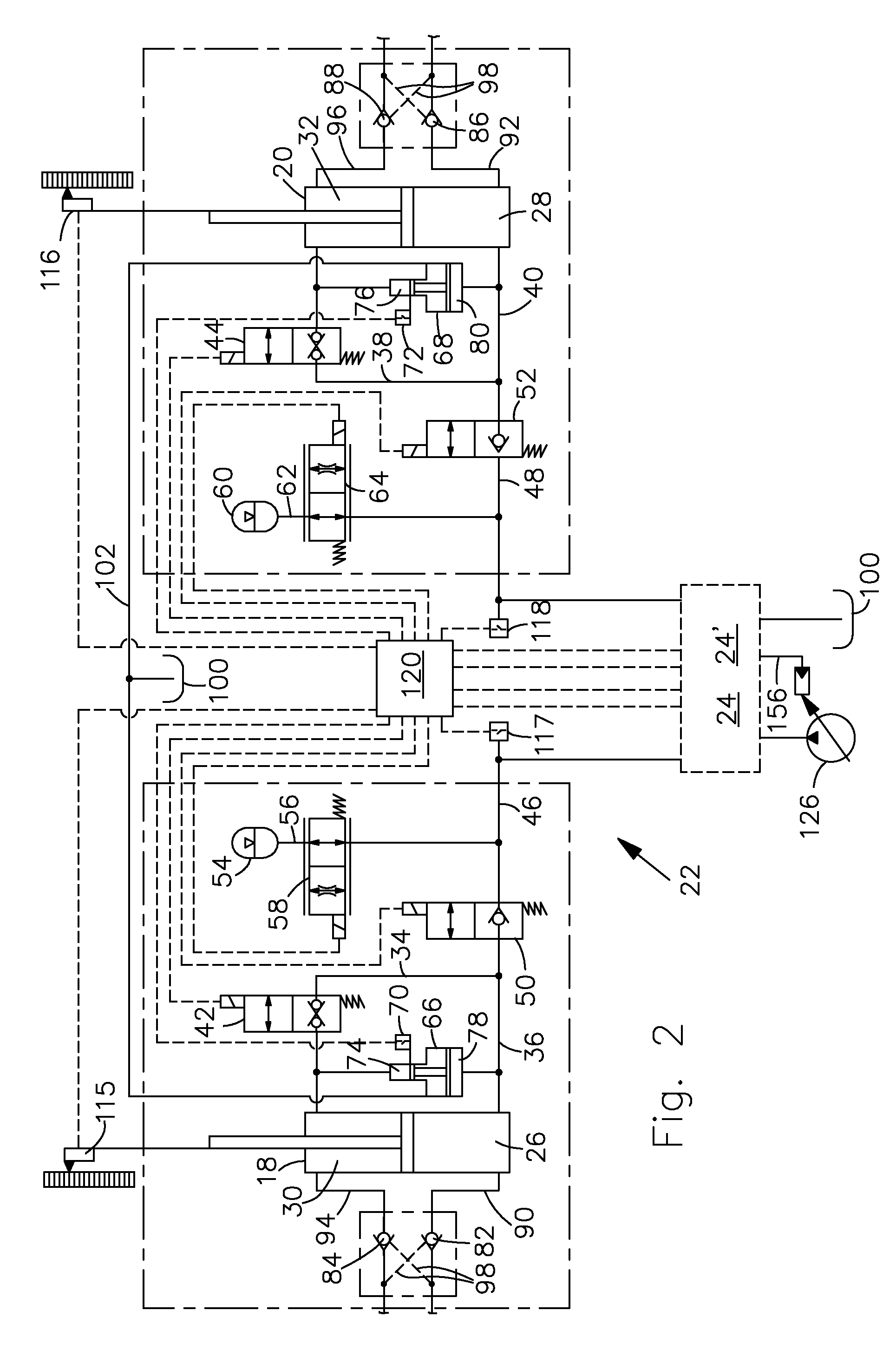

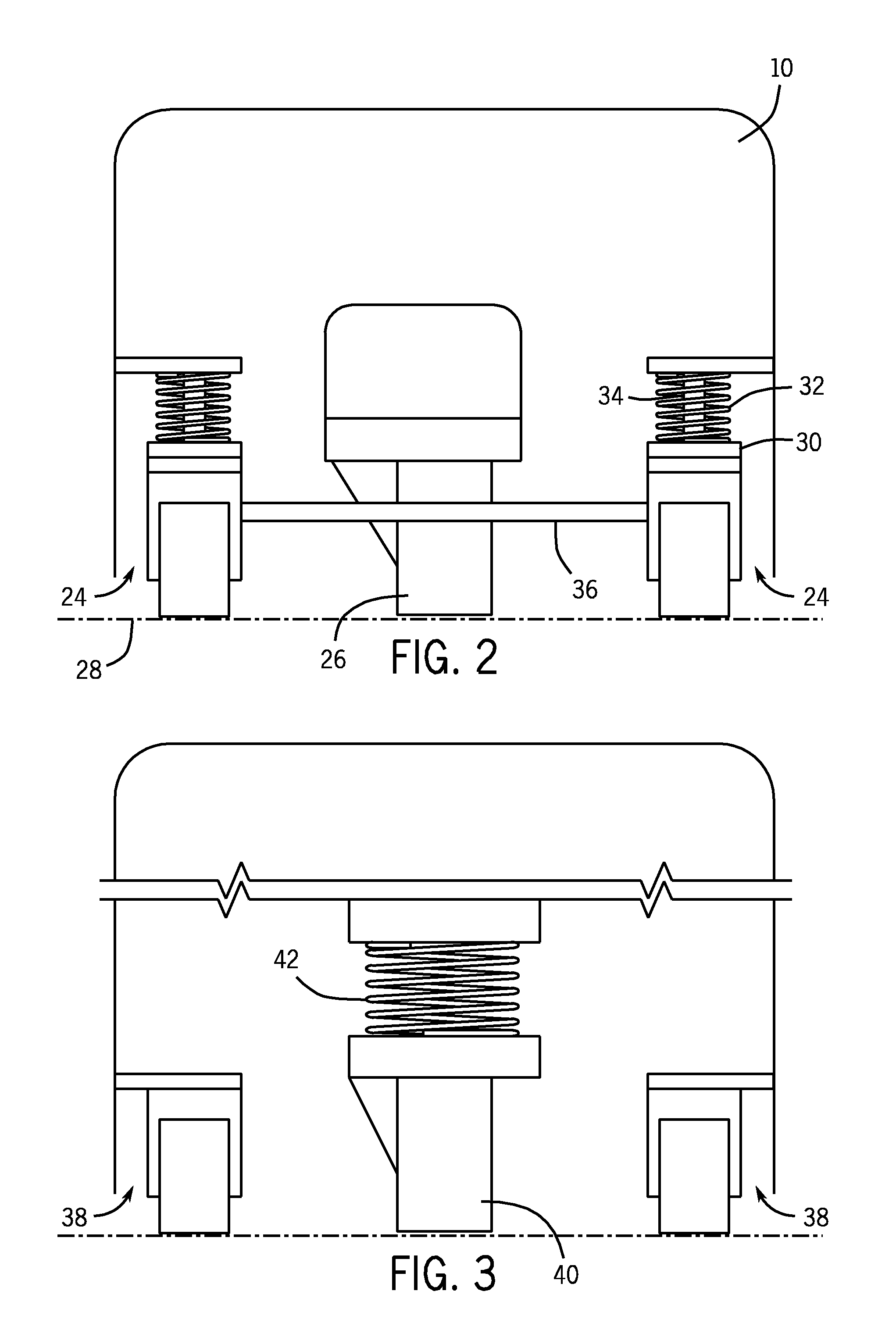

Suspension System

InactiveUS20080100017A1Reduce the impactProlong lifePedestrian/occupant safety arrangementVehicle fittings for liftingHydraulic cylinderLine tubing

A suspension system for an agricultural or construction industry vehicle is described. The suspension system comprises two hydraulic cylinders, which support a frame in relation to an axle of the vehicle, the hydraulic cylinders each having a piston-side chamber and a piston rod-side chamber and each of the chambers of the hydraulic cylinders being connectable to one another via connecting lines provided with a switch valve, a first supply line, which can be connected via a switch valve to the piston-side connecting line of the first hydraulic cylinder, a second supply line, which can be connected via a switch valve to the piston-side connecting line of the second hydraulic cylinder, a hydraulic accumulator, in each case connectable to the supply lines via proportionally adjustable orifices, a hydraulic source, a hydraulic tank, a control valve device, and an electronic control unit. In order to prevent the activation of a suspension state in critical vehicle states, means for the detection and compensation of load states of the vehicle are provided in the suspension system.

Owner:DEERE & CO

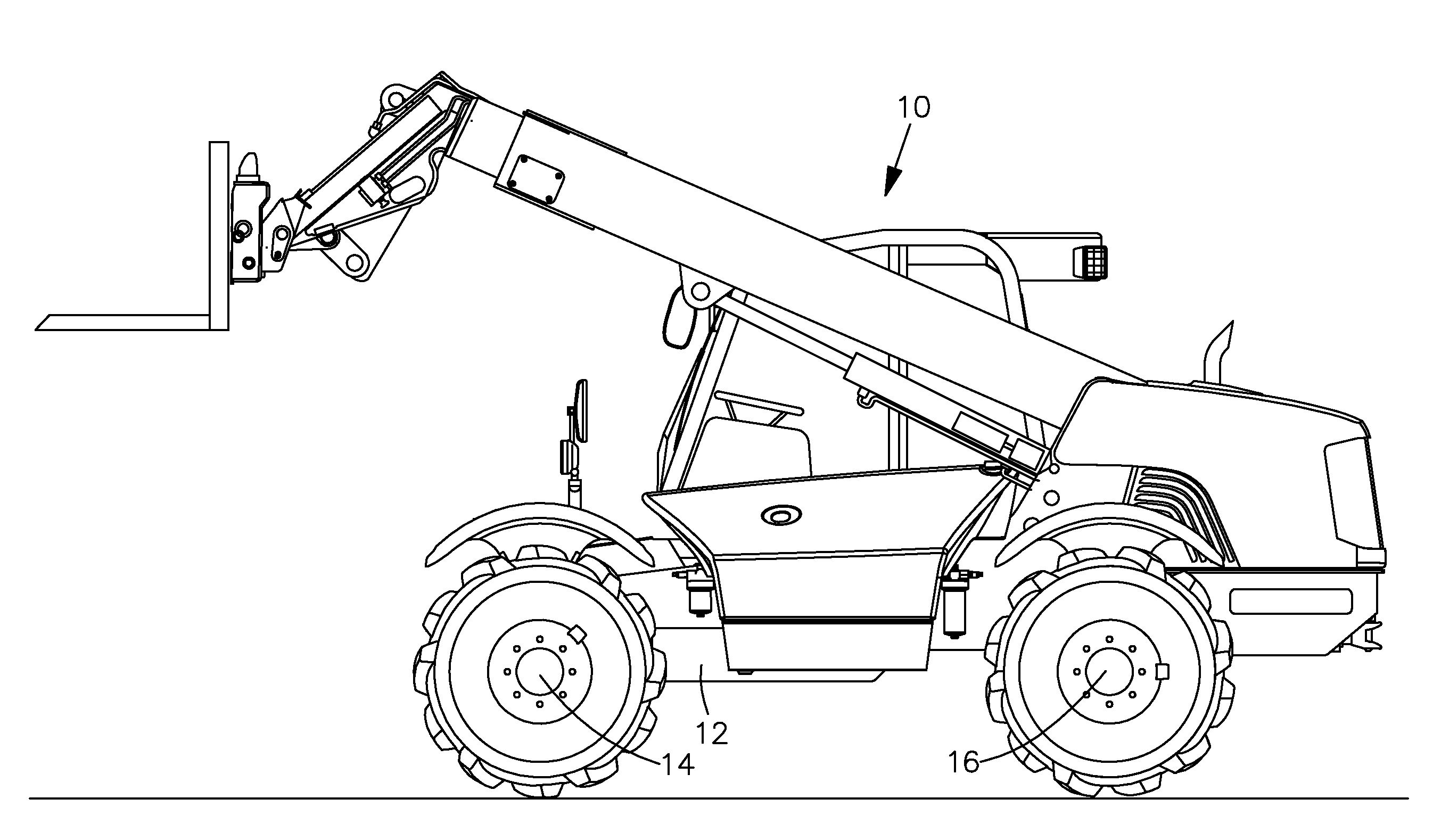

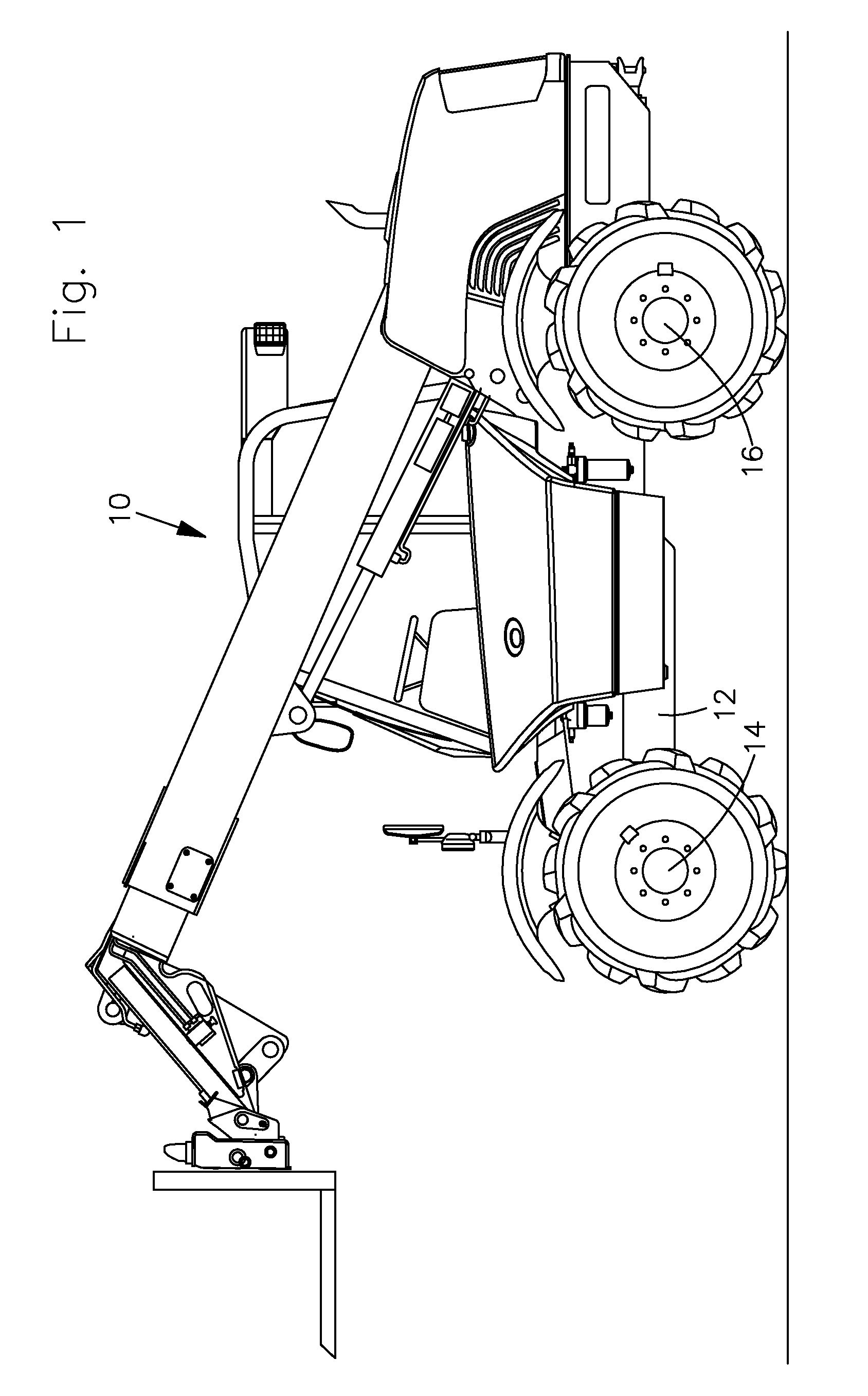

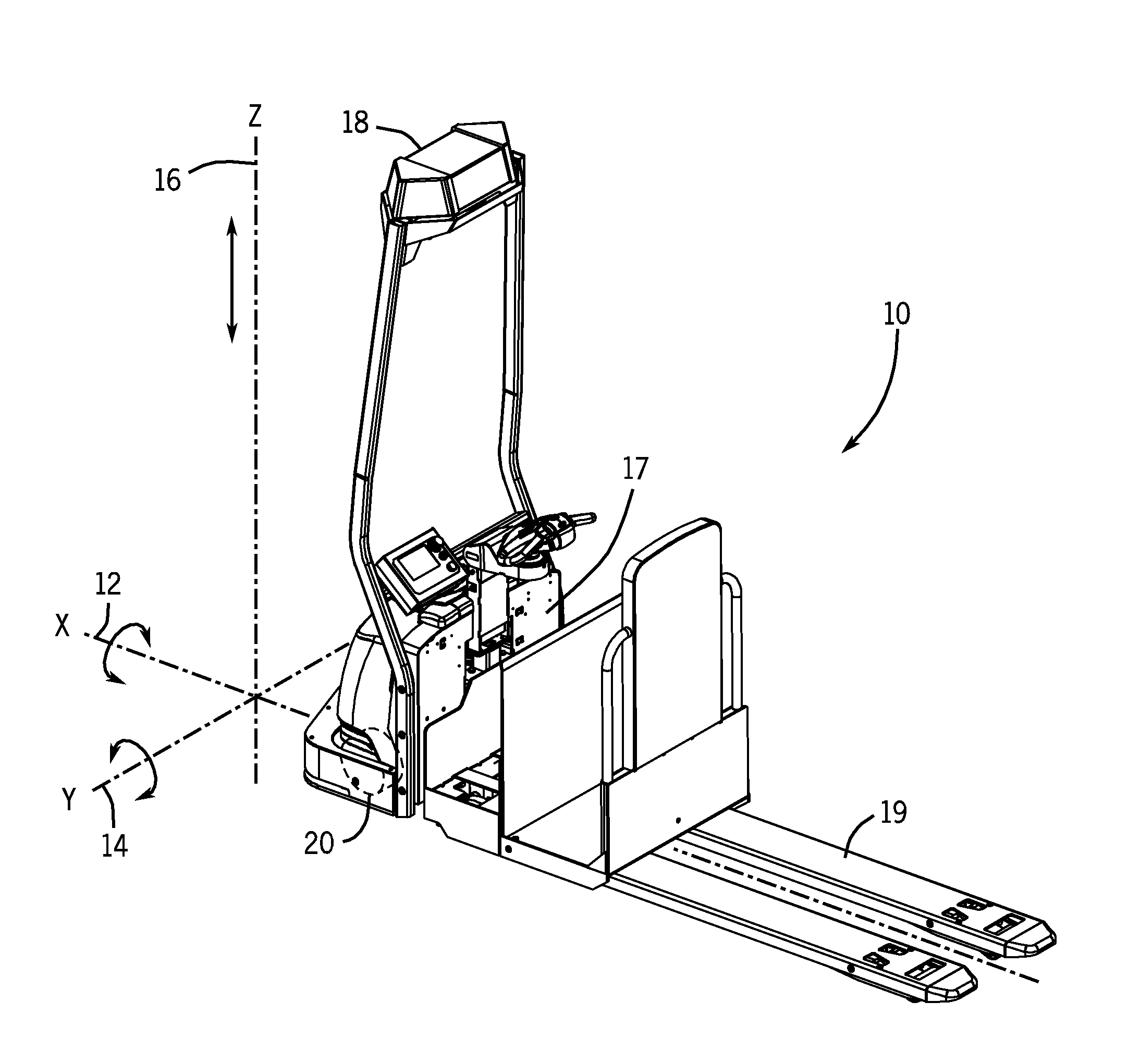

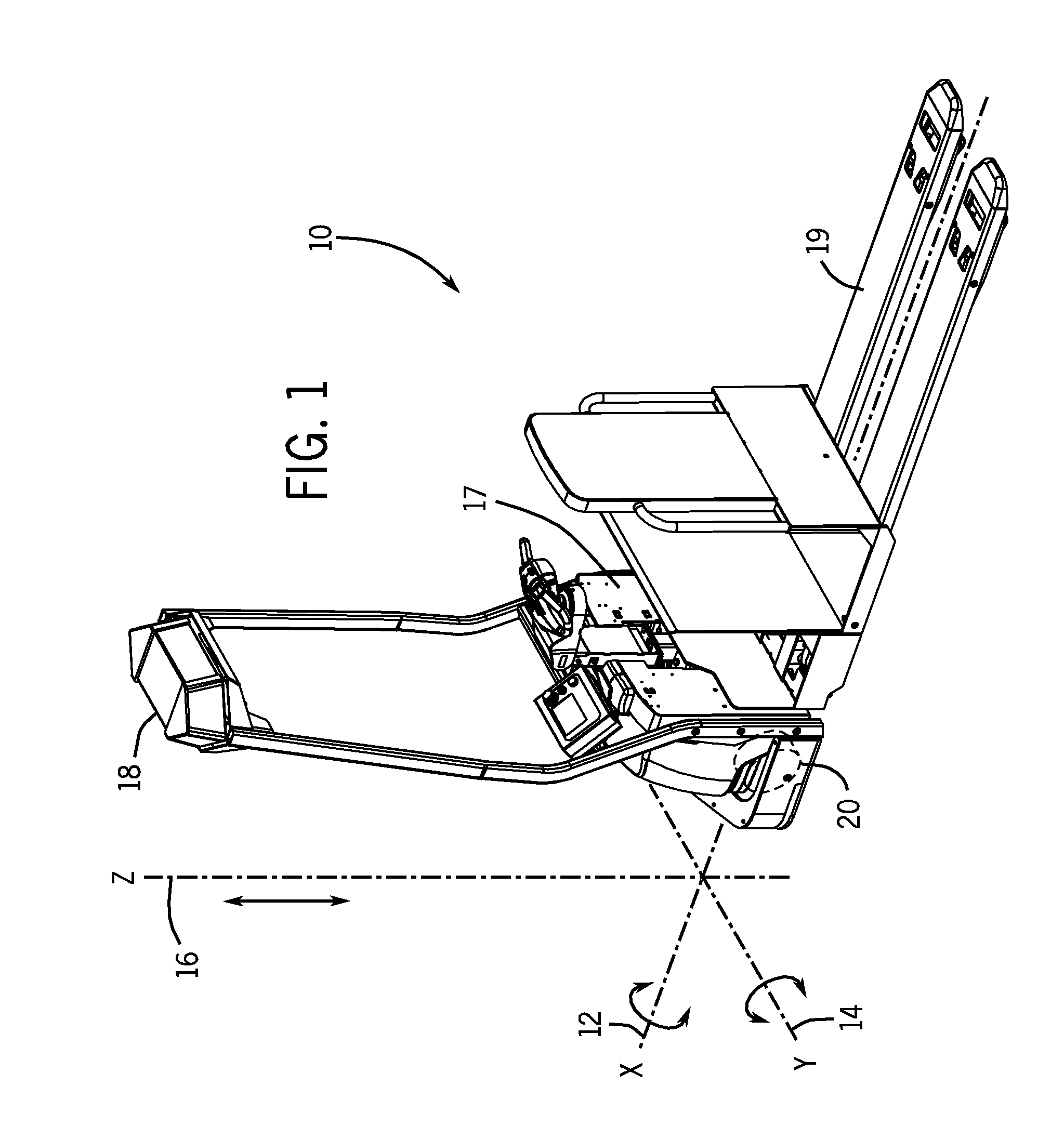

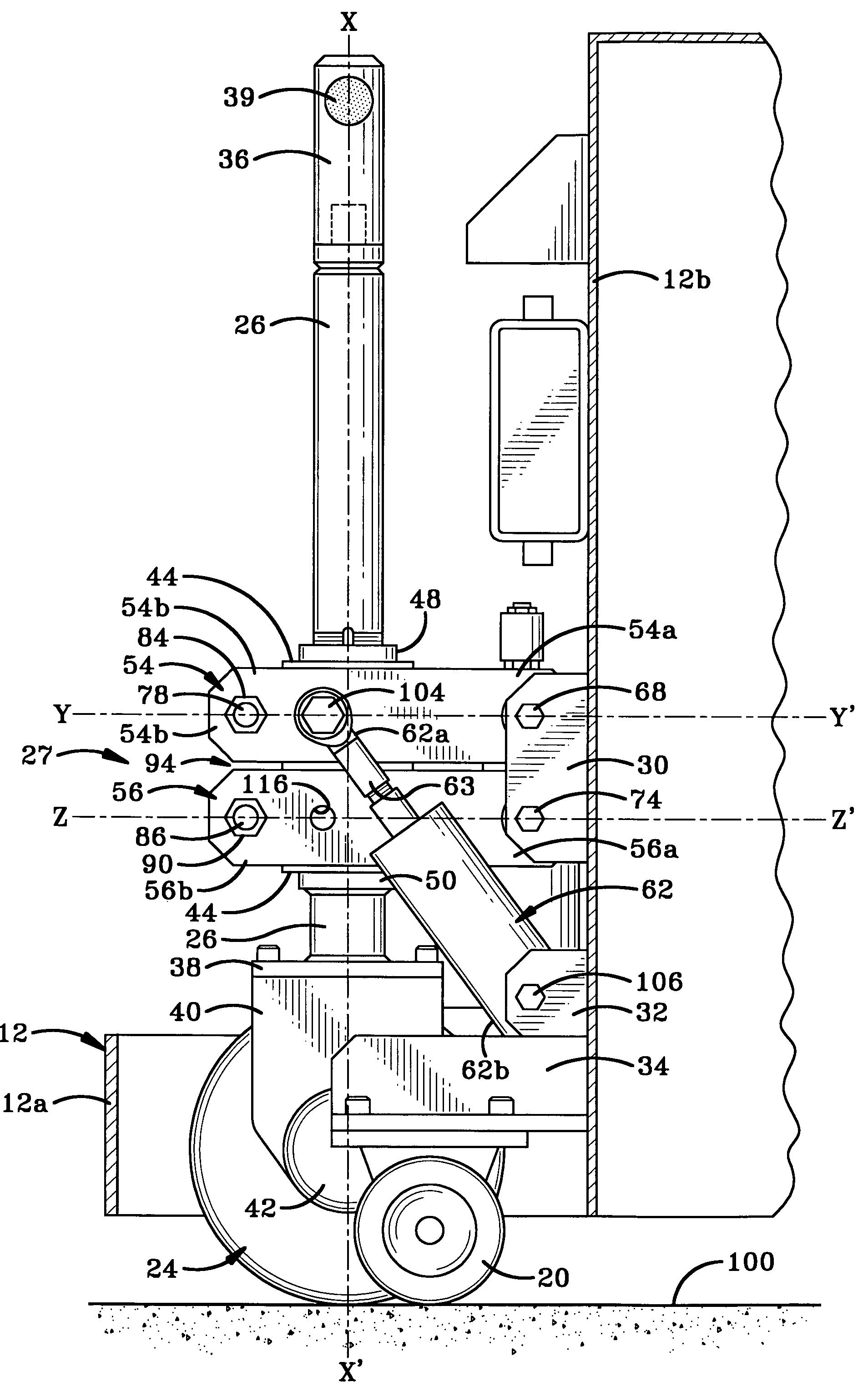

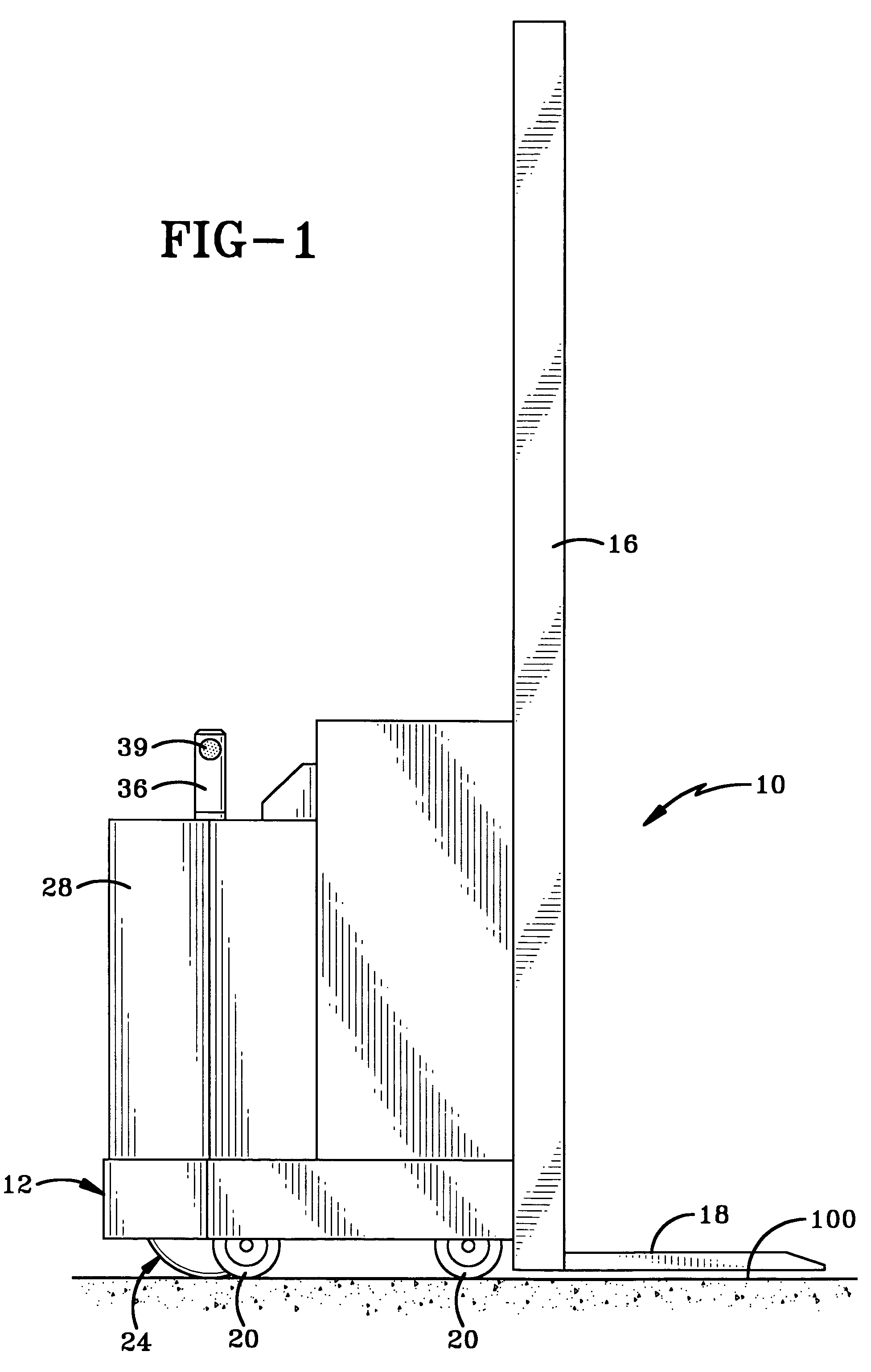

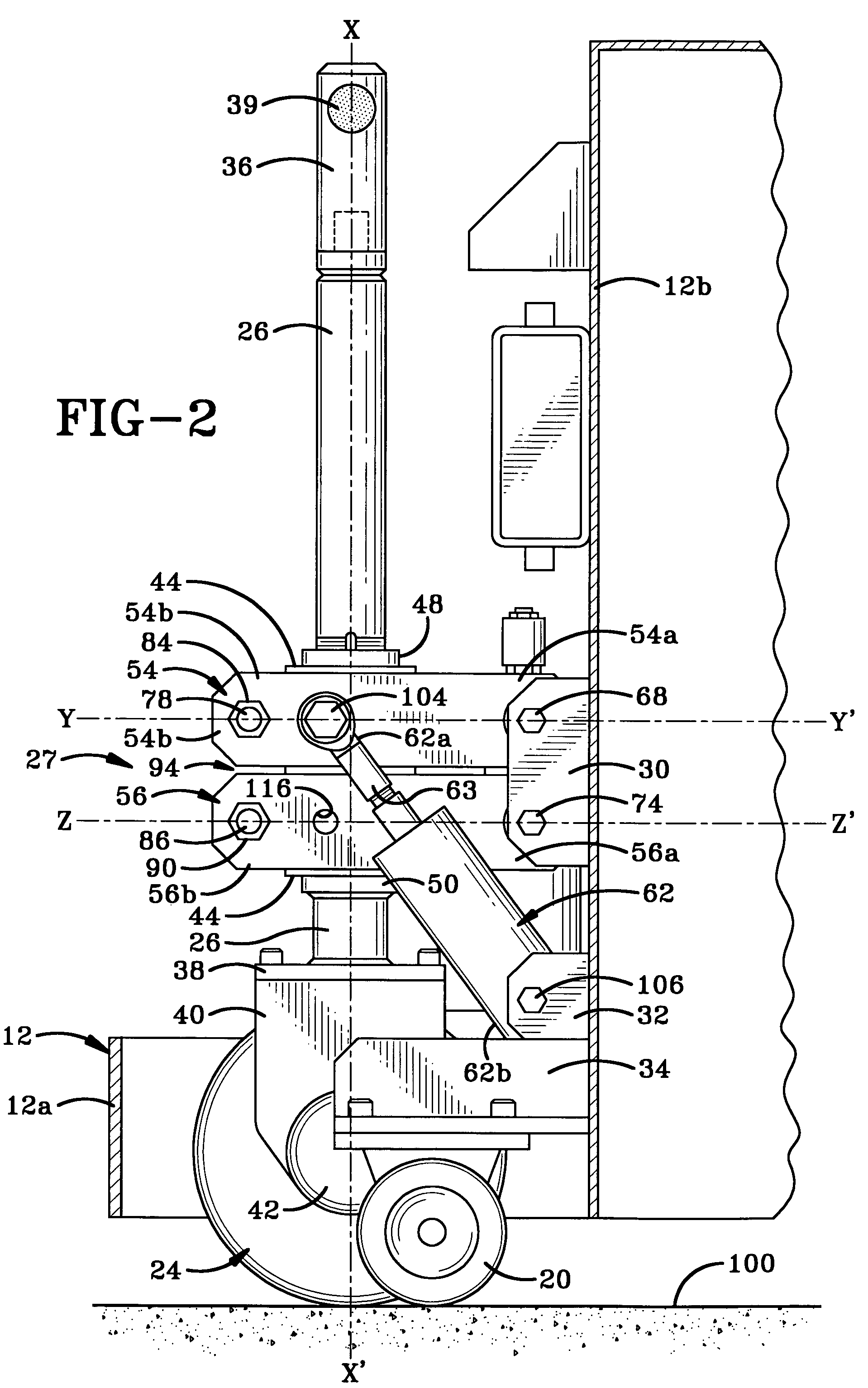

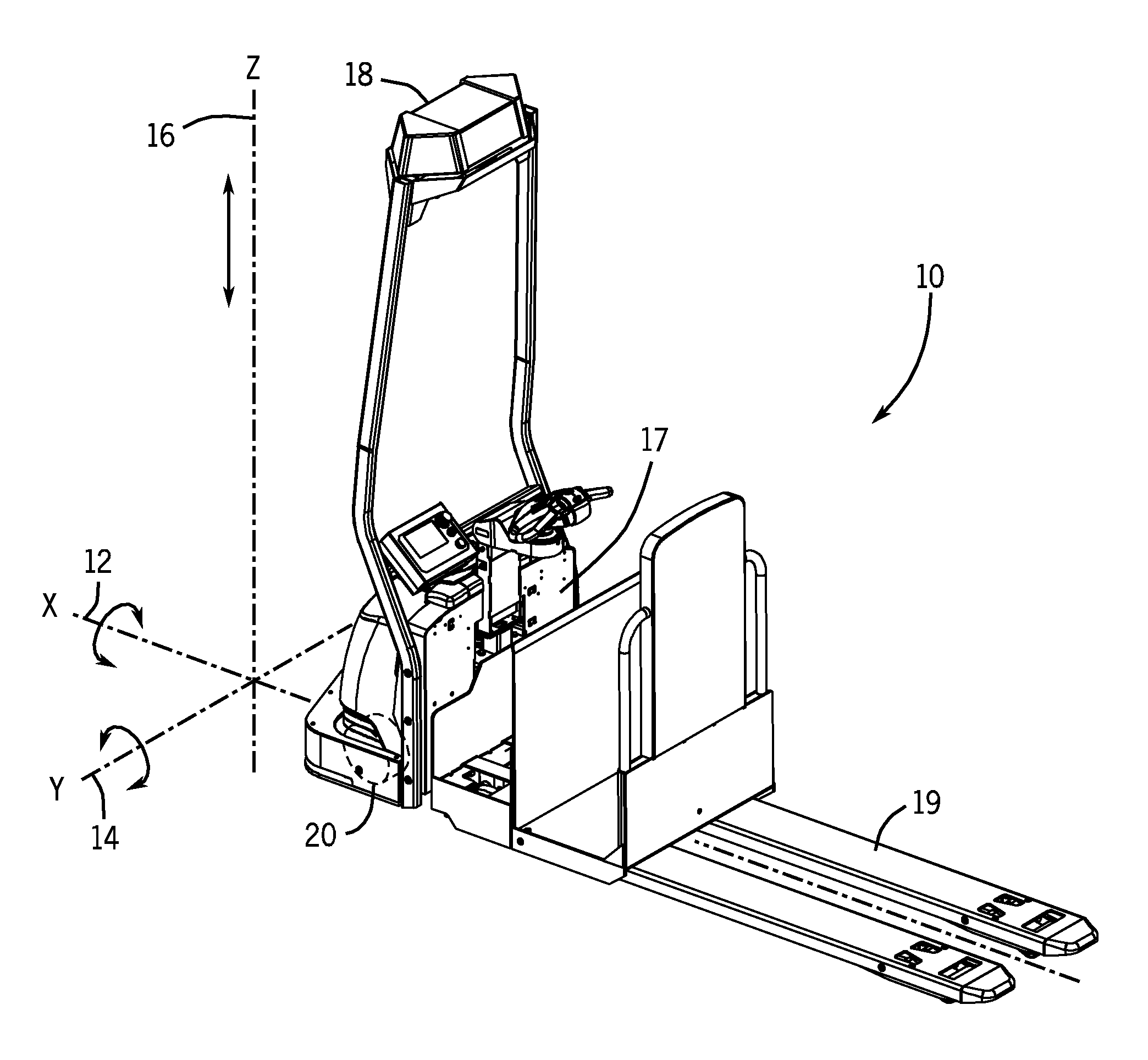

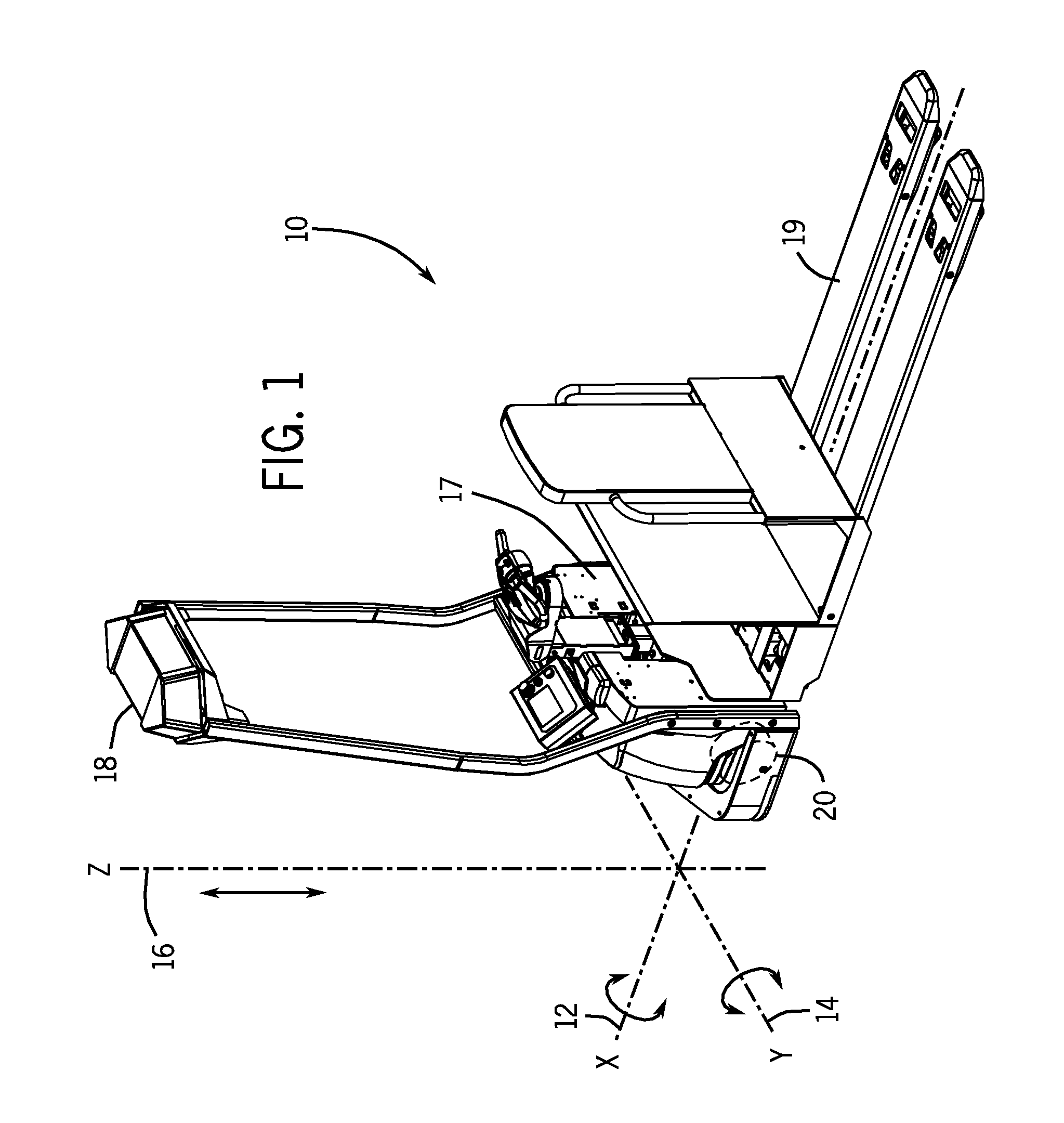

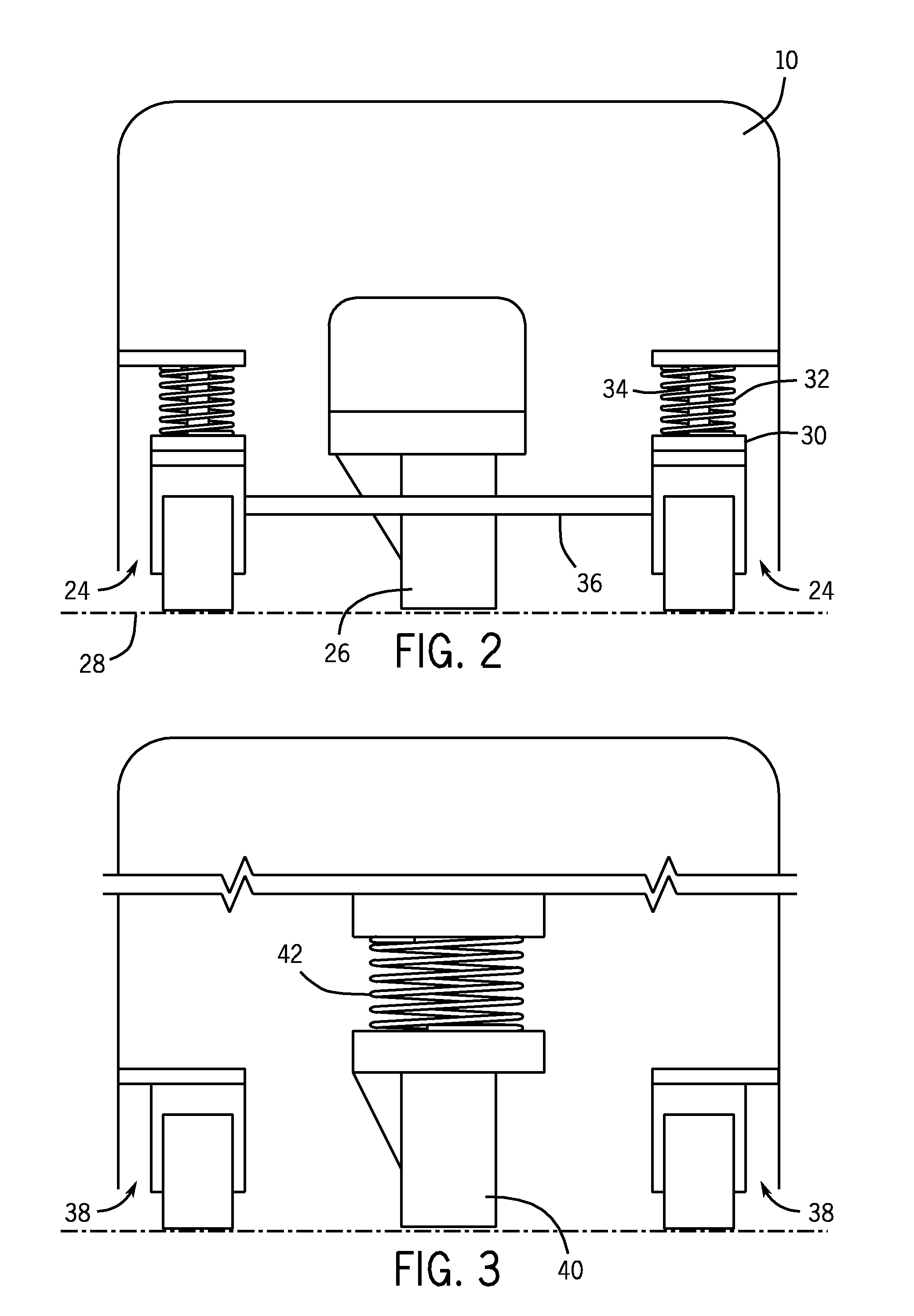

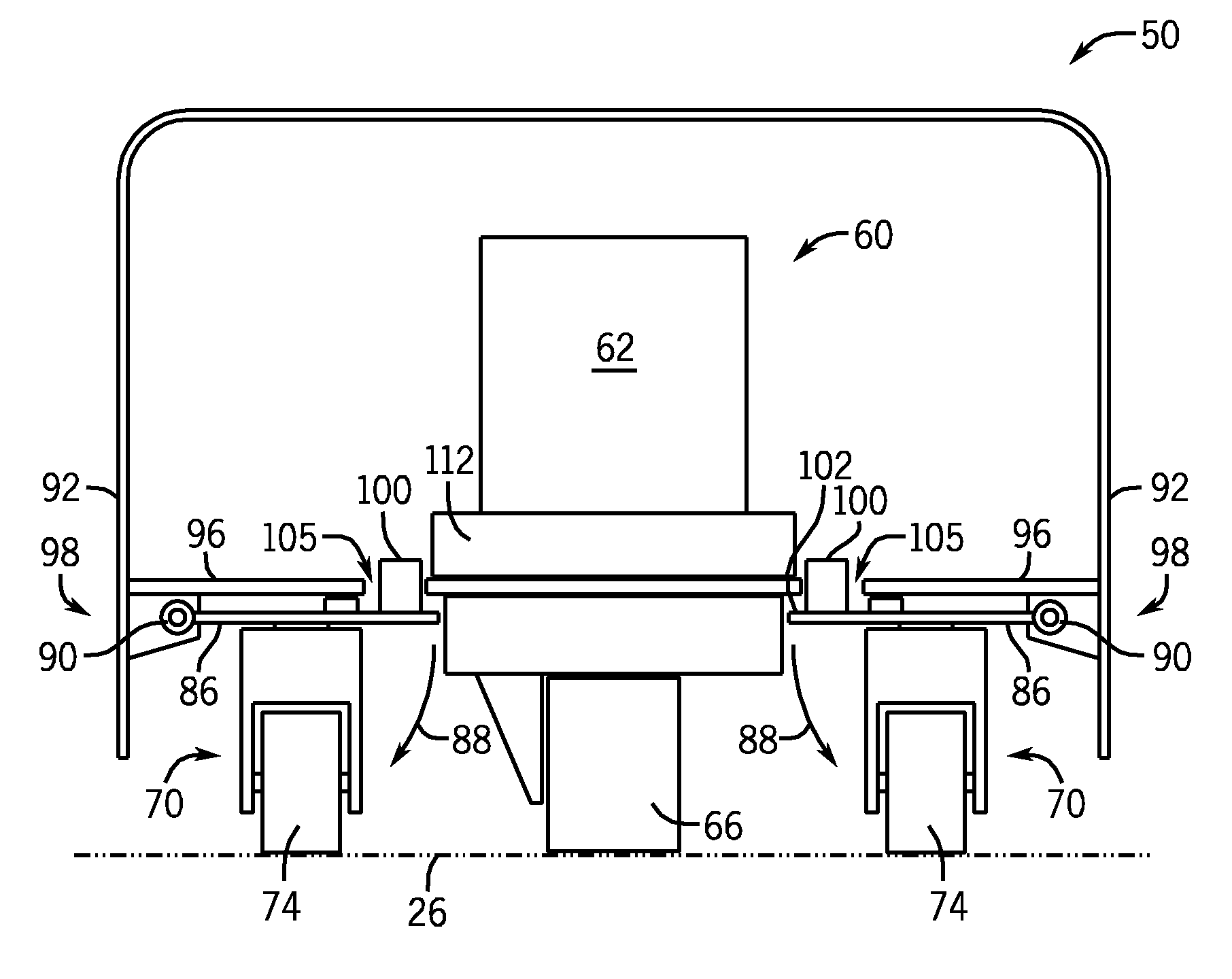

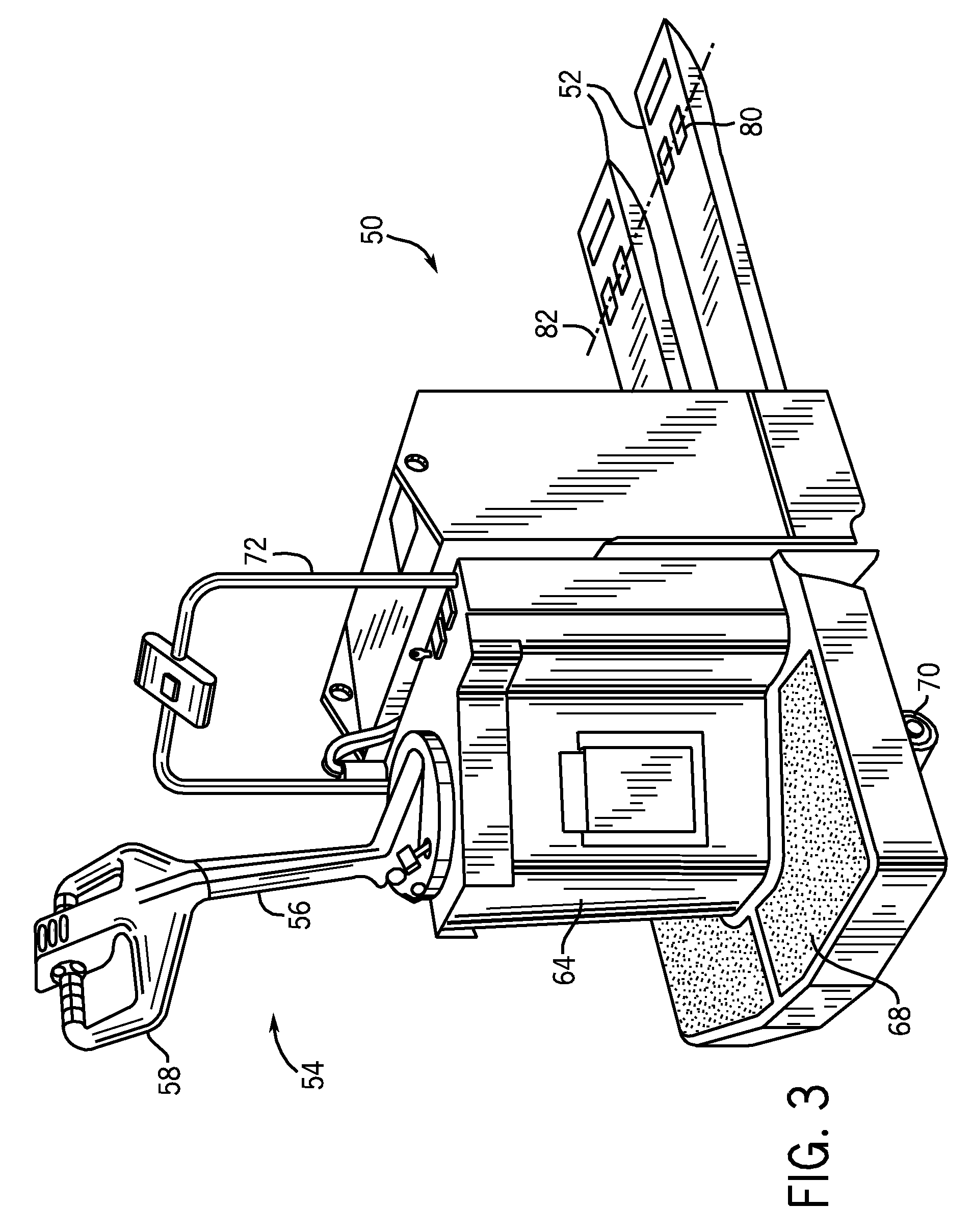

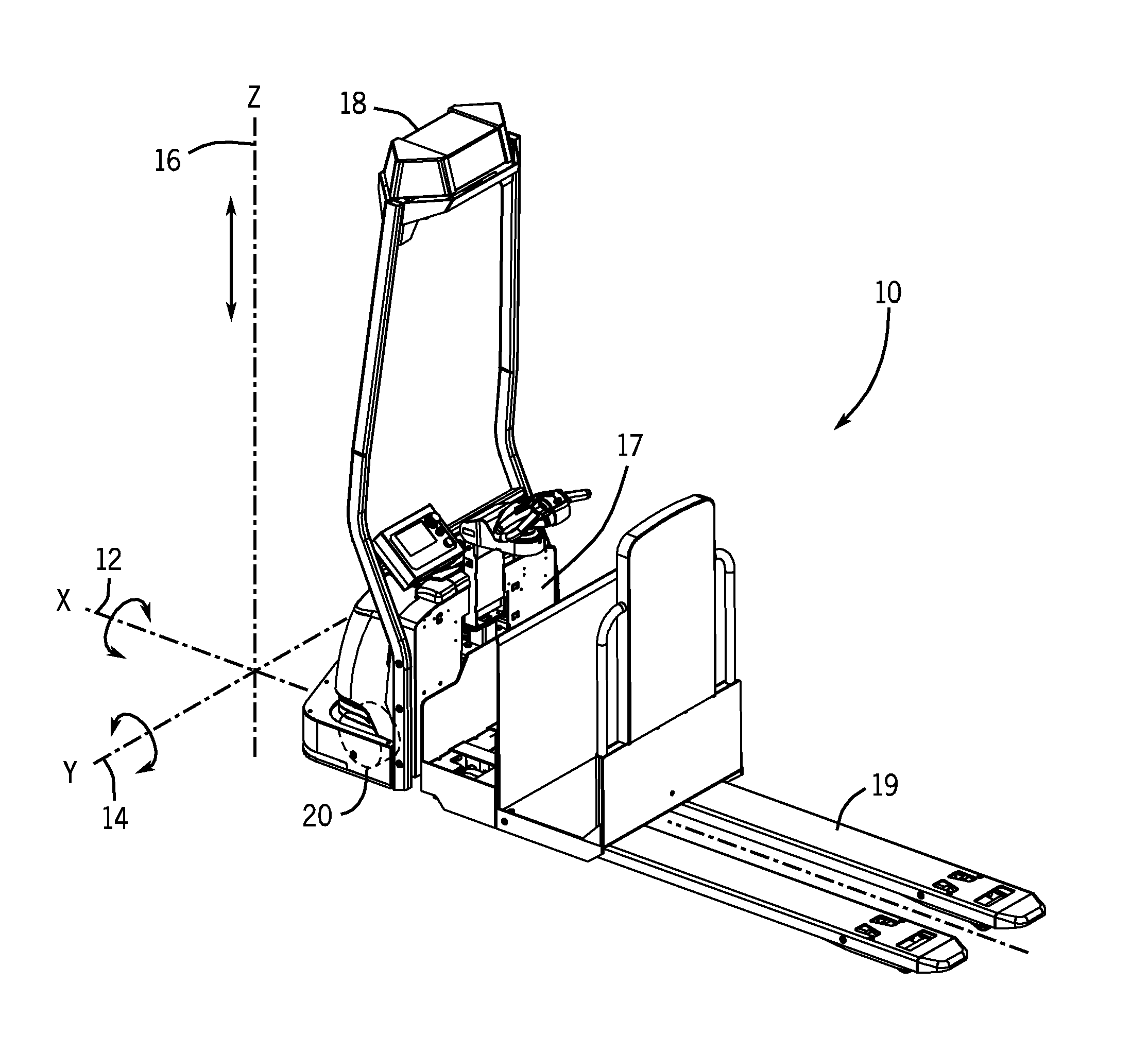

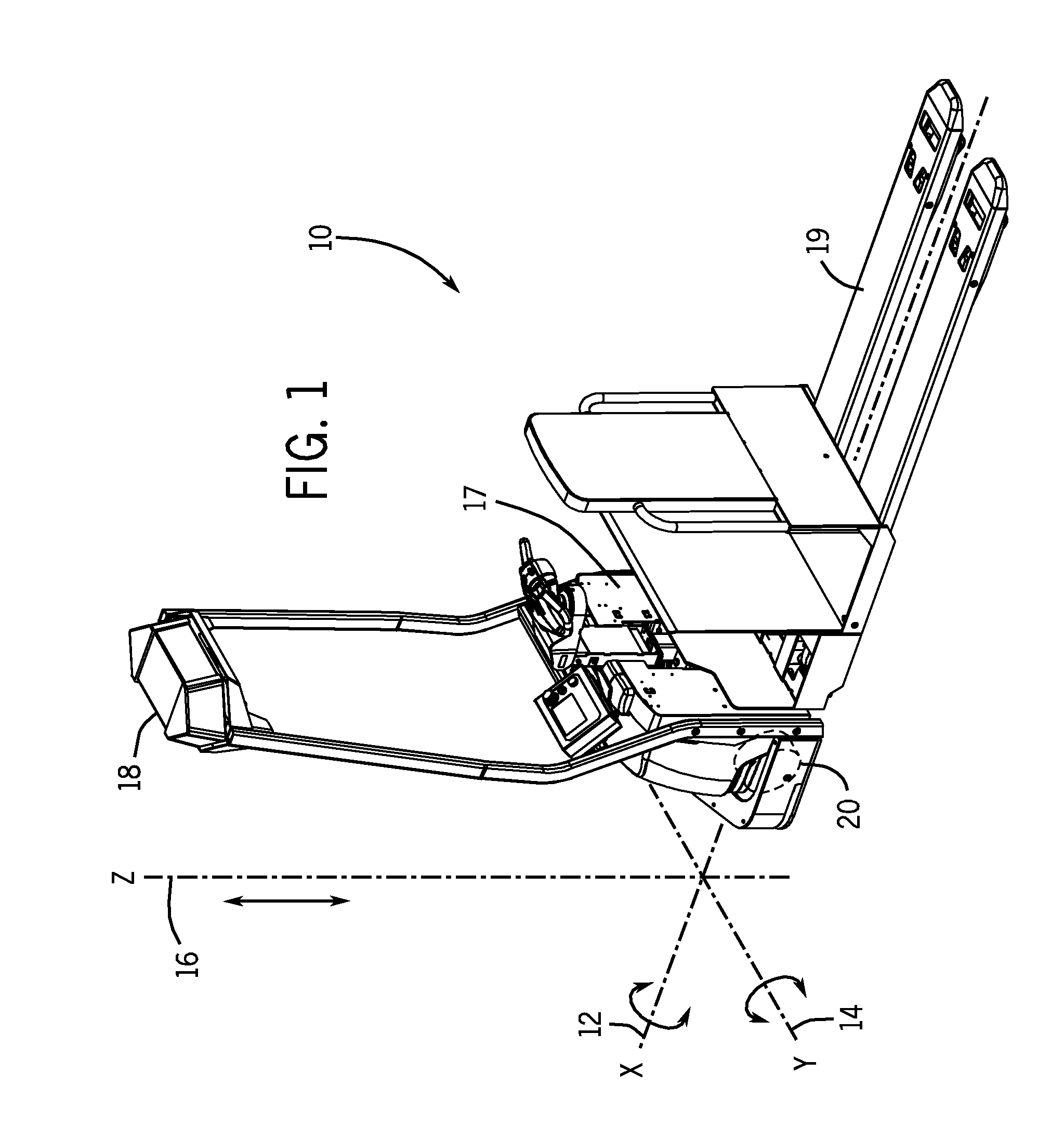

Dynamic stability control systems and methods for industrial lift trucks

ActiveUS8731785B2Reduce and eliminate motionOvercomes drawbackAnalogue computers for trafficSoil-shifting machines/dredgersVibration controlControl system

A lift truck includes systems and methods for improved stability control. Stability control features reduce or eliminate motion of the truck in one or more of the X-axis, Y-axis, and Z-axis. Some embodiments may include, alone or in combination with the stability control, vibration control to further stabilize the motion of the truck.

Owner:RAYMOND LTD

Variable ride control

A skid steer vehicle has a chassis with four drive wheels suspended from the chassis that are damped by four damping cylinders. An electronic controller varies the damping of the cylinders in an automatic mode, based on certain operational parameters of the vehicle, and in a manual mode in response to operator selection of a desired degree of suspension damping.

Owner:BLUE LEAF I P INC

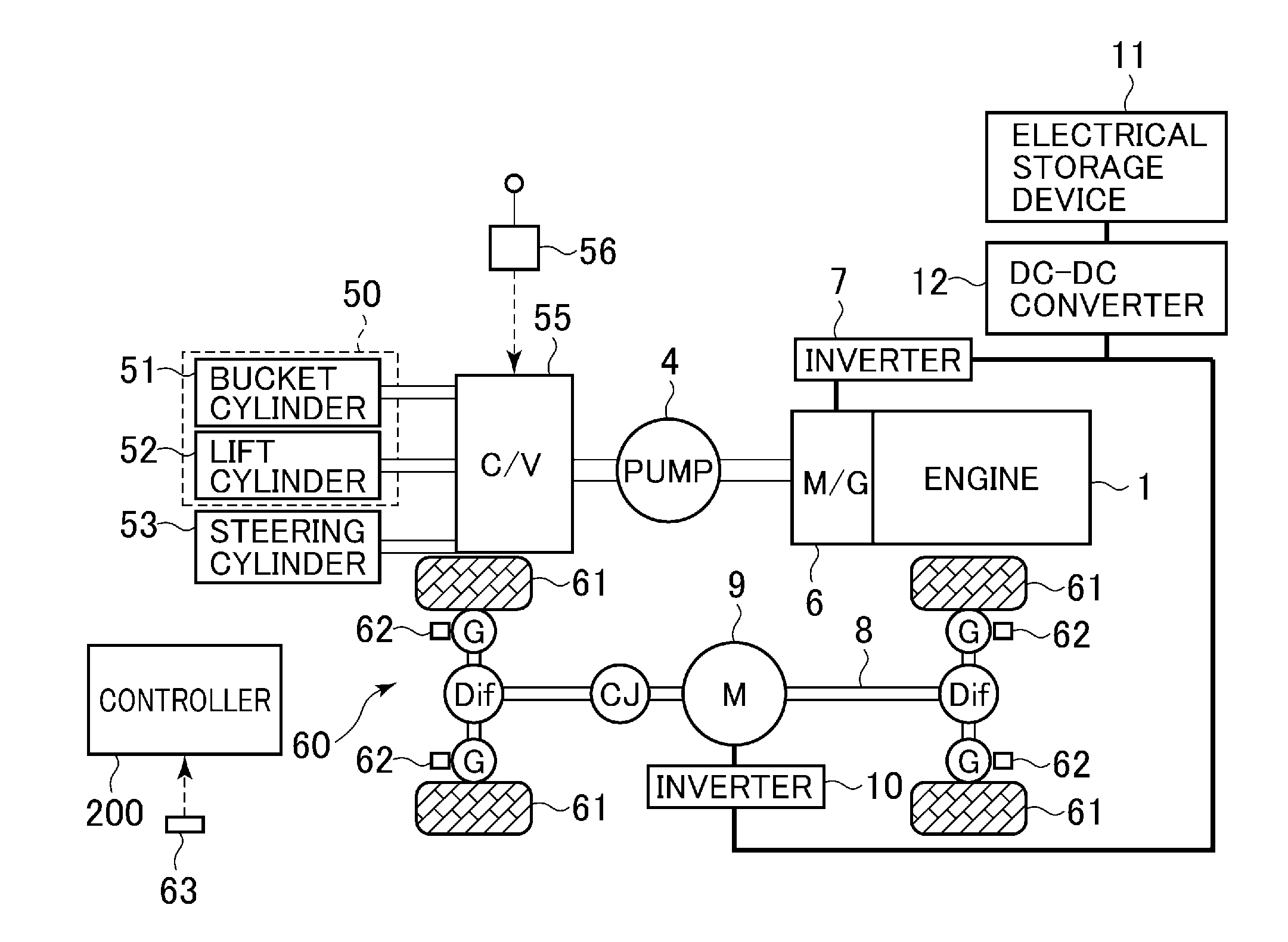

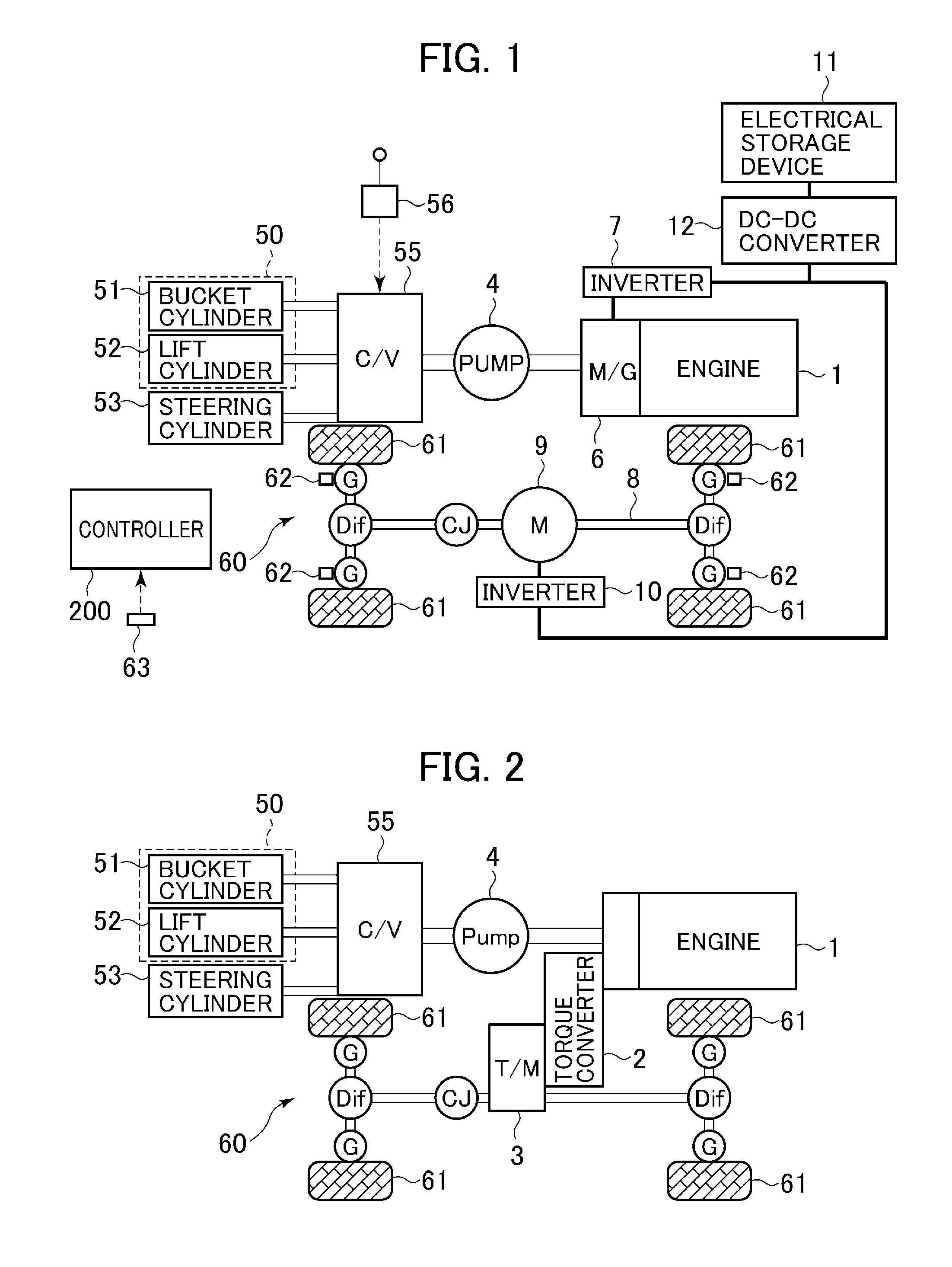

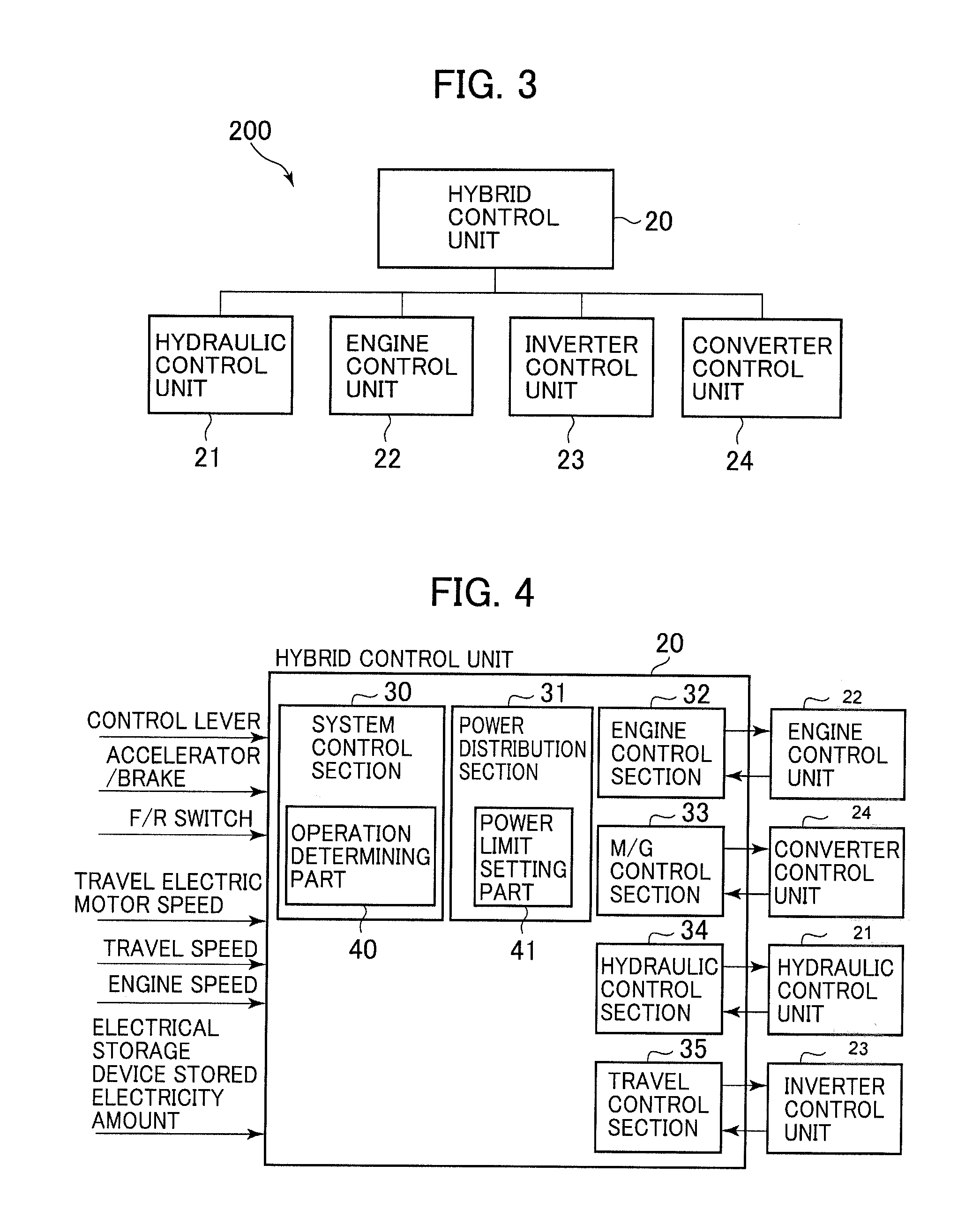

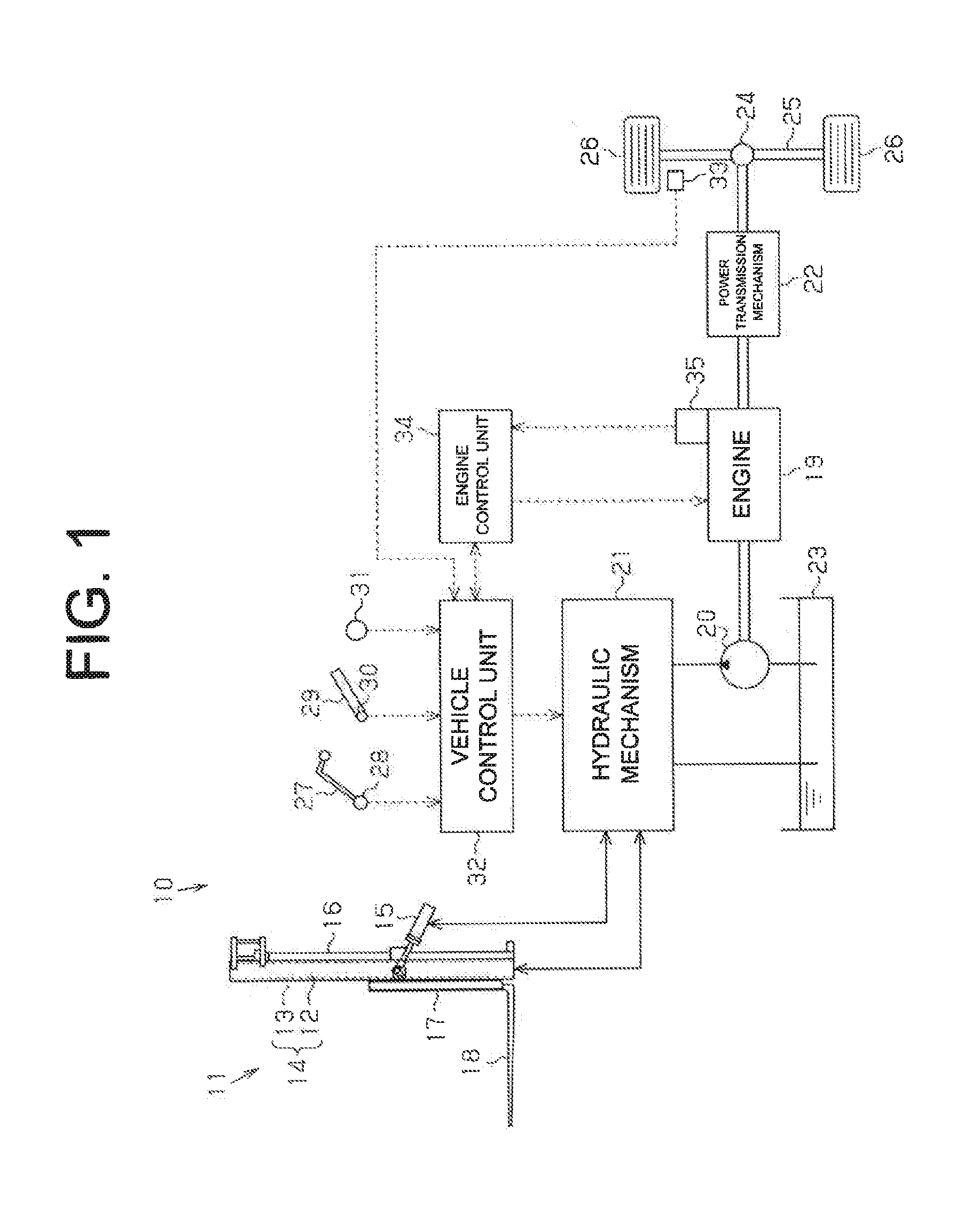

Wheel loader

ActiveUS20130317684A1Improve working efficiencyHybrid vehiclesDigital data processing detailsDrive wheelHydraulic pump

A hybrid wheel loader is provided, the hybrid wheel loader achieving high work efficiency even with a short supply of power to be output relative to a vehicle power requirement.The hybrid wheel loader includes a motor generator 6 connected to an engine (1), a hydraulic pump (4) connected to the motor generator, a hydraulic actuator (51, 52, 53) driven by hydraulic oil supplied from the hydraulic pump, a travel electric motor (9) for driving wheels (61), and an electrical storage device (11) connected to each of the motor generator and the electrical storage device via respective inverters (7, 10). When a total requirement power value is greater than a hybrid output upper limit value, either one of a hydraulic requirement power value Pf and a travel requirement power value Prun is limited according to an operation of the wheel loader to thereby set the total requirement power value to a value equal to, or less than, the hybrid output upper limit value.

Owner:NIHON KENKI CO LTD

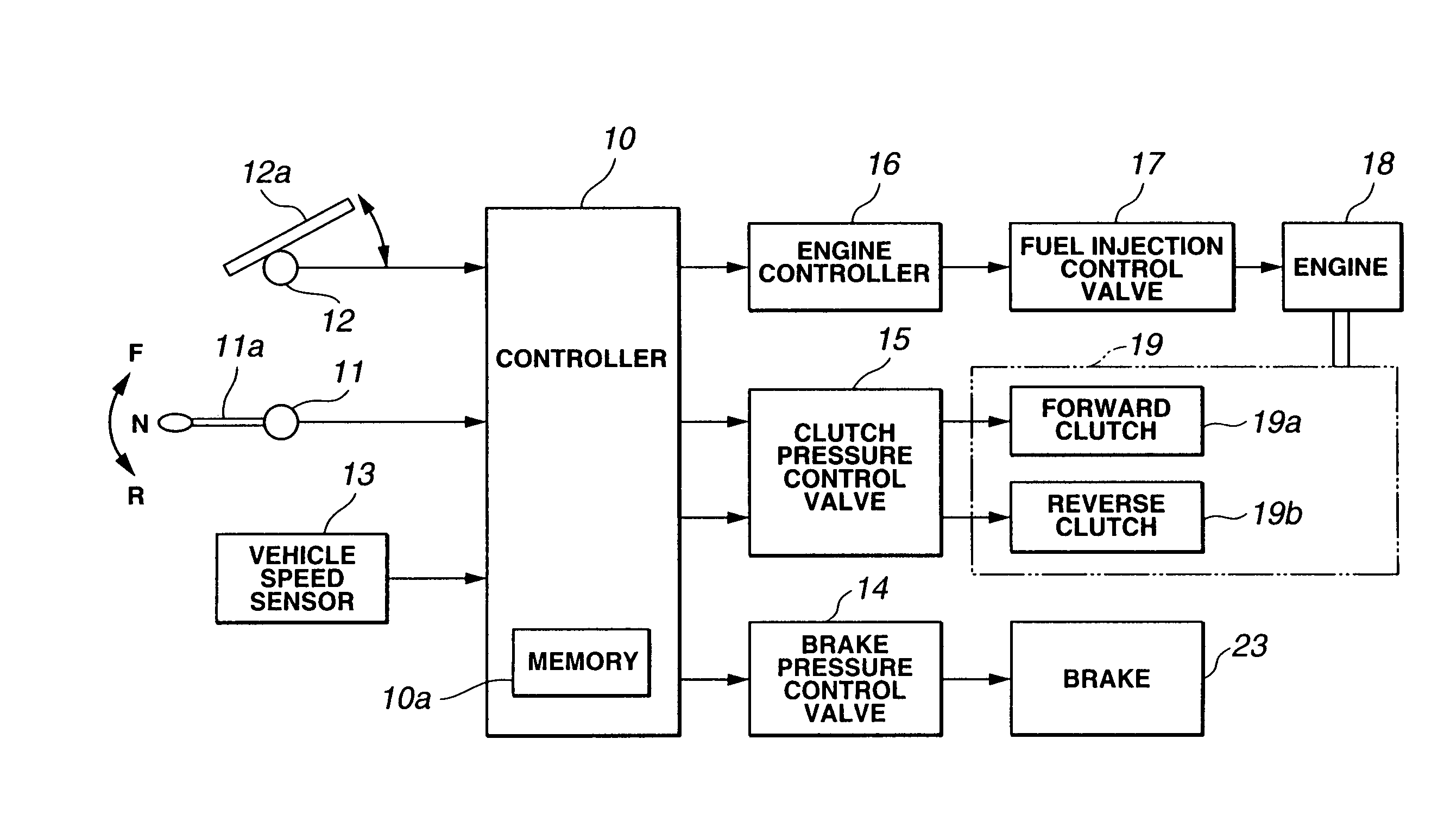

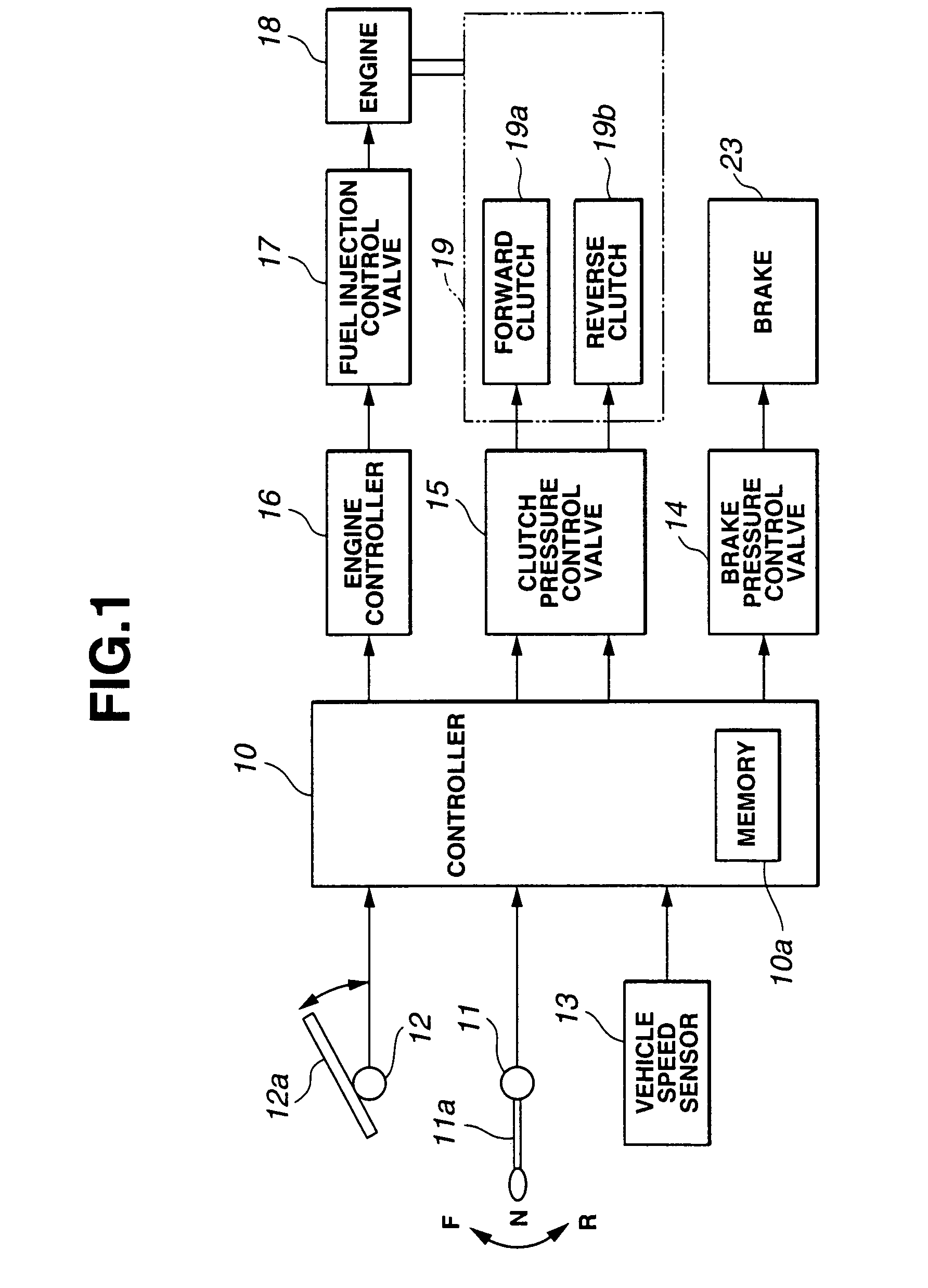

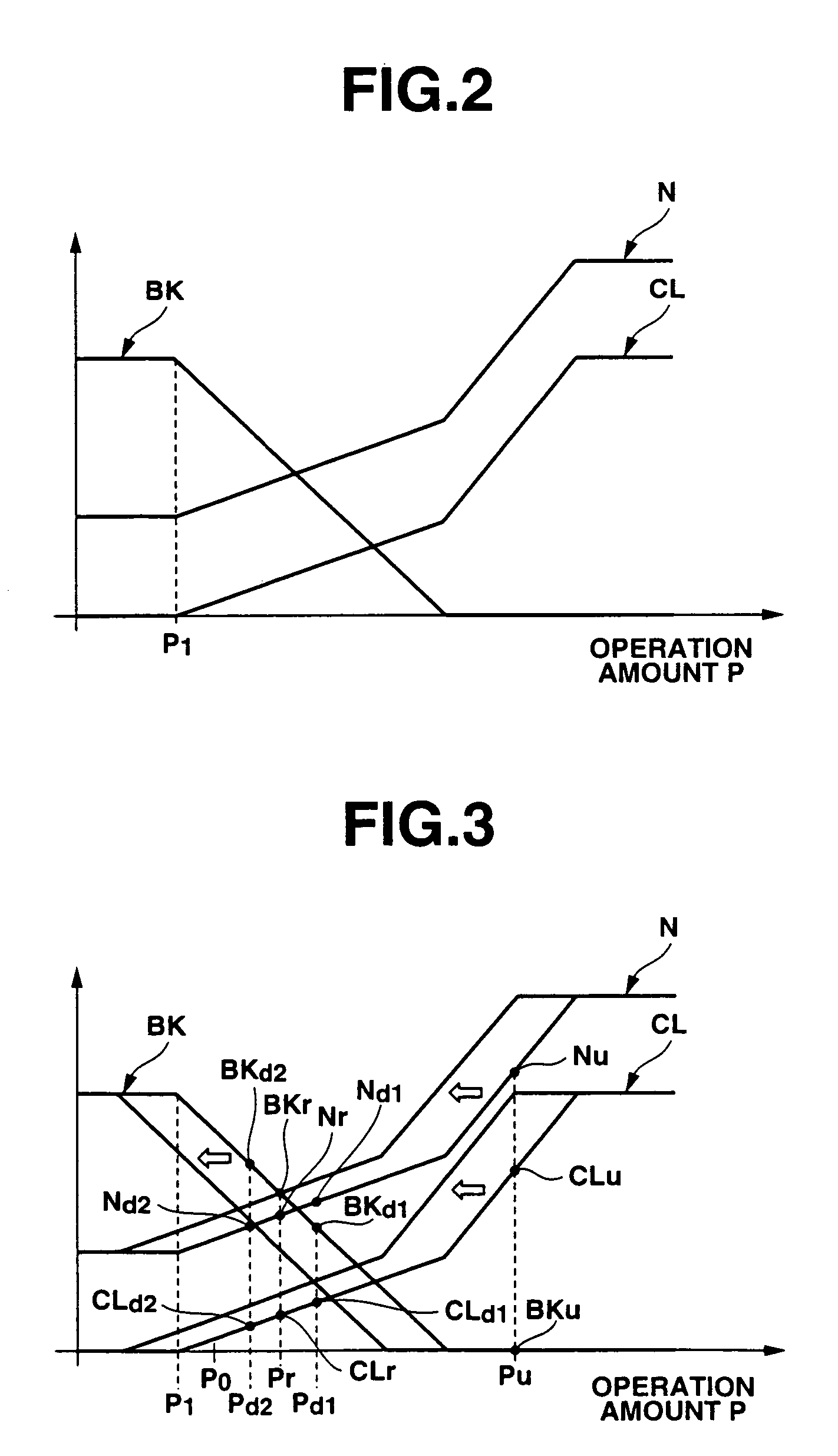

Running control device for industrial vehicle

InactiveUS7153235B2Easy to operateGood driving maneuverabilityClutchesSoil-shifting machines/dredgersRoad surfaceOperability

The present invention provides a running control device for an industrial vehicle that has superior driving operability and that allows easy starting and stopping on road surfaces that have sloped or stepped surface. The running control device for an industrial vehicle includes an engine, a sensor that detects an operation amount of an accelerator member, a transmission that has a forward clutch and reverse clutch, a brake that applies braking to the vehicle, and a controller. The controller simultaneously controls the engine revolutions, the engaging force of the forward clutch and reverse clutch and the braking force of the brake in accordance with the operation amount.

Owner:KOMATSU UTILITY +1

Material handling lift vehicle and suspension system for use therewith

Owner:BEECH ENG & MFG

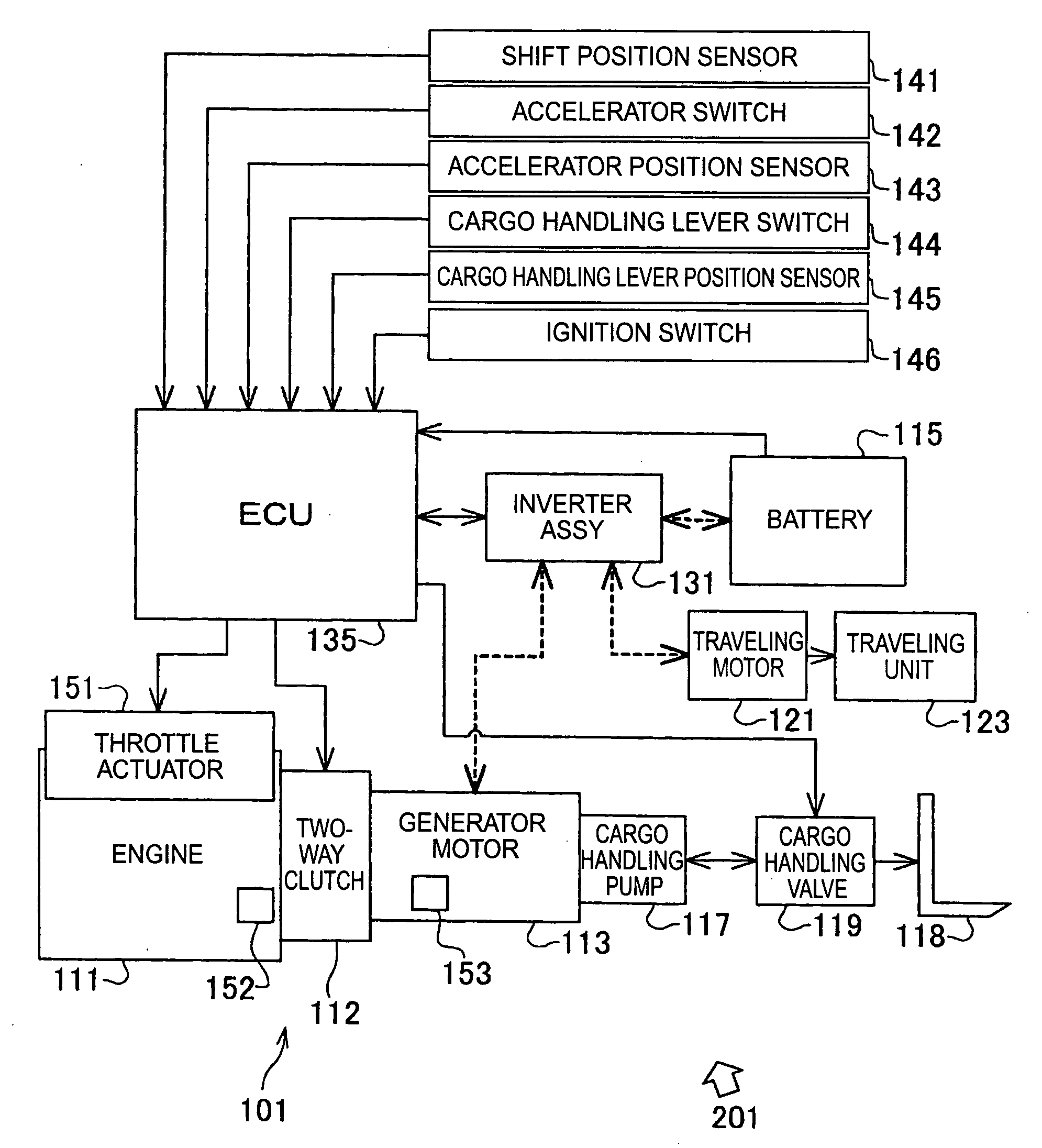

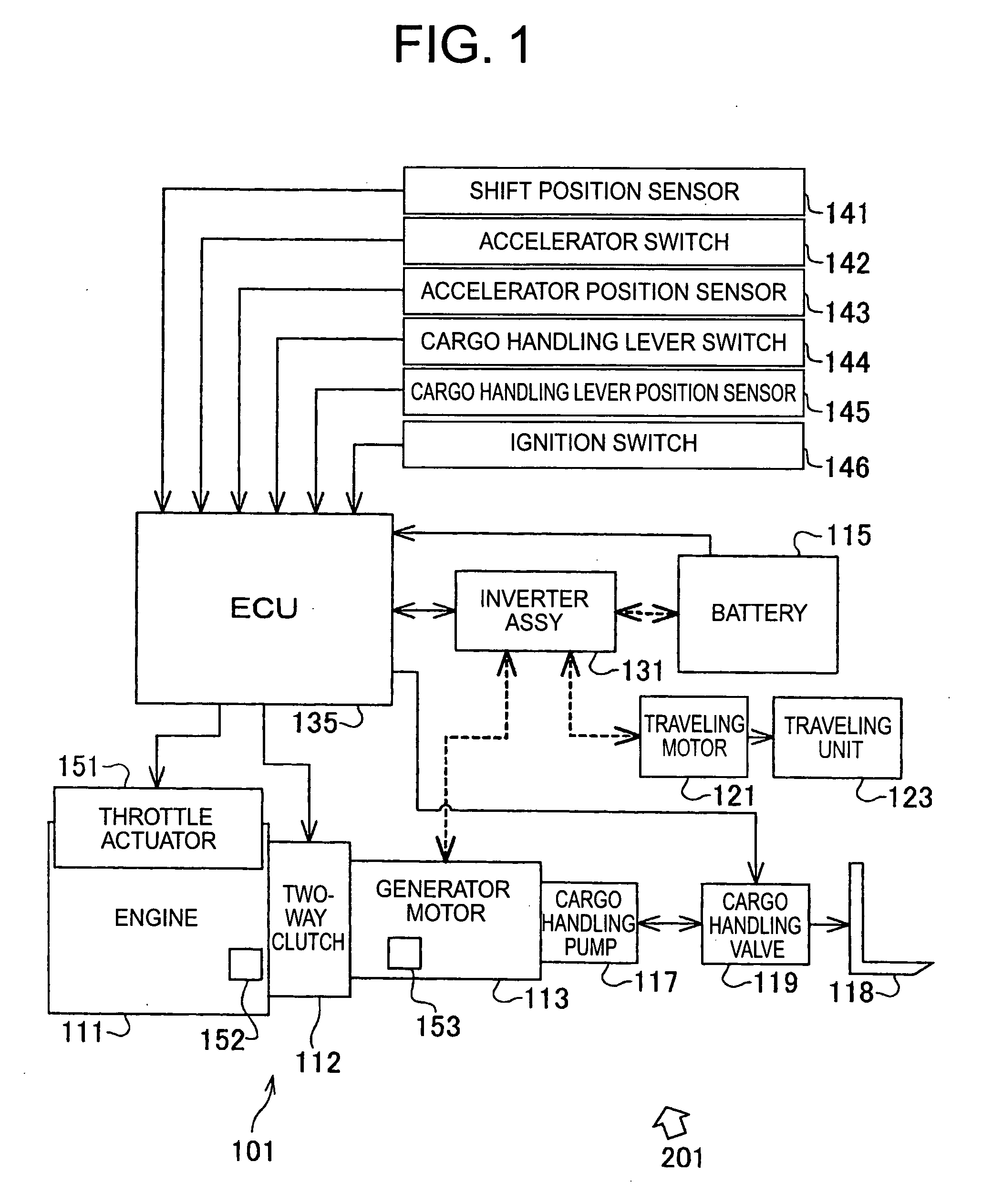

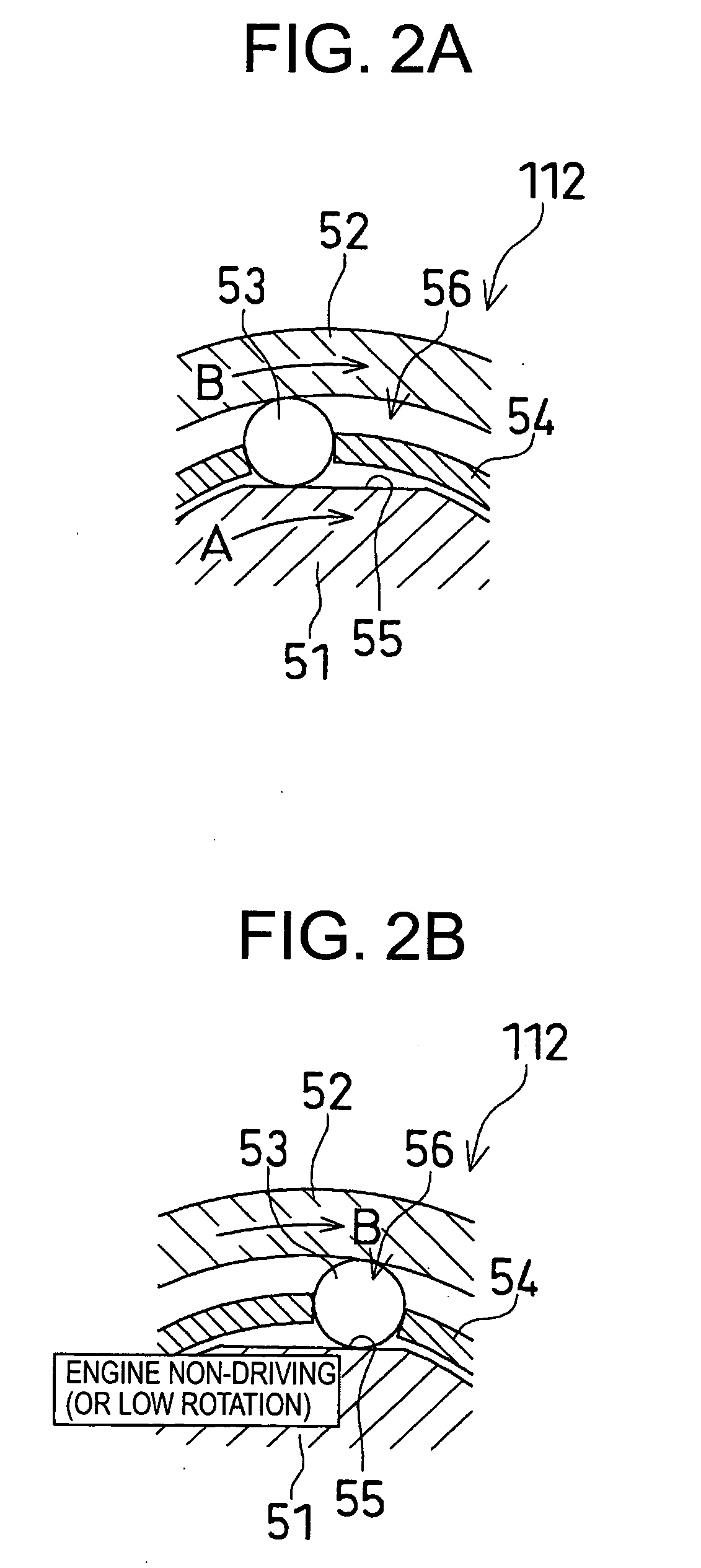

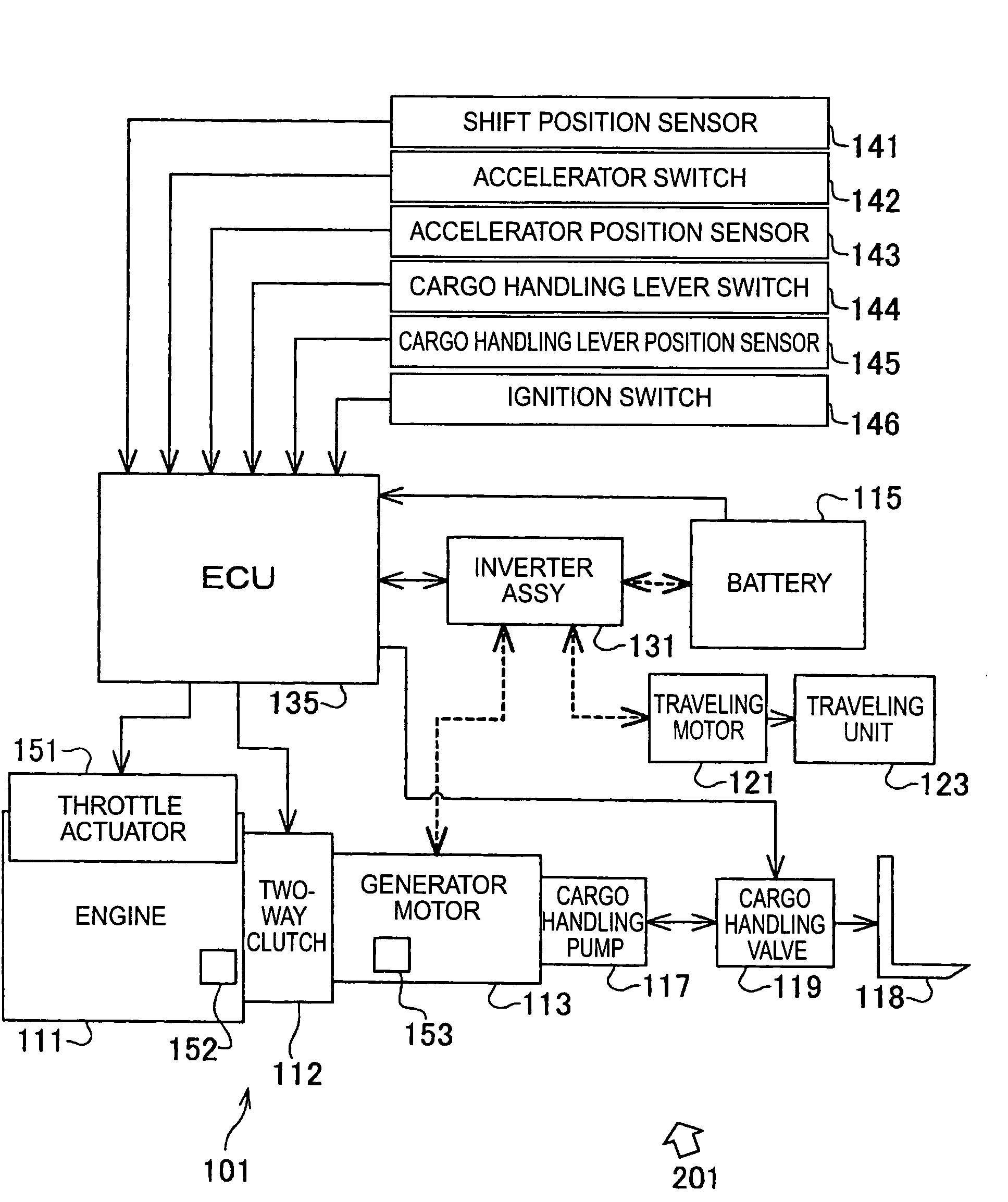

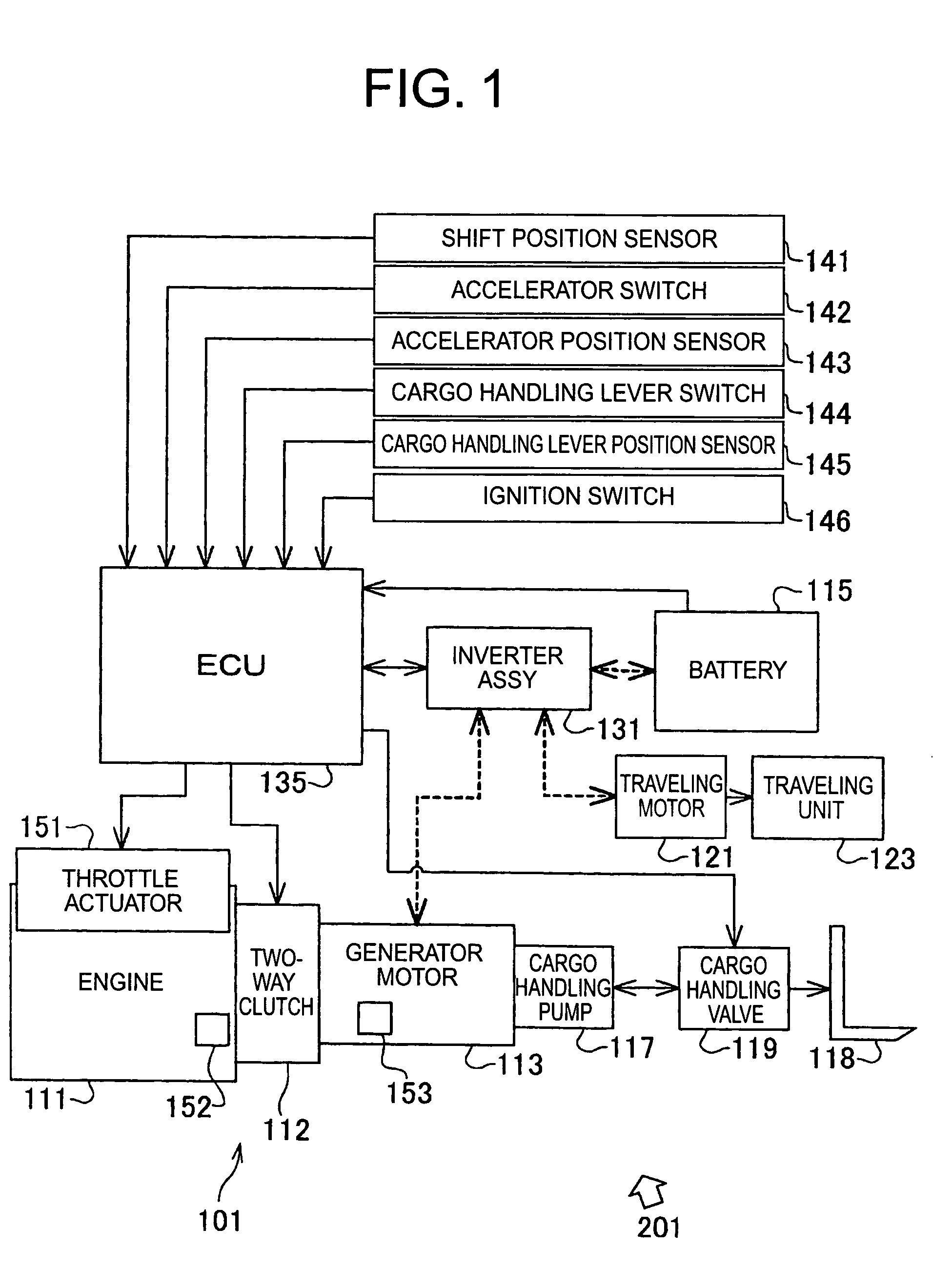

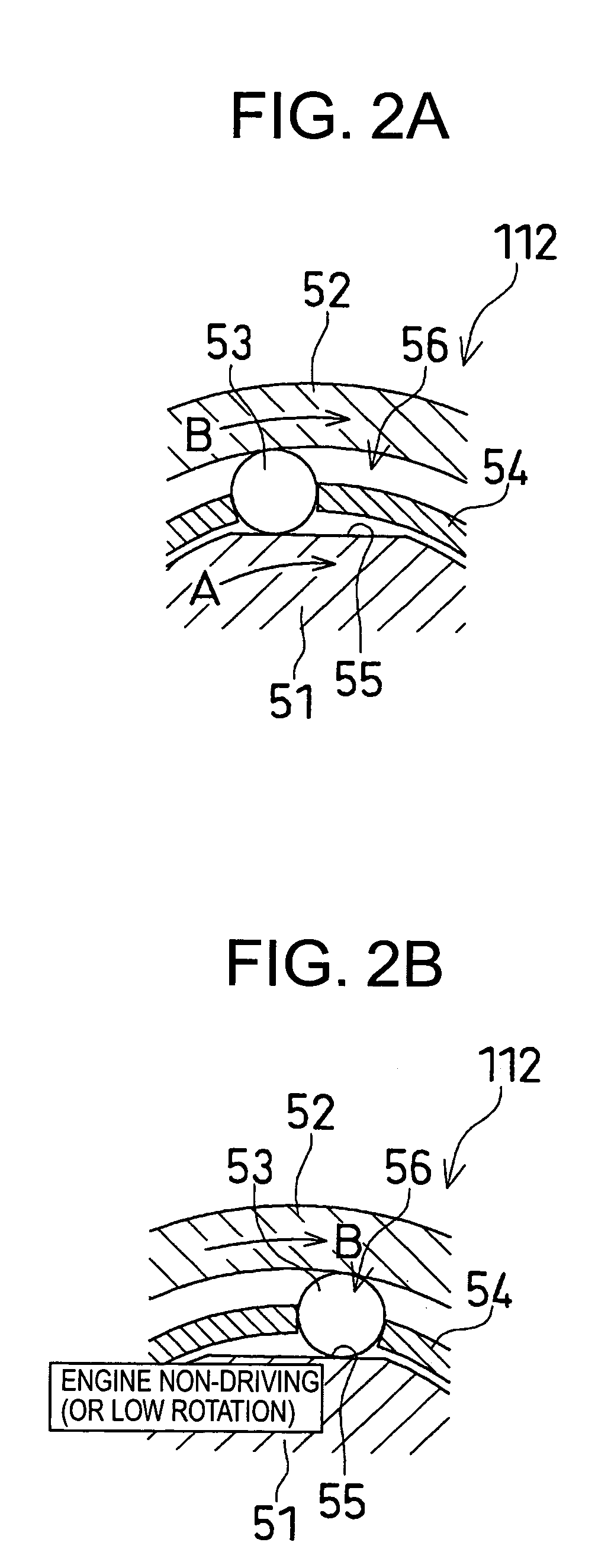

Operating apparatus for a working industrial vehicle

A two-way clutch is provided between an engine and a generator motor. Further, a battery and a cargo handling pump are provided. The generator motor is set to either a generator mode or an electric motor mode. When a cargo handling load (detected by a sensor) is small, the two-way clutch is set to a first state in which transmission of driving force from the engine to the generator motor is allowed and in which transmission of driving force in reverse is prevented. Further, when the engine is stopped or idled, the cargo handling pump is driven by the generator motor in the electric motor mode. When, during the above operation, the load increases to a level above a predetermined value, an increase in output of the generator motor and an increase in engine RPM are started, and when the engine RPM becomes equal to the RPM of the generator motor, which previously increased, the two-way clutch in the first state is connected, and the cargo handling pump is driven by the engine.

Owner:TOYOTA IND CORP

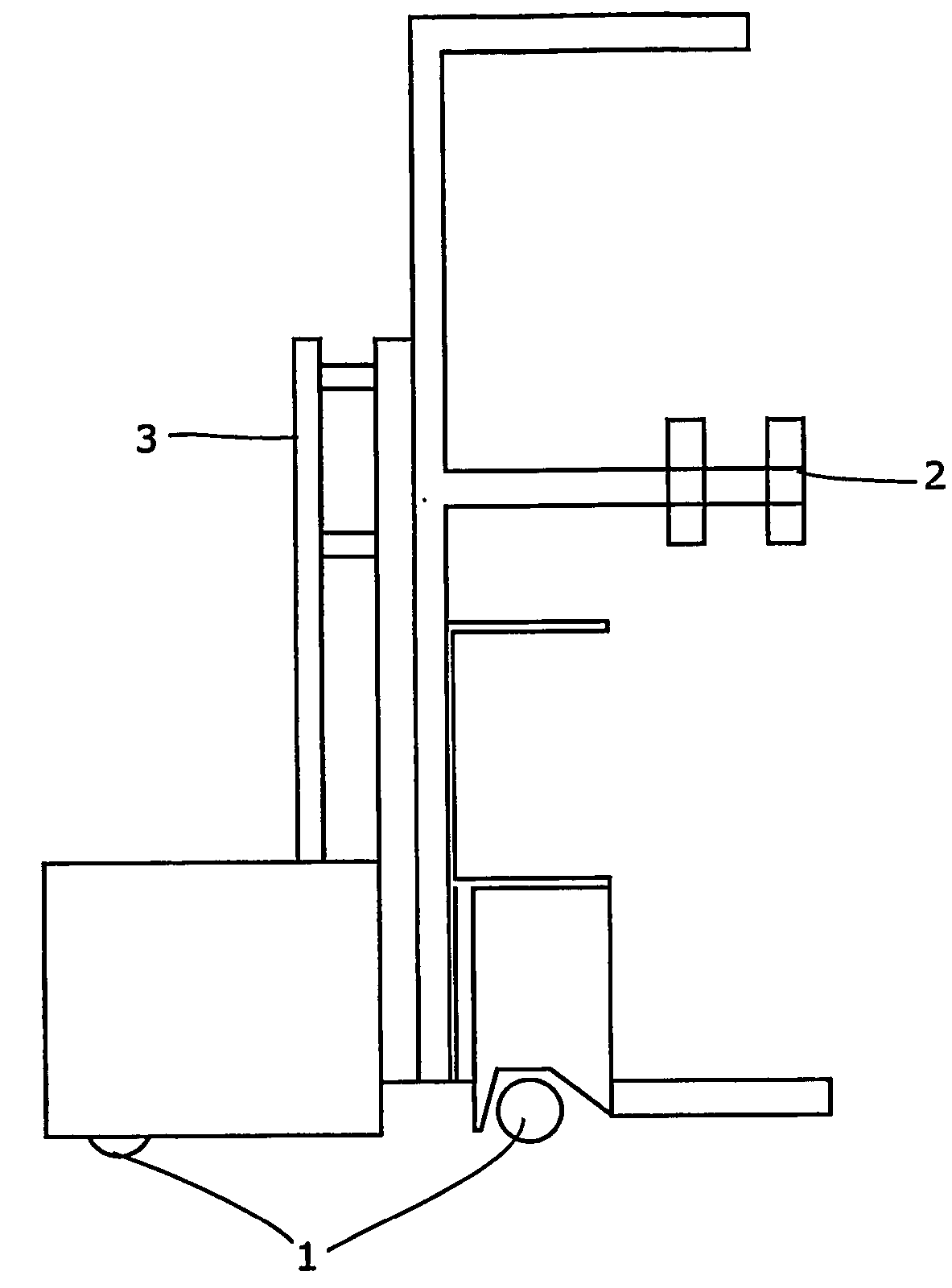

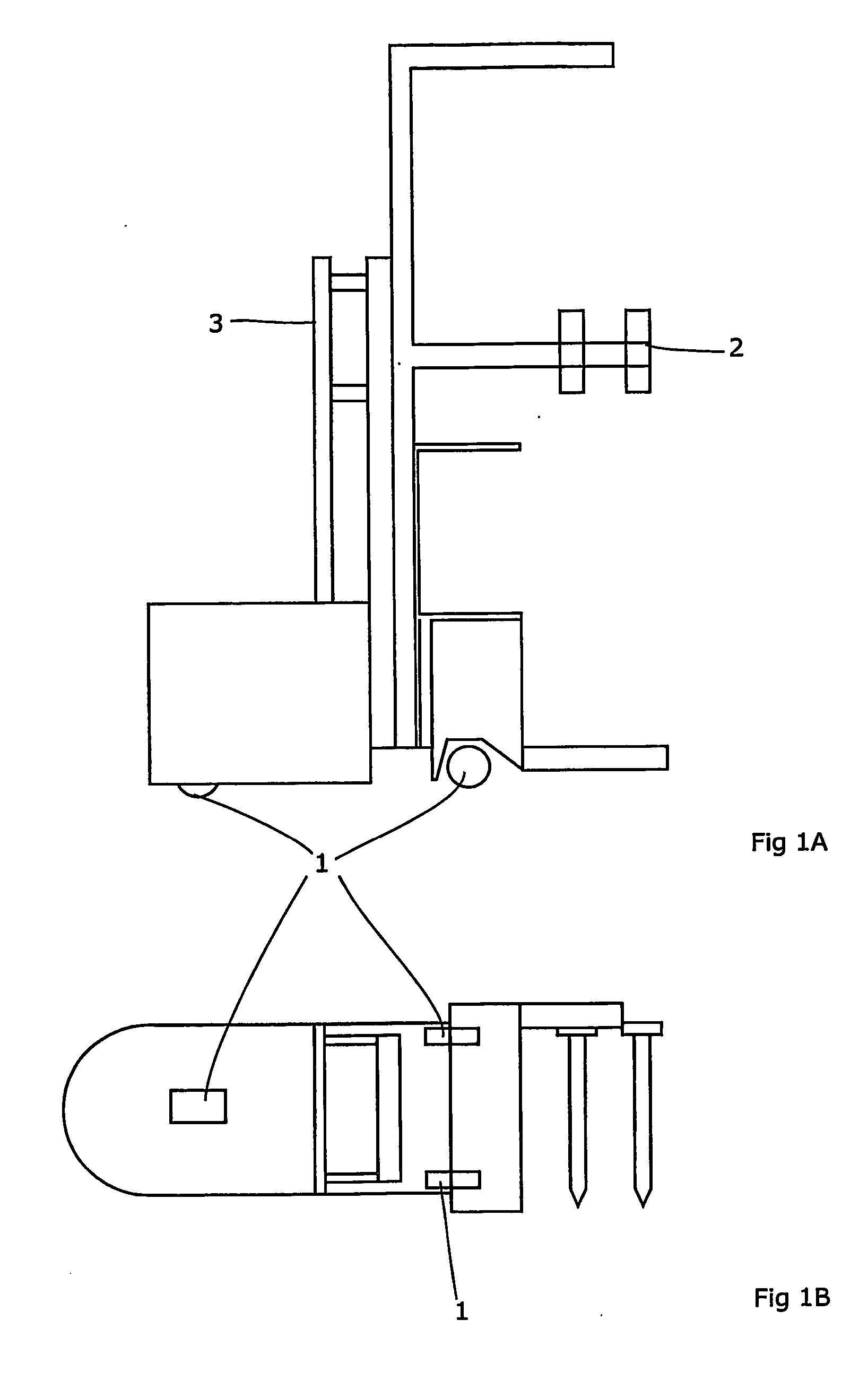

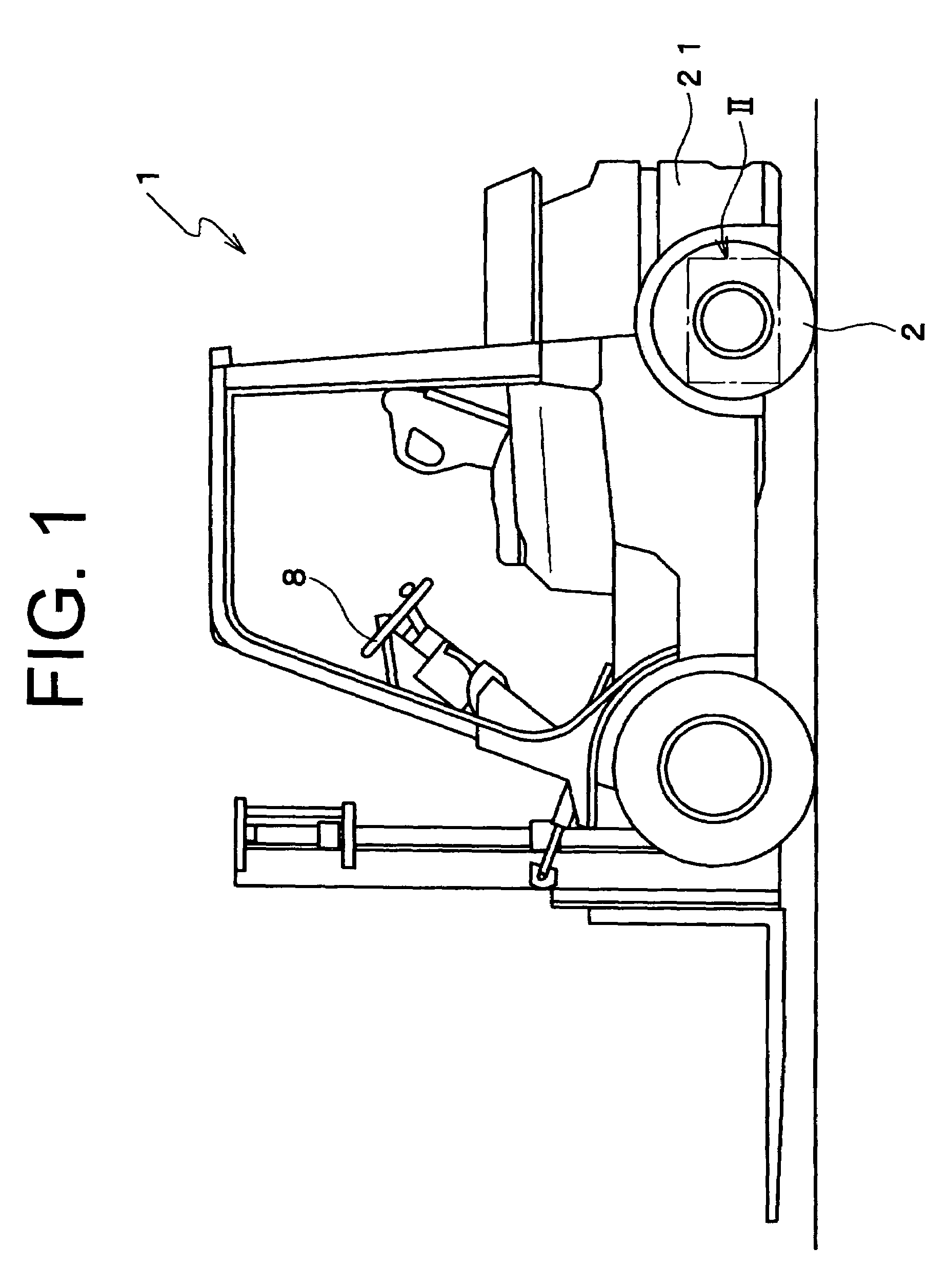

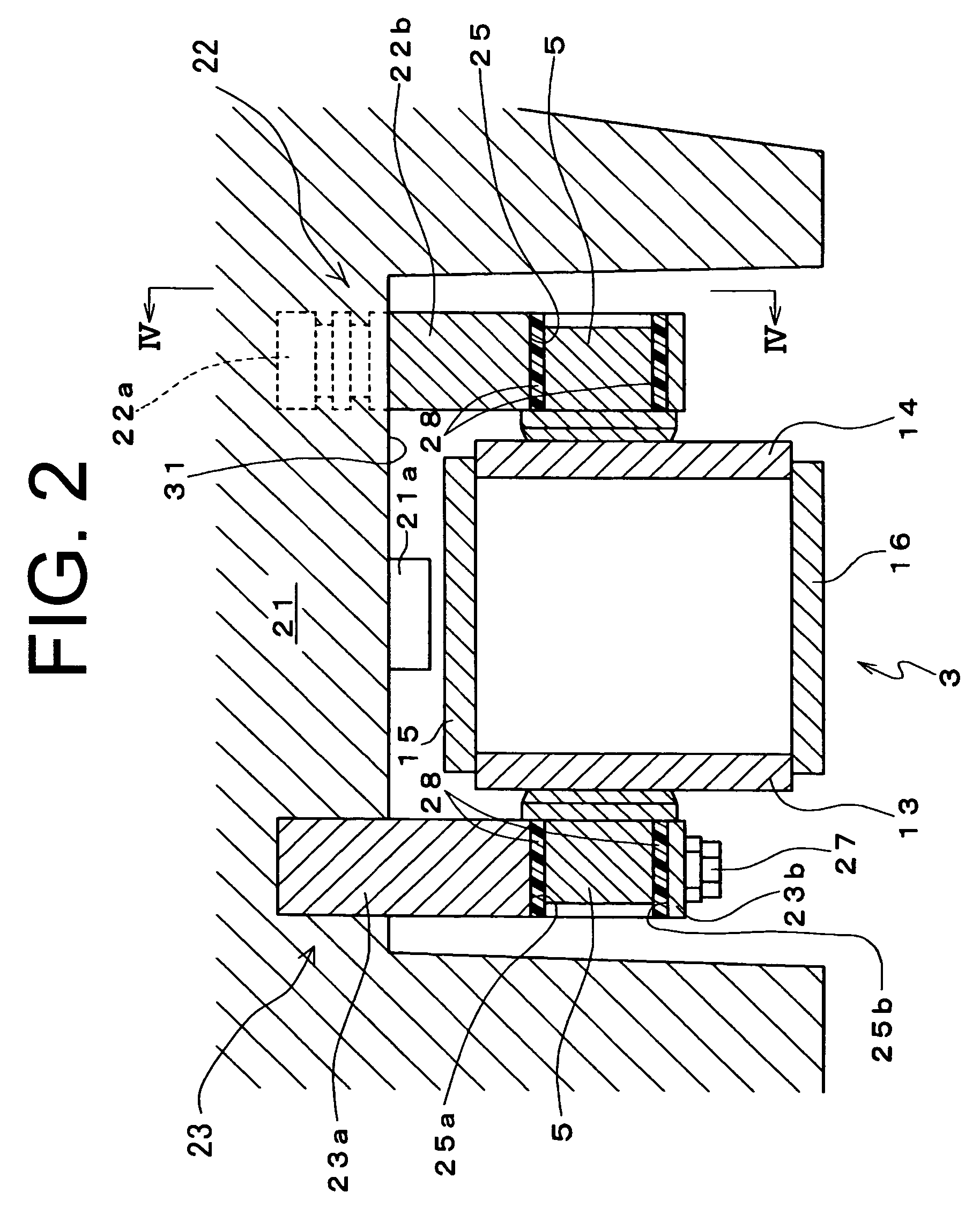

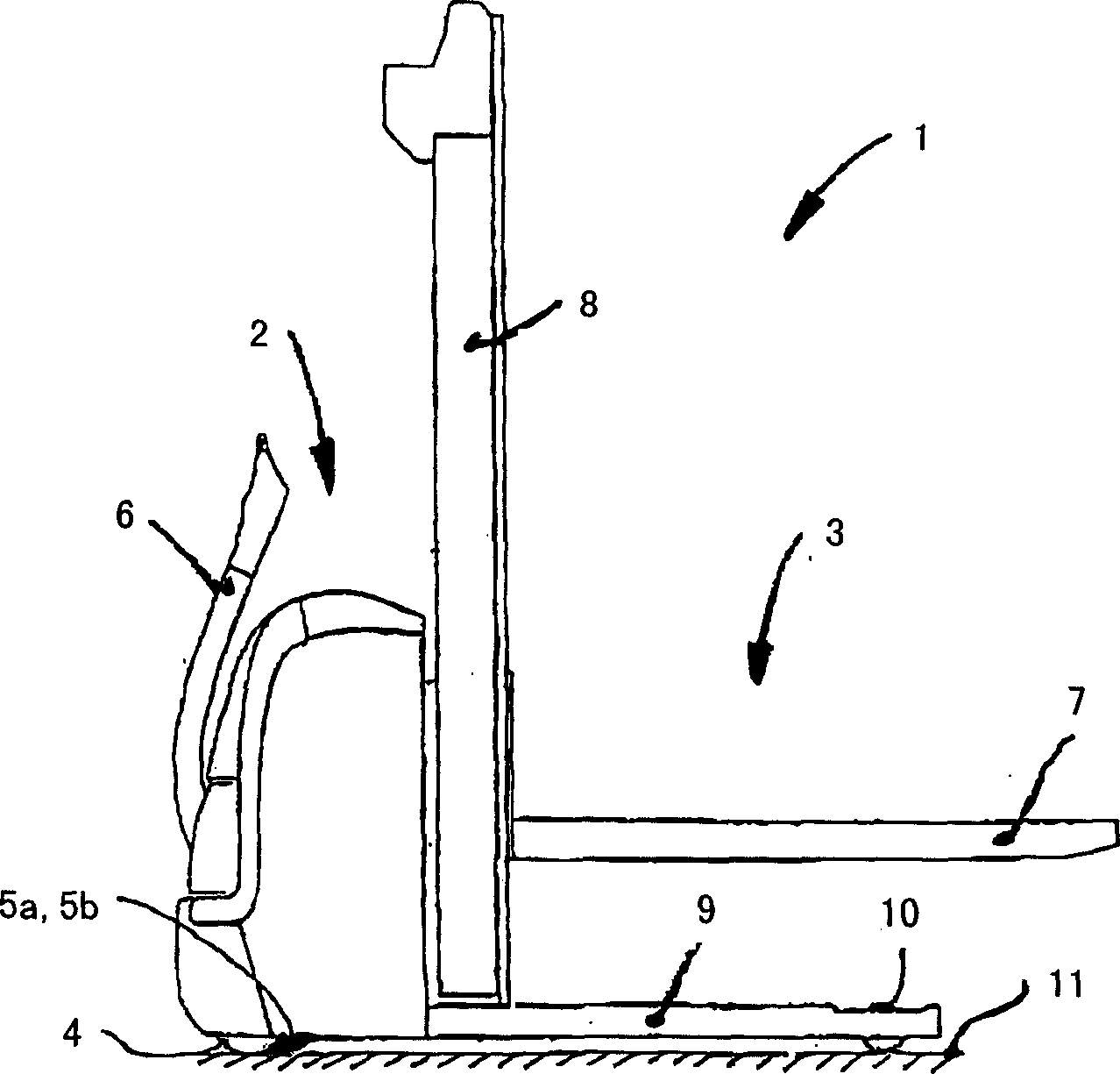

Fork lift trucks

InactiveUS20060182588A1Simple and inexpensiveMaintain standardSuspensionsSafety devices for lifting equipmentsEngineeringMechanical engineering

A fork lift truck for moving a load, comprising a load bearing member (3) for carrying the load, wherein the truck comprises means (4, 5, 15, 19) for adjusting the vertical axis of the load bearing member to maintain it substantially parallel to the axis of gravitational pull on the load, when the truck travels along a surface having varying degrees of flatness or deviance from horizontal.

Owner:BECKETT JAMES LEONARD

Suspension system

InactiveUS7726665B2Improve securityProcess stabilityPedestrian/occupant safety arrangementVehicle fittings for liftingHydraulic cylinderLine tubing

A suspension system for an agricultural or construction industry vehicle is described. The suspension system comprises two hydraulic cylinders, which support a frame in relation to an axle of the vehicle, the hydraulic cylinders each having a piston-side chamber and a piston rod-side chamber and each of the chambers of the hydraulic cylinders being connectable to one another via connecting lines provided with a switch valve, a first supply line, which can be connected via a switch valve to the piston-side connecting line of the first hydraulic cylinder, a second supply line, which can be connected via a switch valve to the piston-side connecting line of the second hydraulic cylinder, a hydraulic accumulator, in each case connectable to the supply lines via proportionally adjustable orifices, a hydraulic source, a hydraulic tank, a control valve device, and an electronic control unit. In order to prevent the activation of a suspension state in critical vehicle states, means for the detection and compensation of load states of the vehicle are provided in the suspension system.

Owner:DEERE & CO

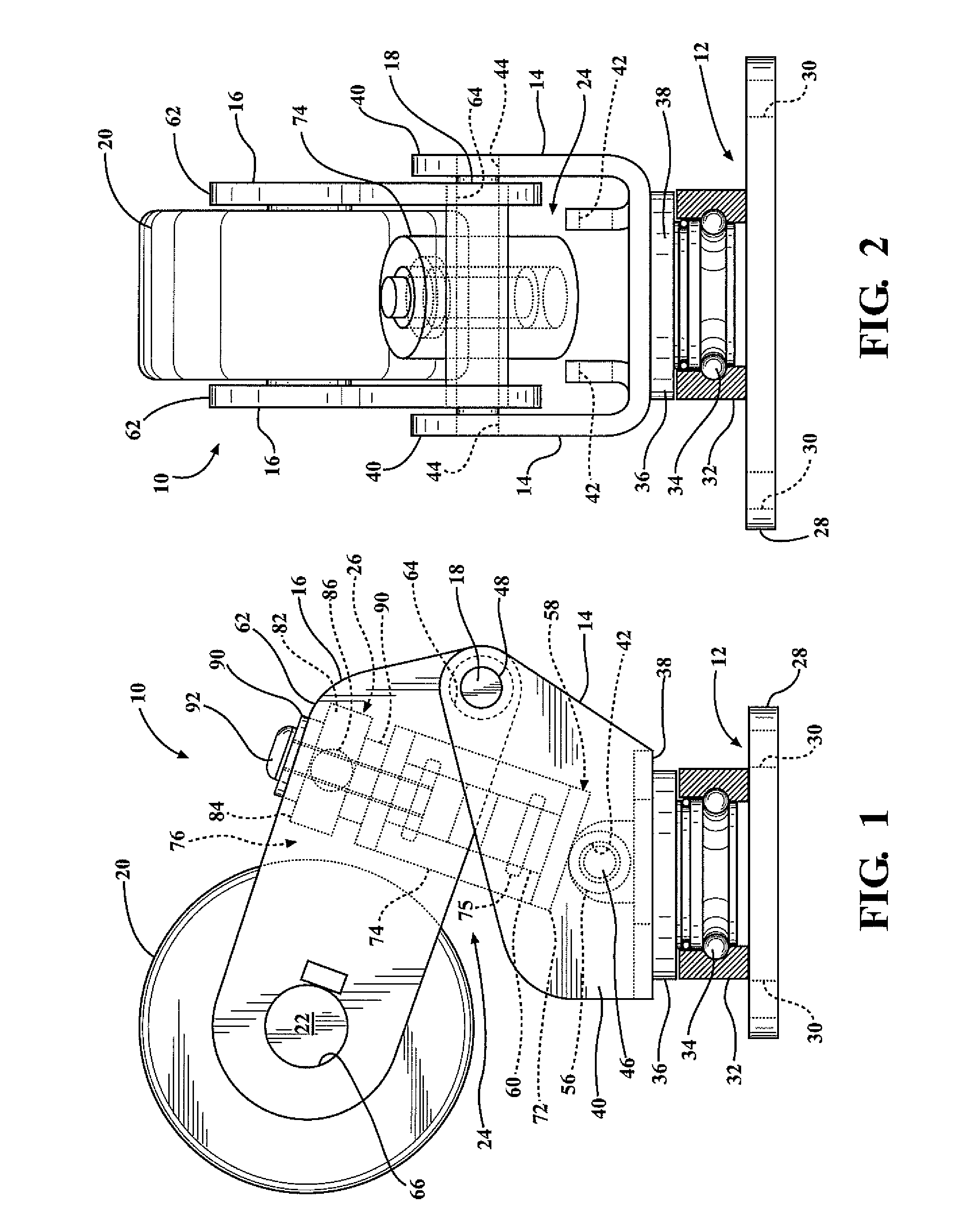

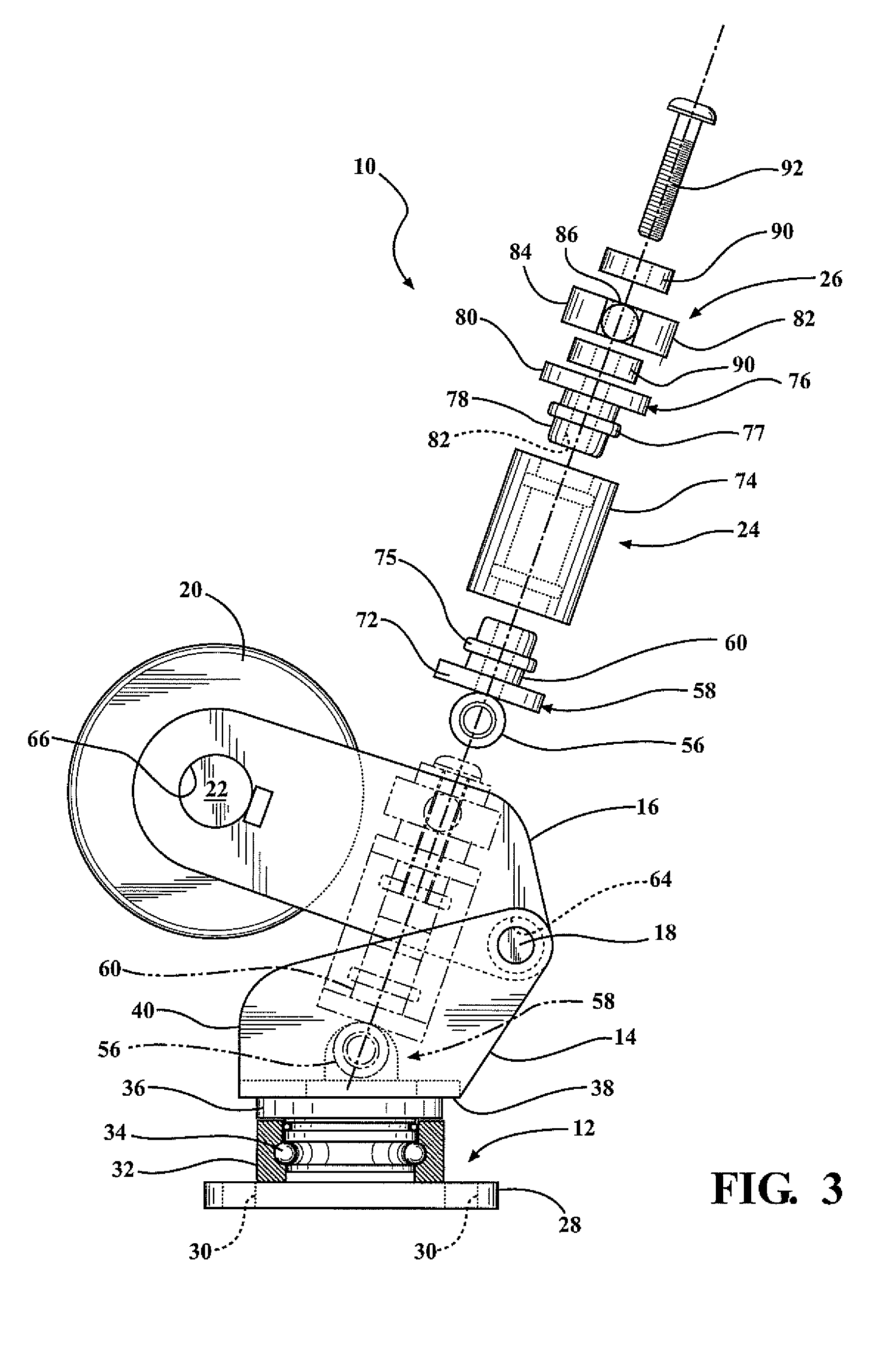

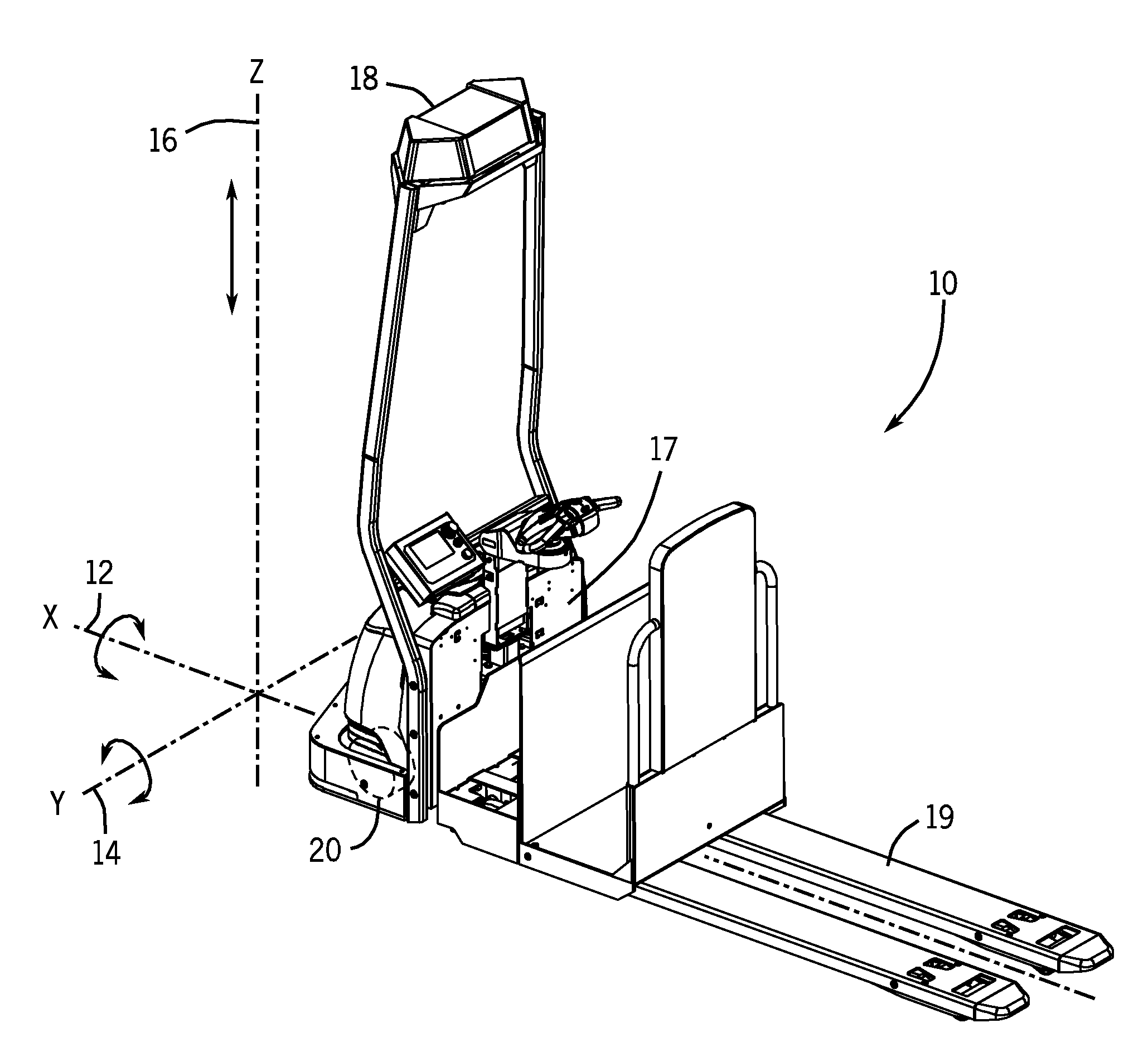

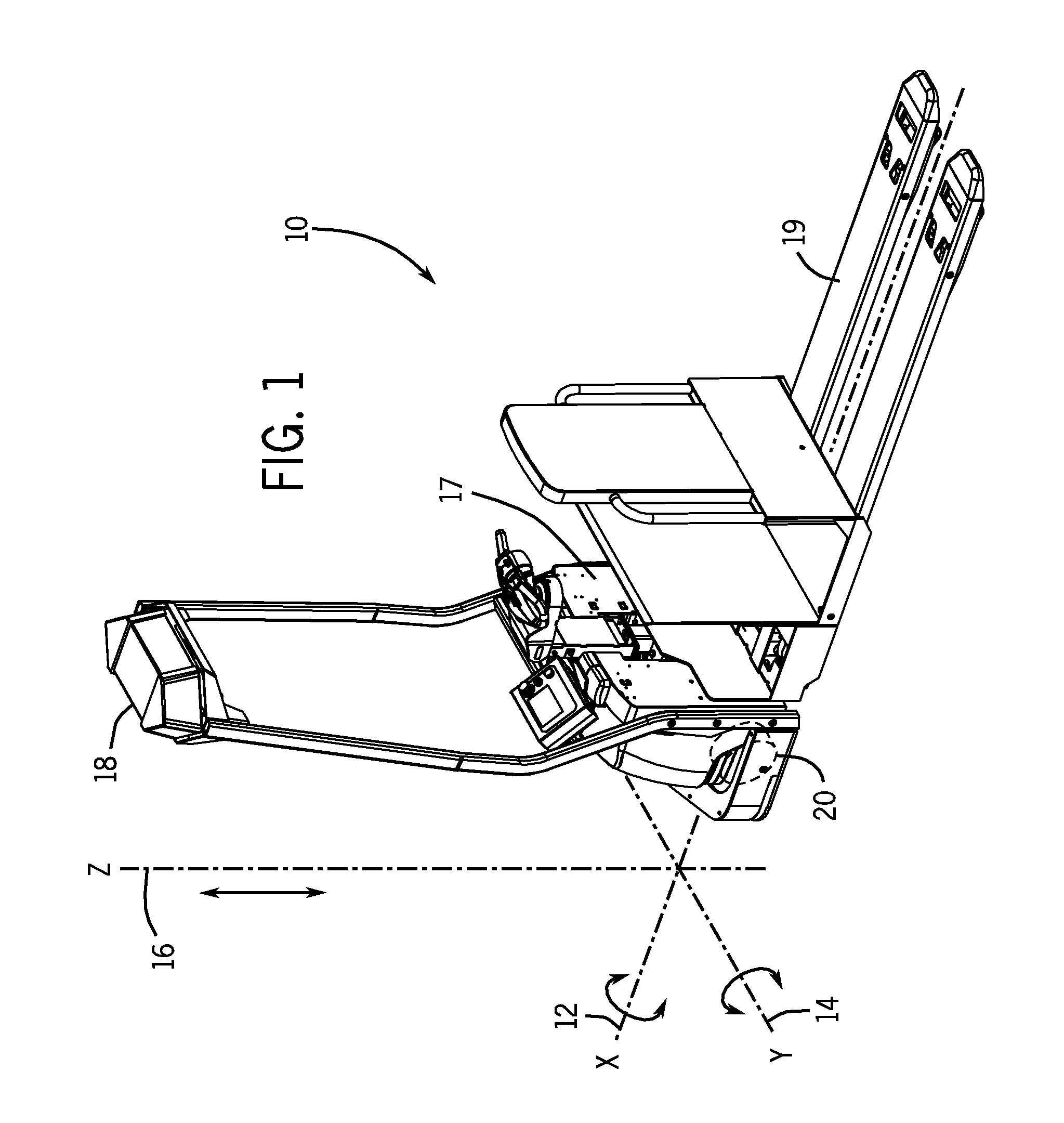

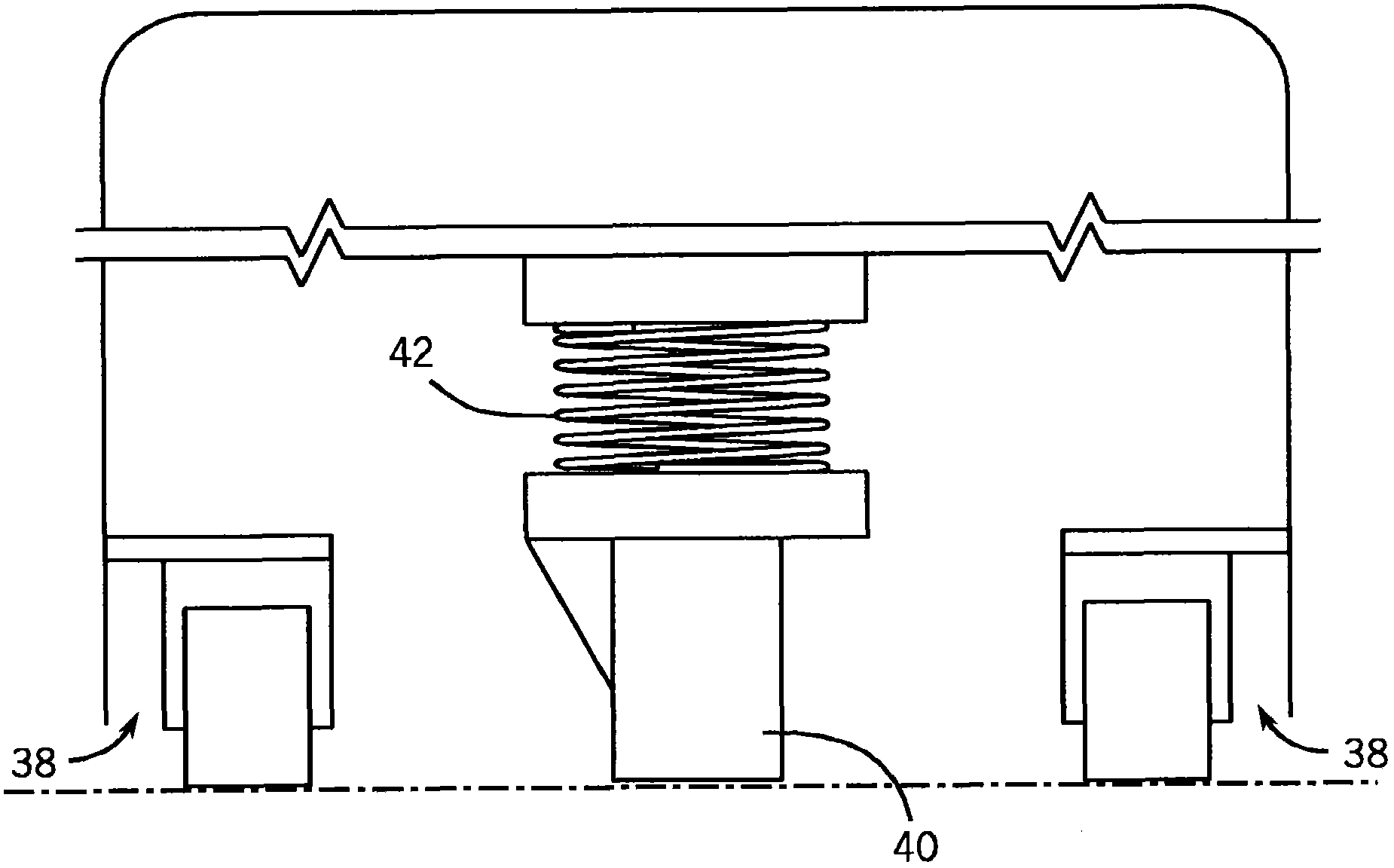

Dynamic vibration control systems and methods for industrial lift trucks

ActiveUS9403667B2Smooth motionReduce and eliminate motionSafety devices for lifting equipmentsSpringsControl systemTruck

Owner:RAYMOND LTD

Turn stability systems and methods for lift trucks

Owner:RAYMOND LTD

Improvements in or relating to fork lift trucks

InactiveCN1771187ASafety devices for lifting equipmentsResilient suspensionsControl theoryMechanical engineering

A fork lift truck for moving a load, comprising a load bearing member ( 3 ) for carrying the load, wherein the truck comprises means ( 4, 5, 15, 19 ) for adjusting the vertical axis of the load bearing member to maintain it substantially parallel to the axis of gravitational pull on the load, when the truck travels along a surface having varying degrees of flatness or deviance from horizontal.

Owner:詹姆斯·伦纳德·贝克特

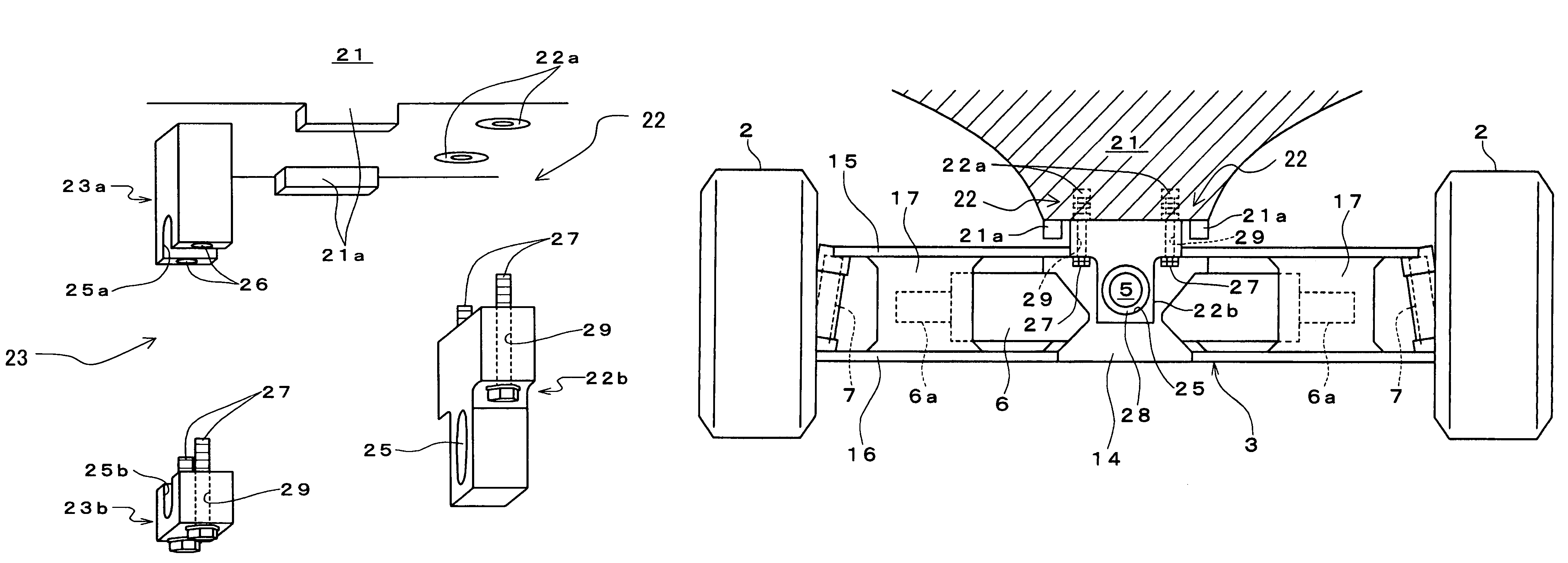

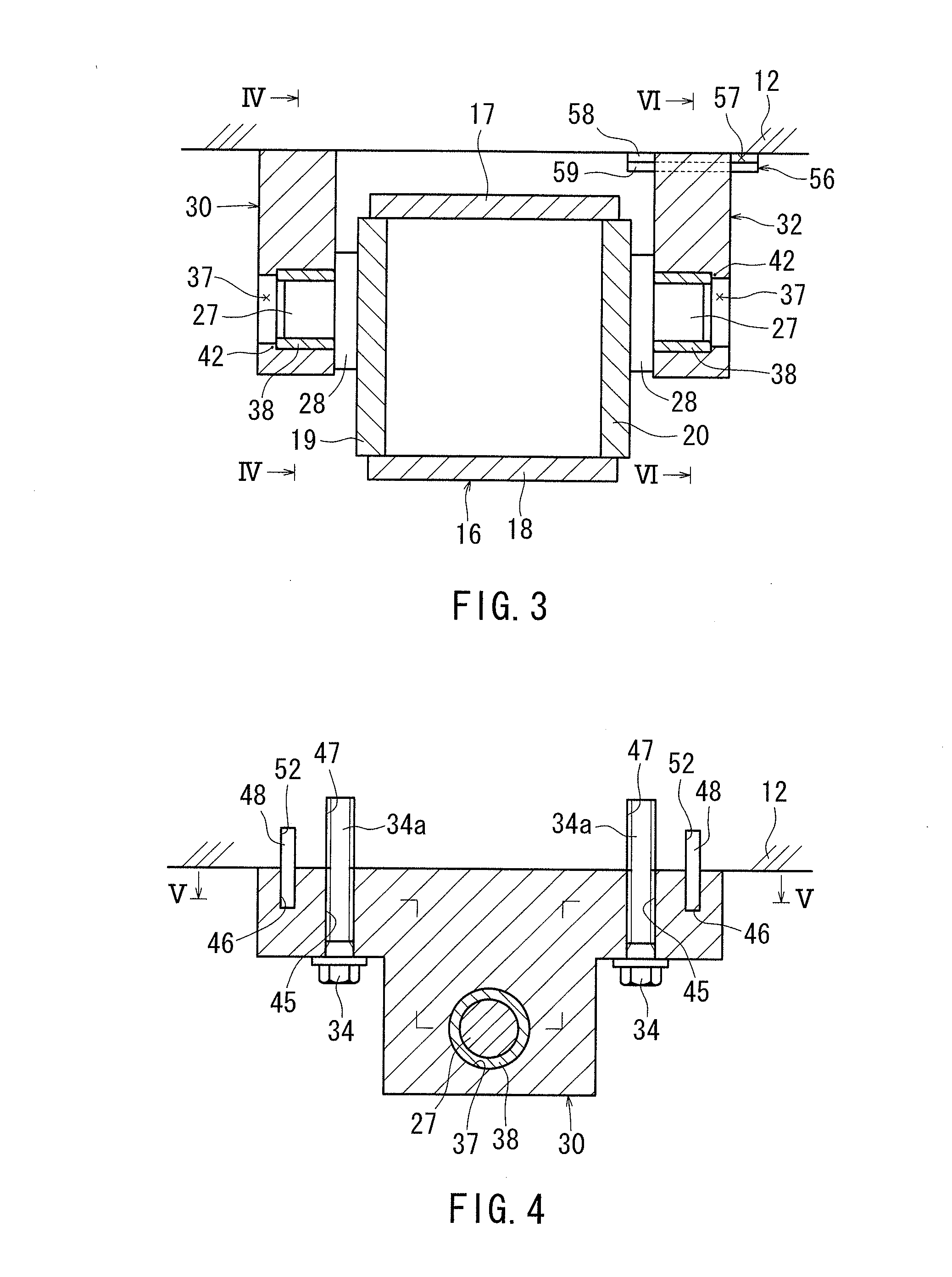

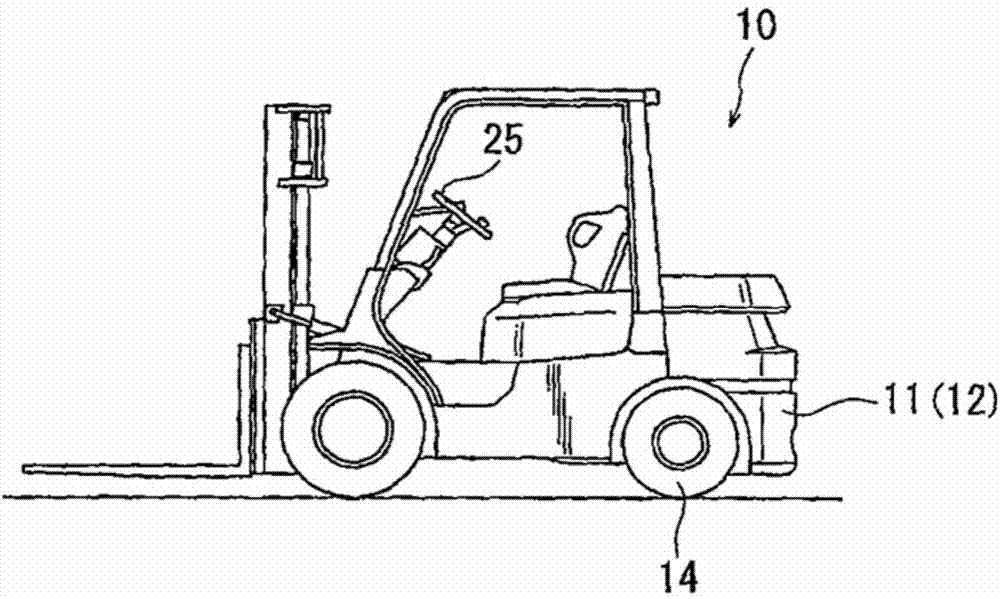

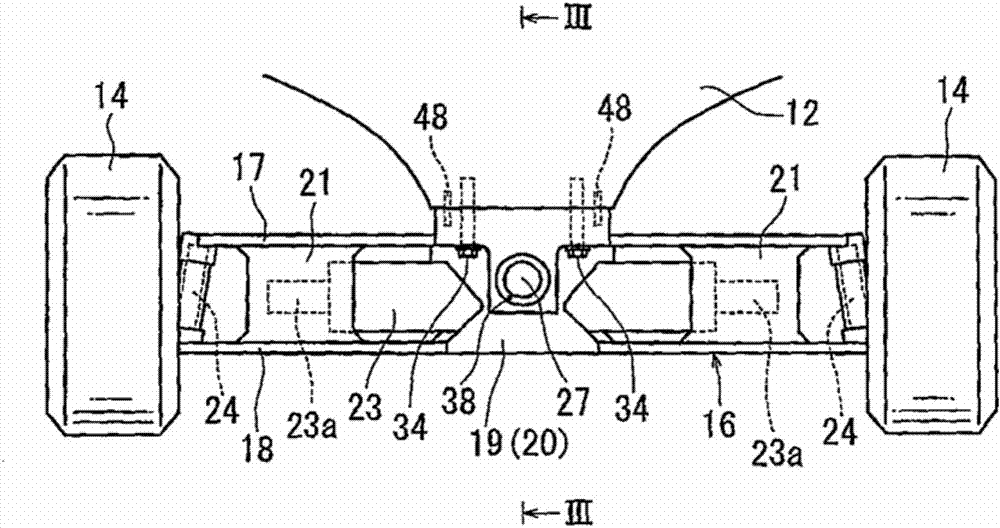

Axle supporting structure for industrial vehicle and industrial vehicle having the same

InactiveUS7204499B2High strengthLow costVehicle cleaning apparatusRigid suspensionsAutomotive engineering

An axle supporting structure for supporting an axle beam for an industrial vehicle includes a center pin, a pair of axle supporting units and a counterweight. The center pin protrudes from the axle beam. Each axle supporting unit has formed therethrough an insertion hole in which the center pin is inserted. The axle supporting unit has an upper axle supporting member and a lower axle supporting member which is detachably connected to the upper axle supporting member. The pair of axle supporting units is spaced from each other in a traveling direction of the vehicle. The center pin is rotatably supported between the pair of axle supporting units. The upper axle supporting members of the axle supporting units are cast in the counterweight.

Owner:TOYOTA IND CORP

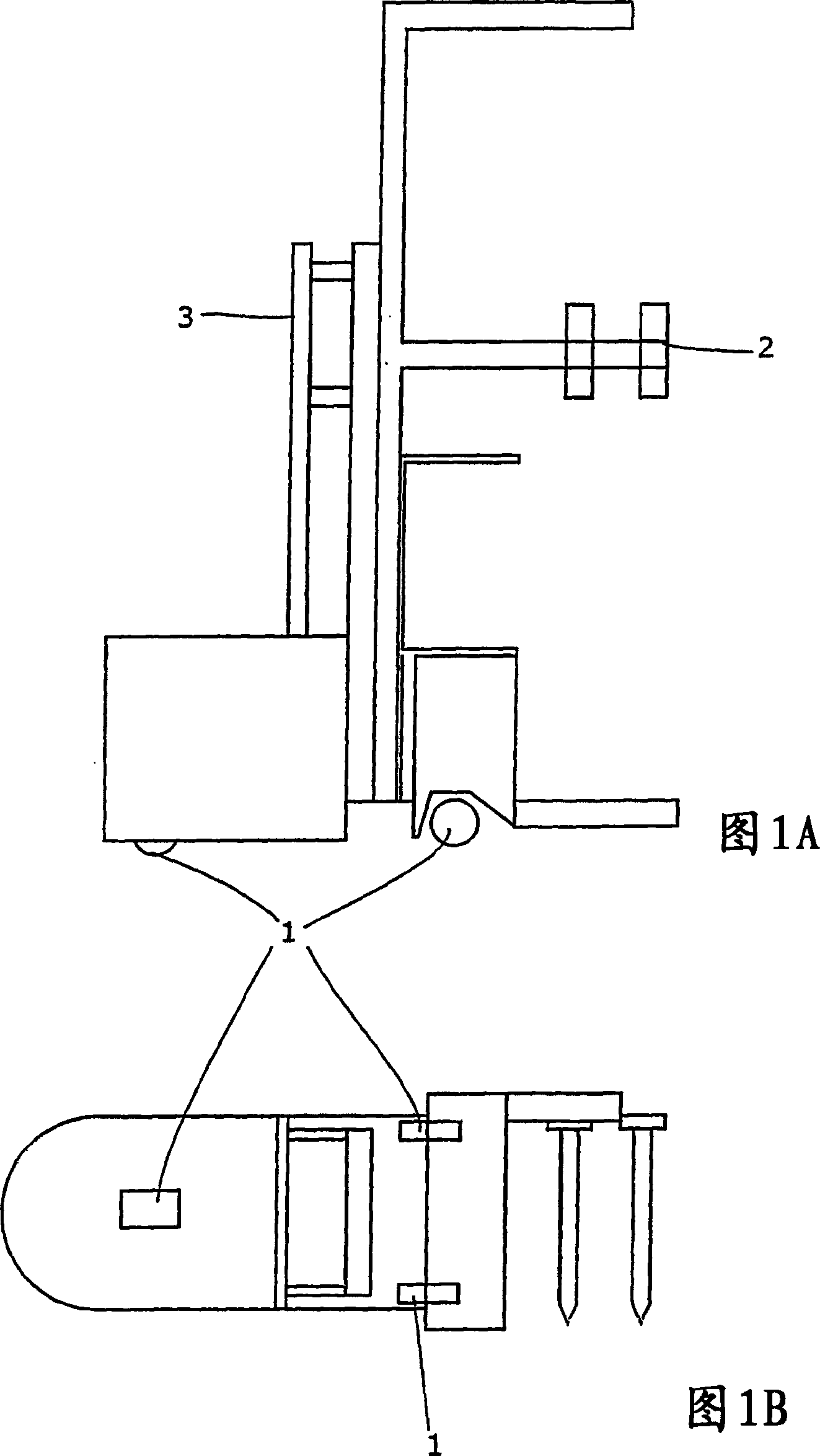

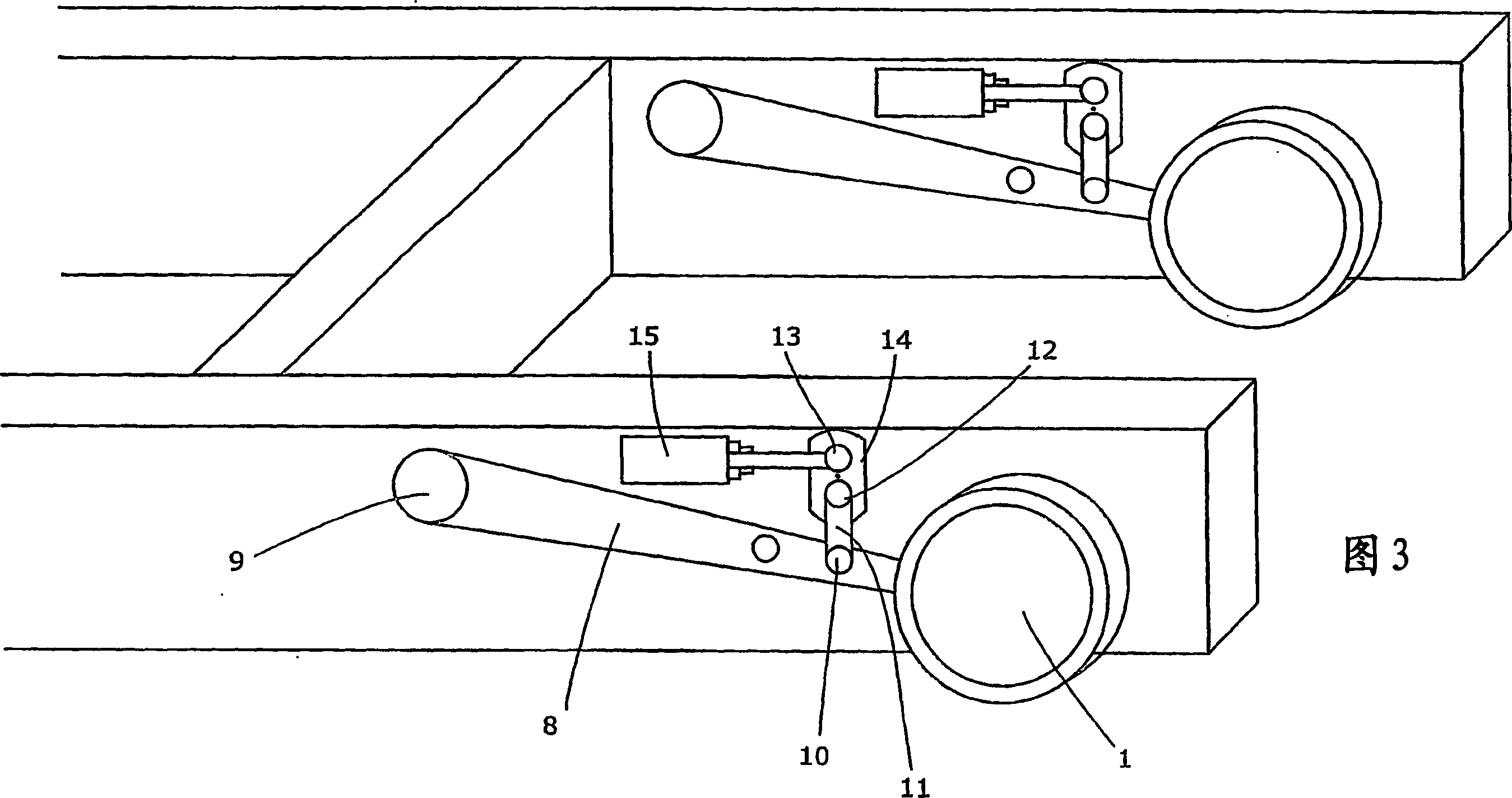

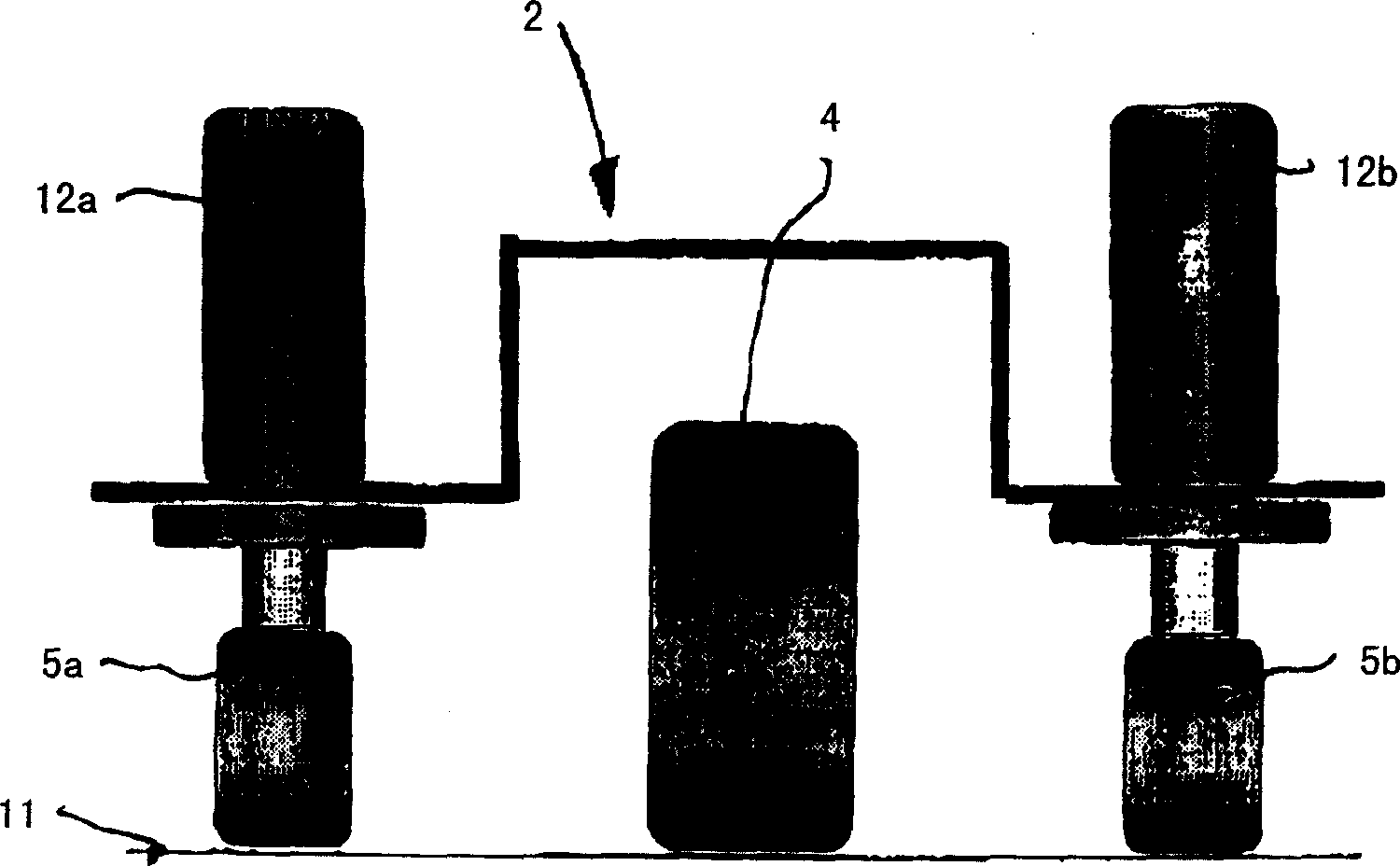

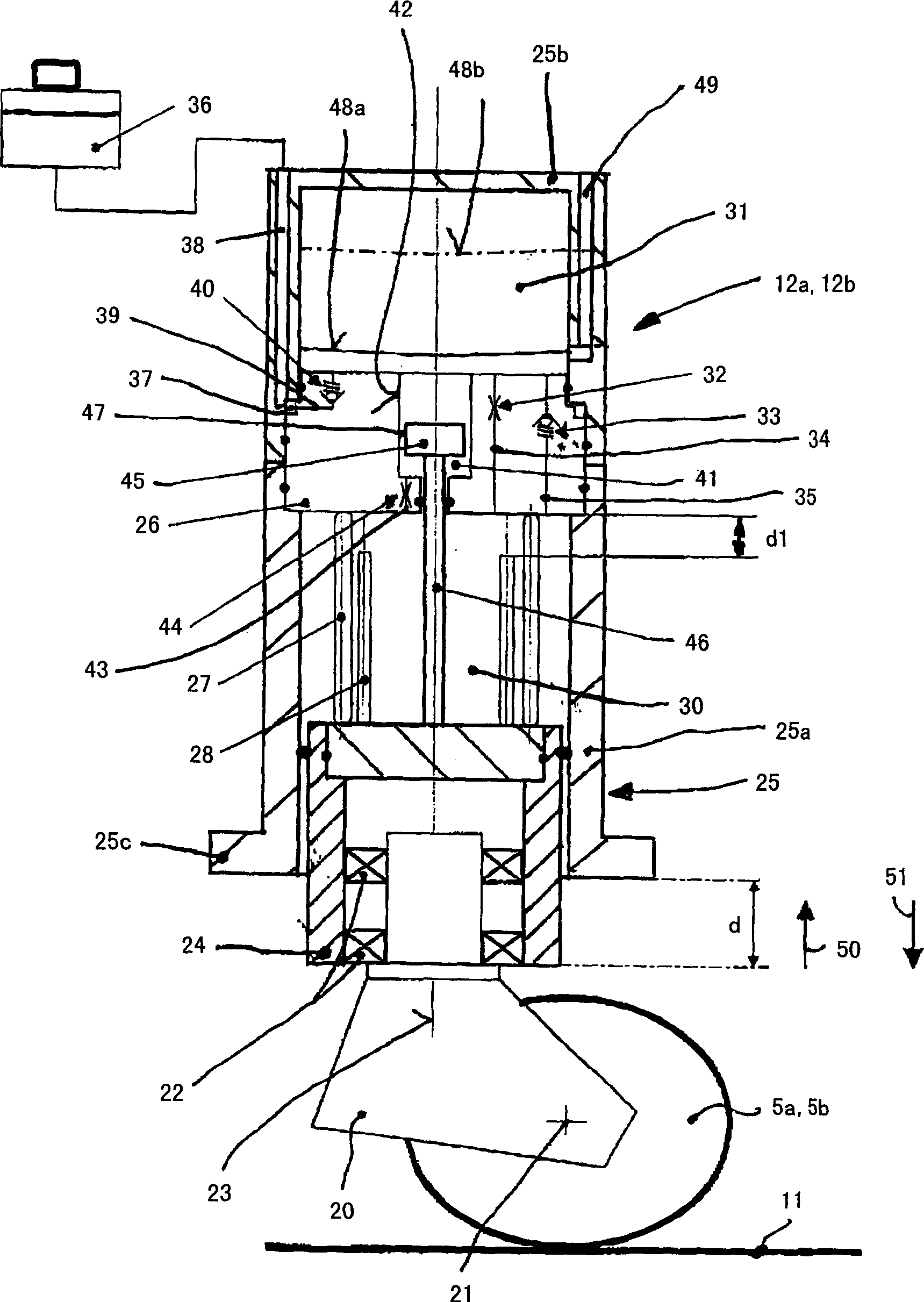

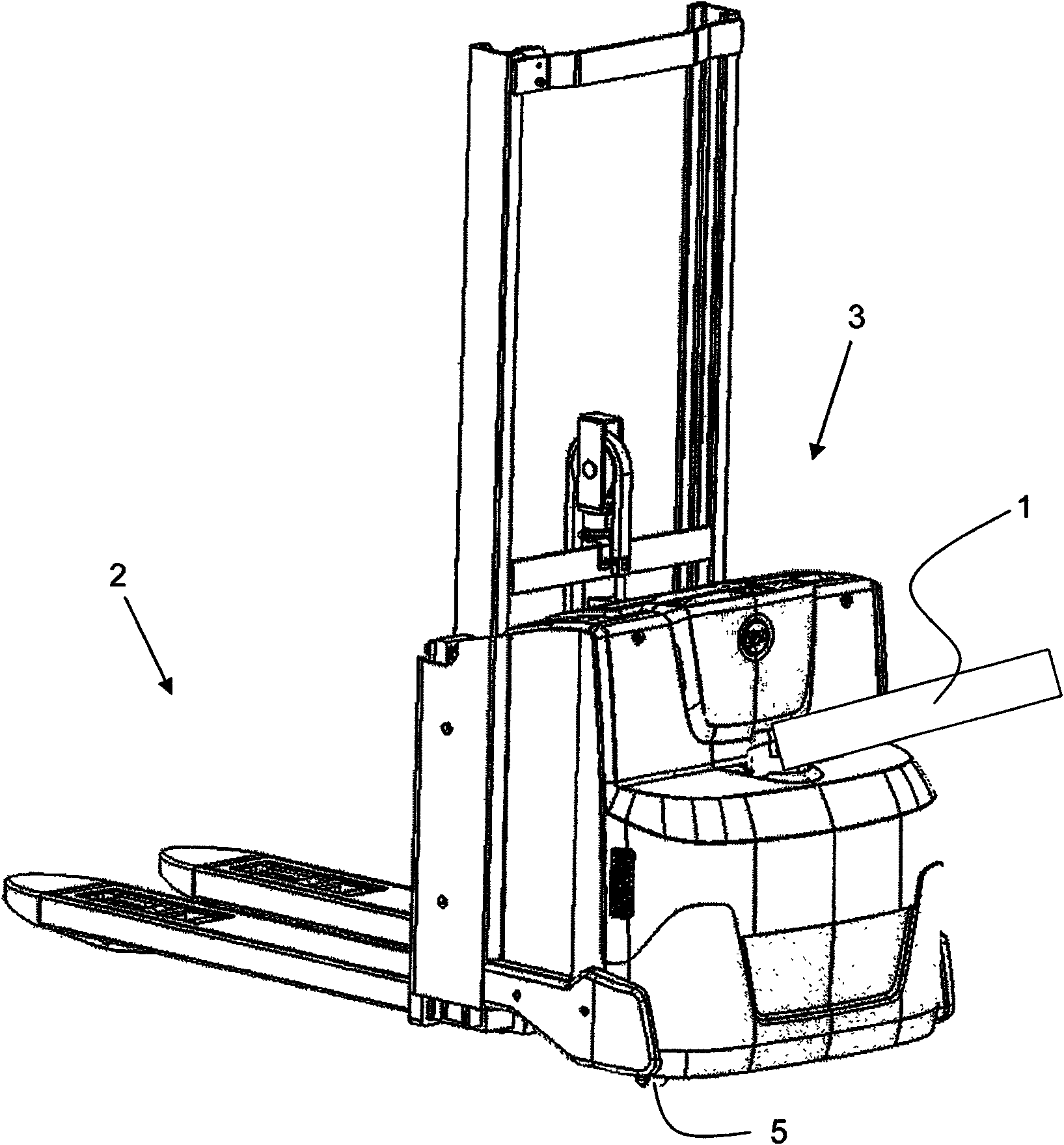

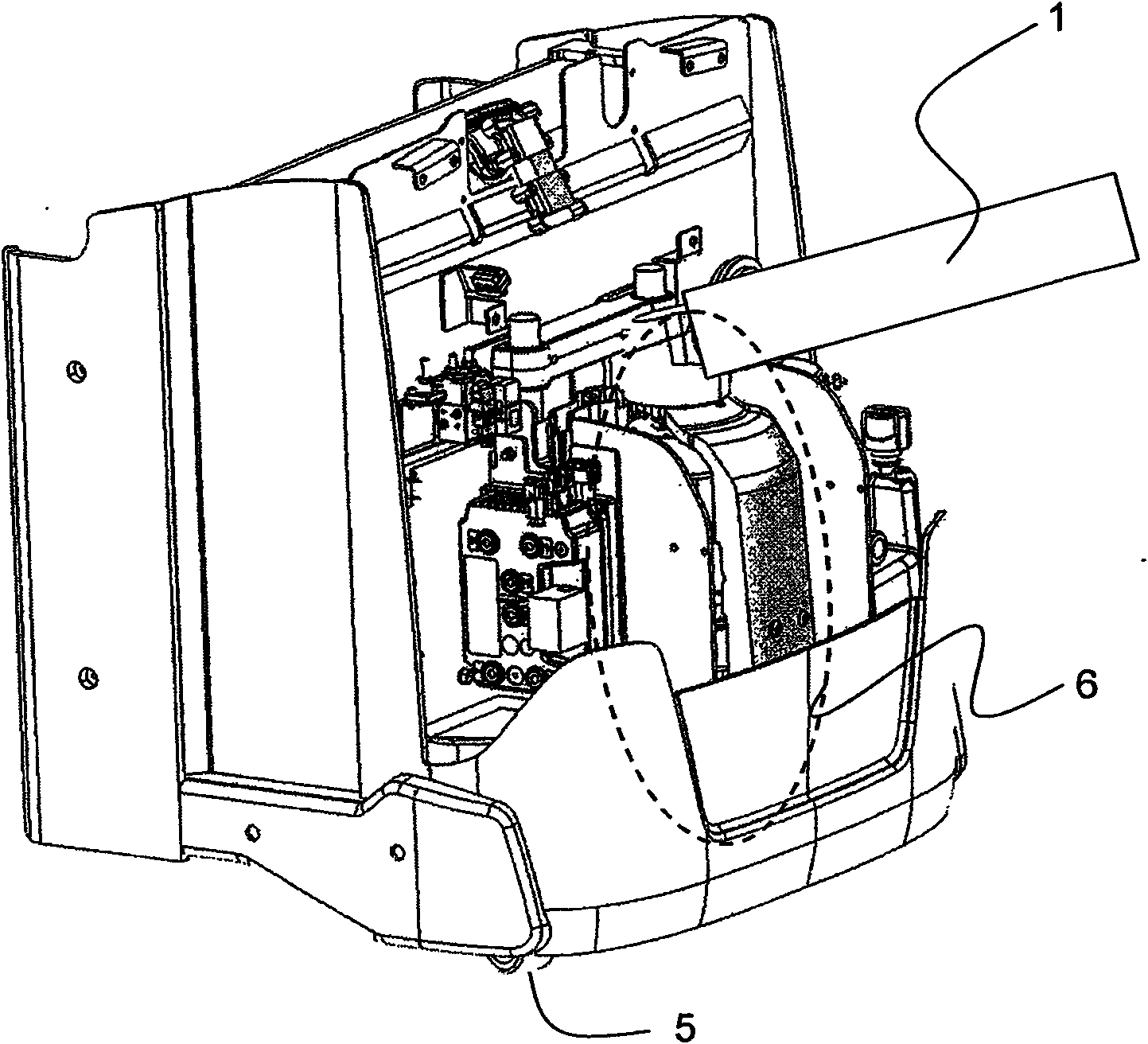

Floor conveying equipment especially fork load-unload car

ActiveCN1689957AShorten speedSuspension extension velocity attenuationLifting devicesResilient suspensionsDrive wheelTruck

The present invention relates to an earth-conveying equipment (1), especially a fork lift truck which comprises a driving part (2) and a bearing part (3), wherein, the area of the bearing part (3) is arranged with at least two bearing rollers (10), the area of the driving part (2) is arranged with at least one rotatable driving wheel (4) and at least one rotating roller (5a and 5b) which can rotate around one vertical axis and are arranged while the vertical movement is allowed and are supported by means of one spring shock absorbing device (12a and 12b). To improve the stability of the earth-conveying equipment the spring shock absorbing device (12a and 12b) comprises a shock absorbing device which functions when the rotating roller (5a and 5b) suspending protrudes and suspending retreat, especially a hydraulic shock absorbing device, and / or the spring shock absorbing device (12a and 12b) comprises a transition spring characteristic curve.

Owner:斯蒂尔公司

Operating apparatus for a working industrial vehicle

A two-way clutch is provided between an engine and a generator motor. Further, a battery and a cargo handling pump are provided. The generator motor is set to either a generator mode or an electric motor mode. When a cargo handling load (detected by a sensor) is small, the two-way clutch is set to a first state in which transmission of driving force from the engine to the generator motor is allowed and in which transmission of driving force in reverse is prevented. Further, when the engine is stopped or idled, the cargo handling pump is driven by the generator motor in the electric motor mode. When, during the above operation, the load increases to a level above a predetermined value, an increase in output of the generator motor and an increase in engine RPM are started, and when the engine RPM becomes equal to the RPM of the generator motor, which previously increased, the two-way clutch in the first state is connected, and the cargo handling pump is driven by the engine.

Owner:TOYOTA IND CORP

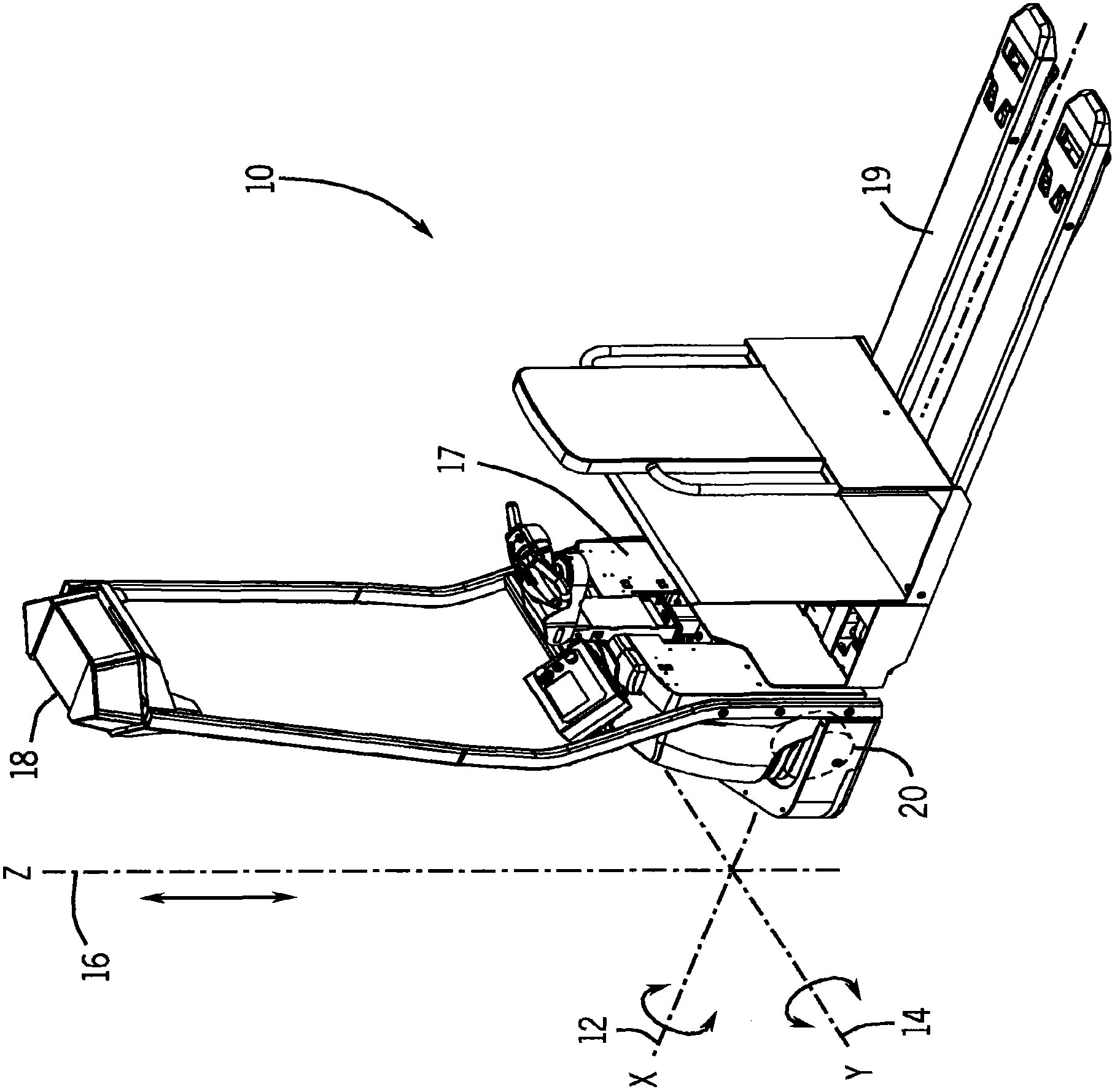

Dynamic Stability Control Systems and Methods for Industrial Lift Trucks

ActiveUS20120239259A1Reduce and eliminate motionOvercomes drawbackAnalogue computers for trafficSledge wheelsVibration controlControl system

A lift truck includes systems and methods for improved stability control. Stability control features reduce or eliminate motion of the truck in one or more of the X-axis, Y-axis, and Z-axis. Some embodiments may include, alone or in combination with the stability control, vibration control to further stabilize the motion of the truck.

Owner:RAYMOND LTD

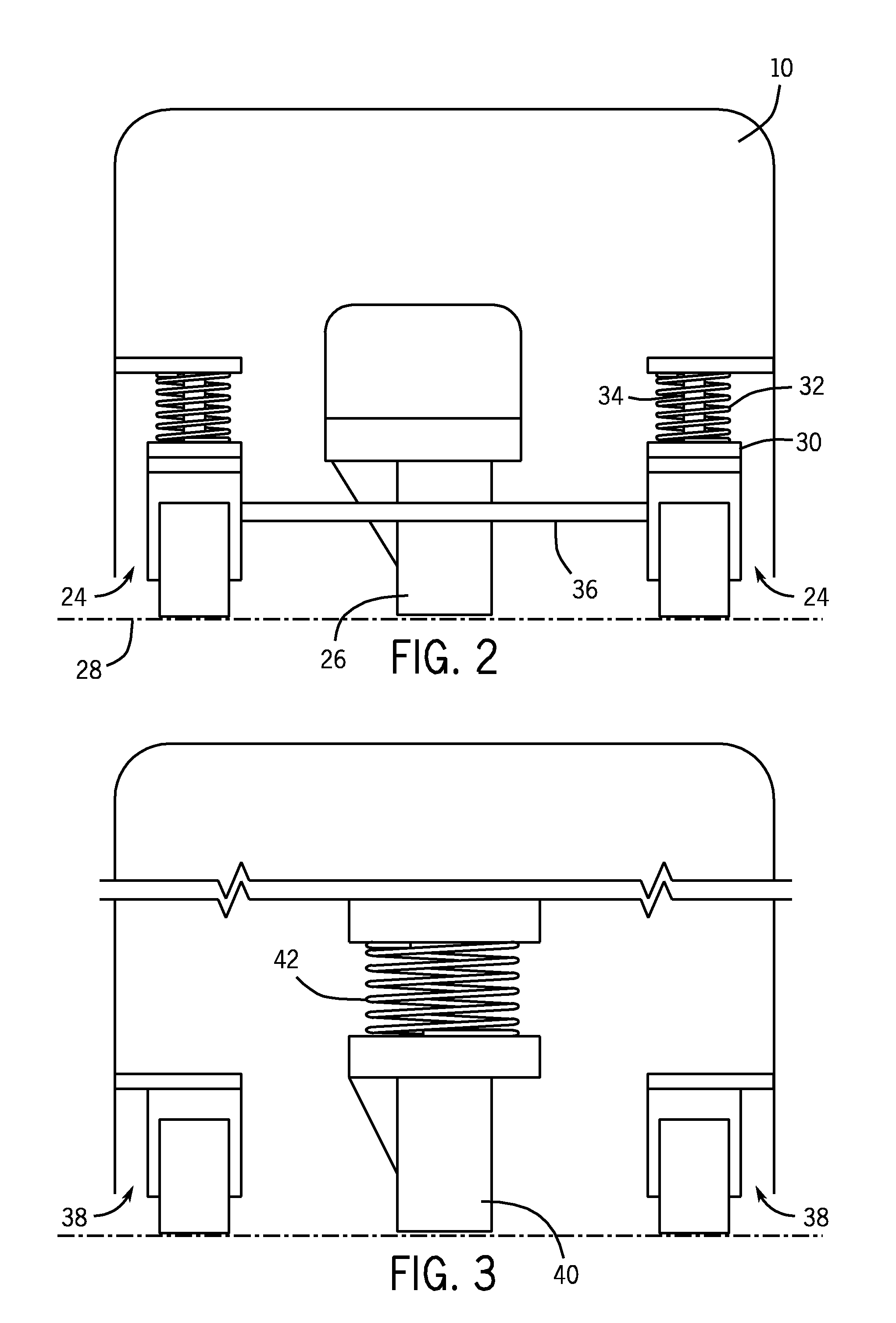

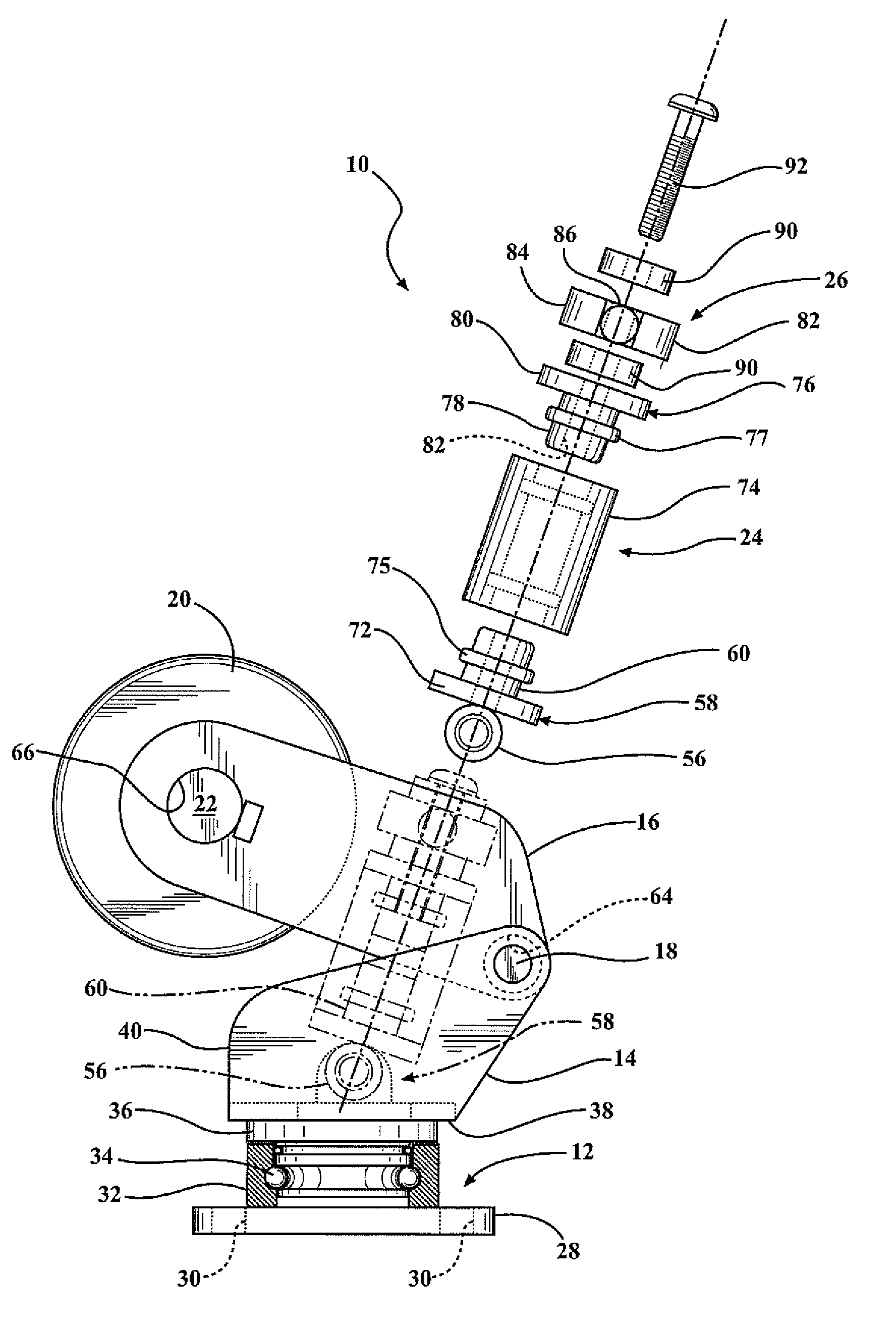

Vertically adjustable caster wheel apparatus

ActiveUS8839487B2Prevent movementSledge wheelsSprings/dampers design characteristicsEngineeringMaterial handling

A vertically-adjustable caster wheel apparatus for use on a forklift truck, material handling cart, and the like. The caster wheel apparatus of the present invention provides a yolk frame having a pivot pin connected to and extending through the yolk frame. A wheel frame has one end pivotally connected to the yolk frame and a second end rotatably connected to a wheel. An elastic member has a first retainer connected to one end of the elastic member and a second retainer connected to an opposite end of the elastic member, wherein the first retainer is connected to the pivot pin in the yolk frame to allow the elastic member to pivot with respect to the yolk frame. Means for adjusting the vertical height of the wheel is provided by adjusting the angle of the wheel frame relative to the yolk frame.

Owner:ROSS DESIGN & ENG

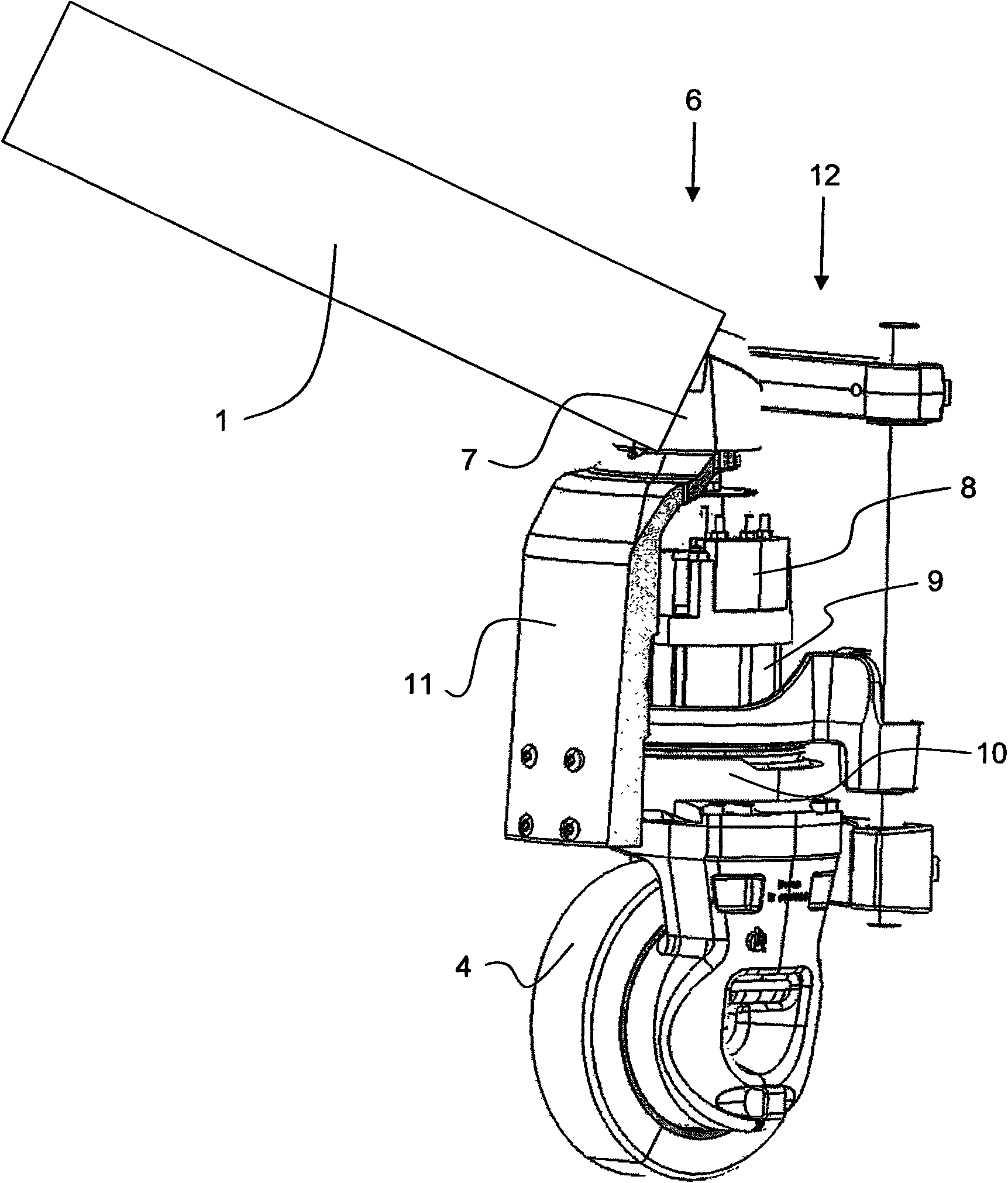

Industrial truck

ActiveCN102133848APrevent reboundImprove lateral stabilitySafety devices for lifting equipmentsSledge wheelsSteering wheelTruck

The present invention refers to an industrial truck comprising a suspension unit (12', 50) for a driving and steering wheel (4, 56). the industrial truck further has at least two side wheels (5). The truck further comprises restraining means (20) in engageable connection with the driving and steering wheel (4, 56), such that the restraining means (20) are capable of decreasing or stopping the vertical movement (V) of the driving and steering wheel (4, 56).

Owner:BT PROD

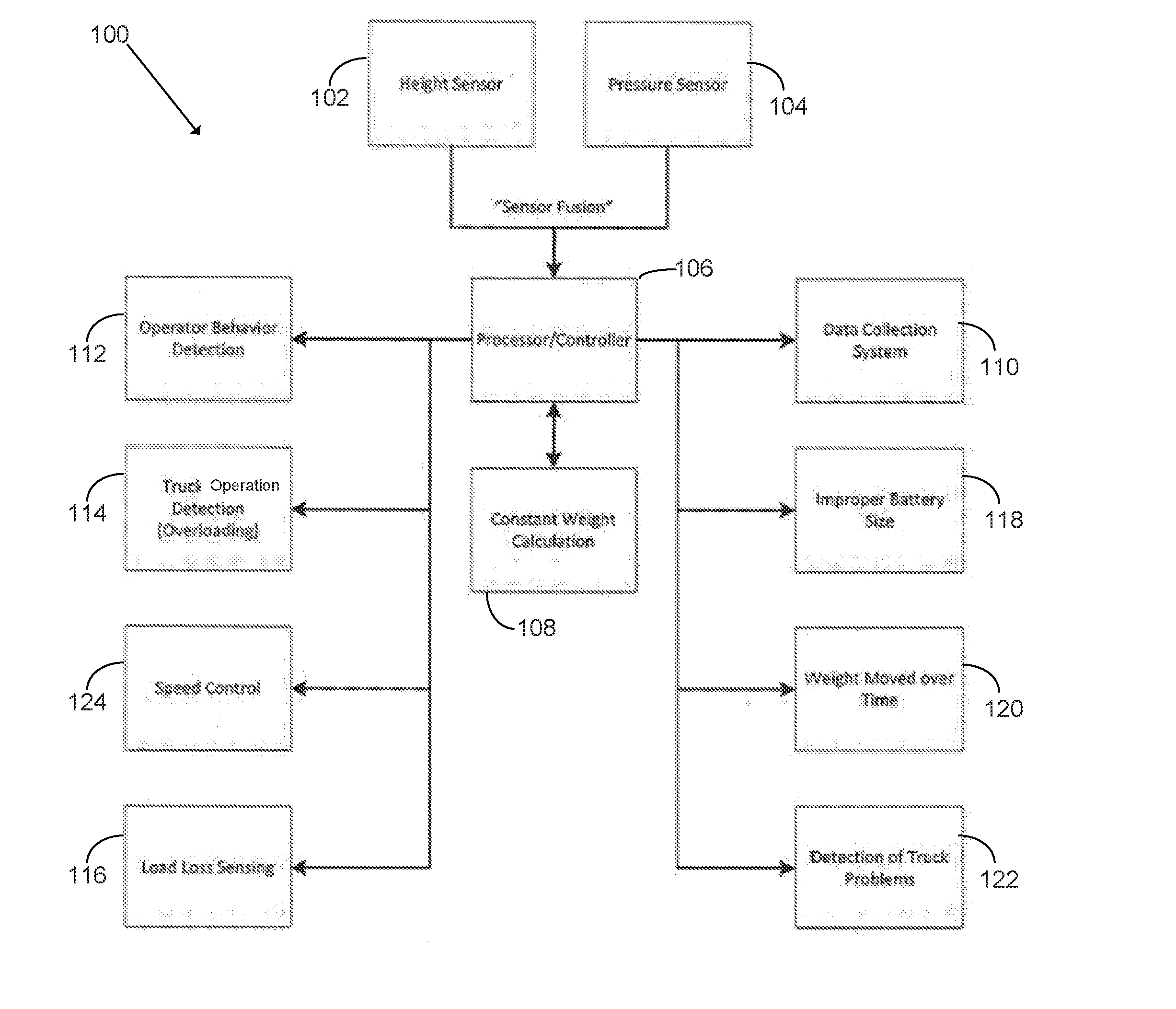

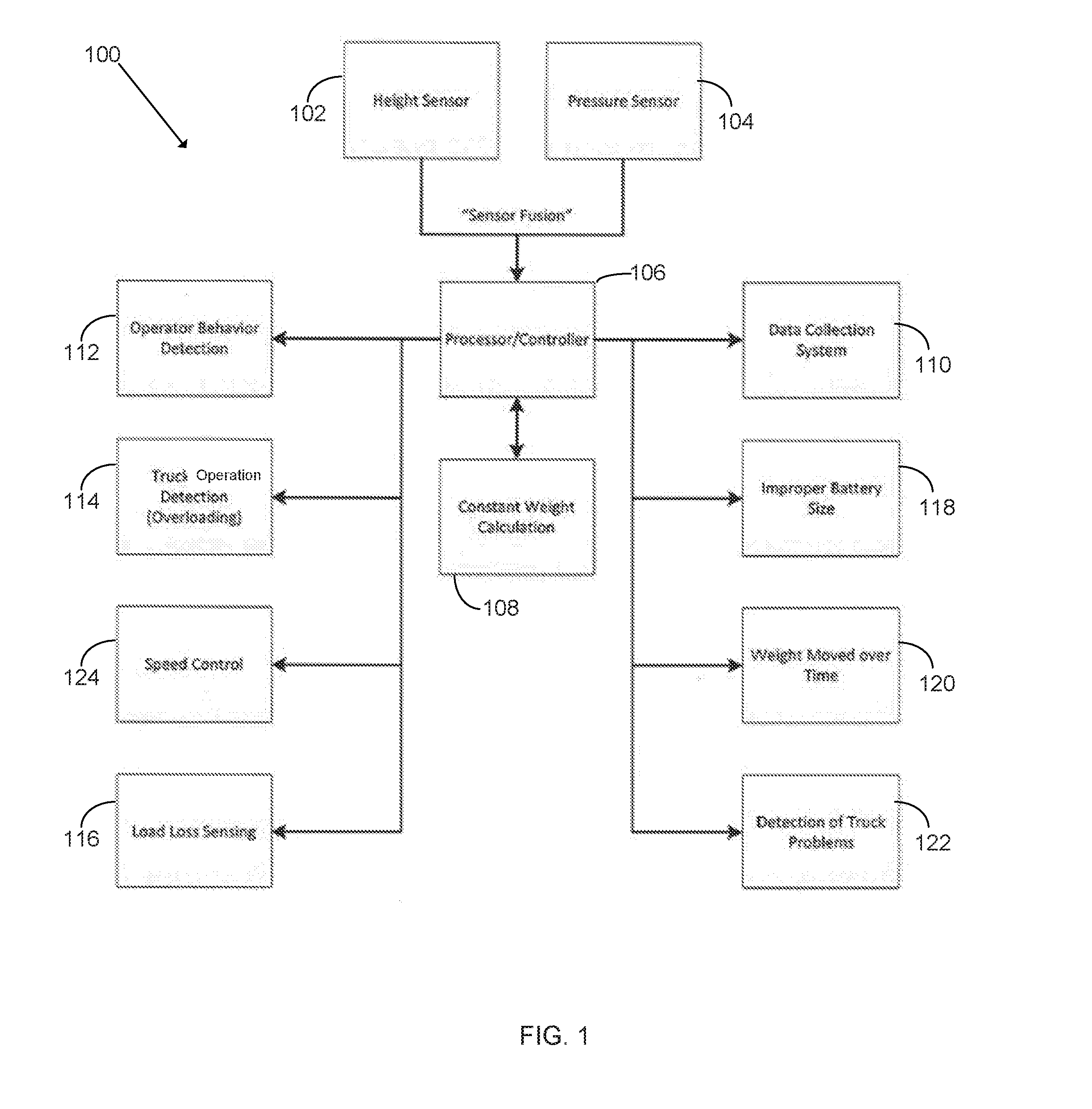

Systems and methods for weight determination and closed loop speed control

InactiveUS20160368493A1Safety devices for lifting equipmentsRegistering/indicating working of vehiclesControl systemClosed loop

A material handling vehicle control systems and methods comprise a plurality of sensors, the plurality of sensors coupled to a material handling vehicle; a data collection system; a processor, the processor executing a real time weight calculation program, the weight calculation program comprising the steps of receiving data from the plurality of sensors; and combining the data from the plurality of sensors to continuously determine a real time weight value of a load of the material handling vehicle; the processor controlling a speed of the material handling vehicle based on at least the real time weight value.

Owner:RAYMOND LTD

Dynamic Vibration Control Systems and Methods for Industrial Lift Trucks

ActiveUS20120235100A1Reduce and eliminate motionSmooth motionSafety devices for lifting equipmentsSpringsVibration controlControl system

A lift truck includes systems and methods for improved vibration control. Vibration control features reduce or eliminate motion of the truck in one or more of the X-axis, Y-axis, and Z-axis. Some embodiments may include, alone or in combination with the vibration control, stability control to further stabilize the motion of the truck.

Owner:RAYMOND LTD

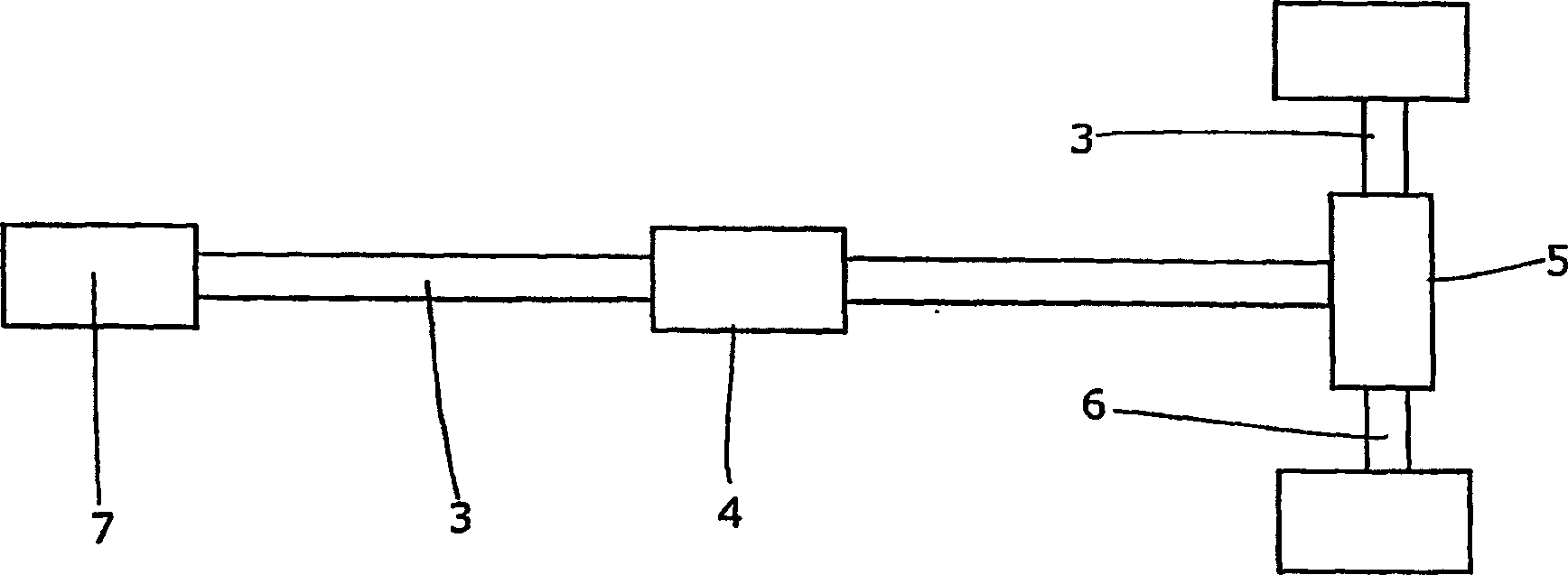

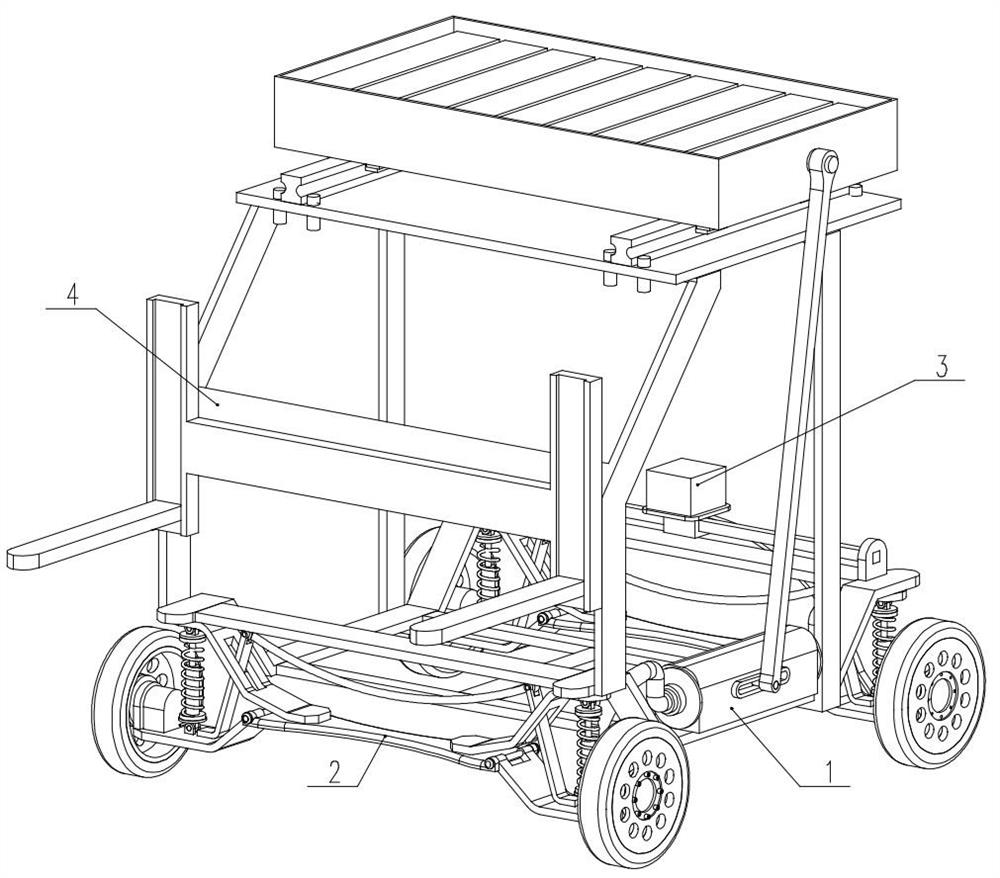

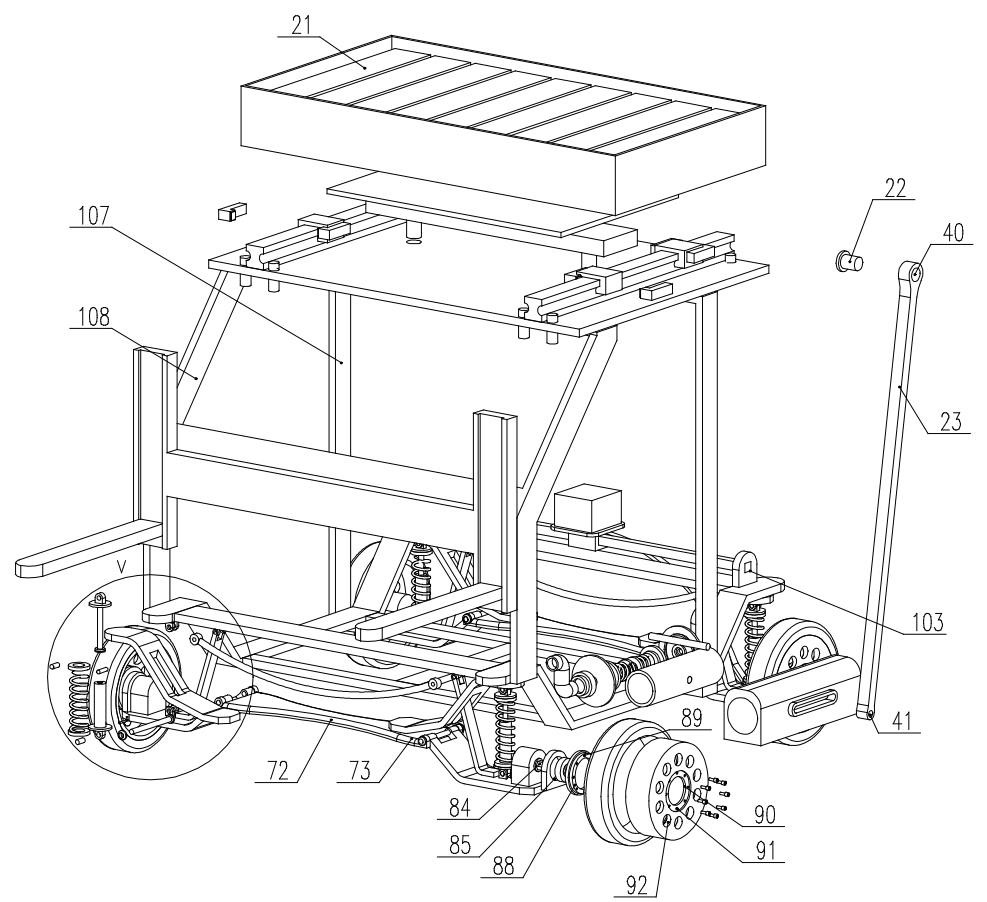

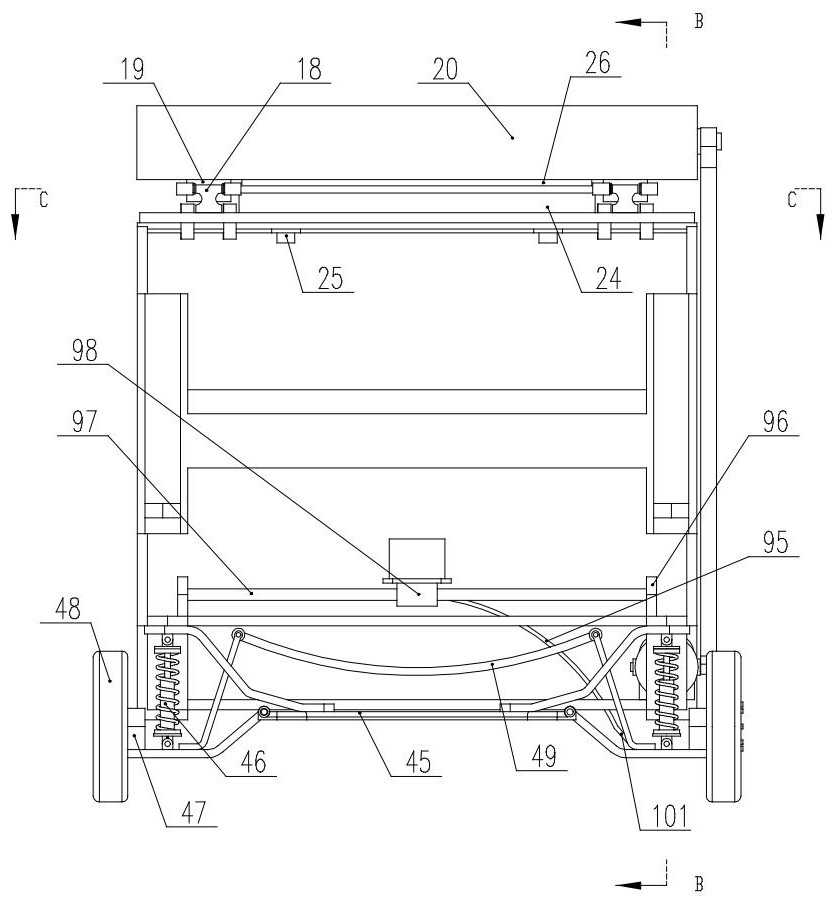

Counterbalanced forklift truck with automatic counterweight balancing function and using method thereof

ActiveCN113307185ASolving Elasticity ProblemsImplement automatic correctionVehicle body stabilisationLifting devicesVehicle frameGravity center

The invention discloses a counterbalanced forklift truck with an automatic counterweight balancing function. The counterbalanced forklift truck comprises a hydraulic self-driven counterweight balancing system, a wing type balancing semi-independent damping device, a lateral fine adjustment automatic balancing system and a forklift truck main body chassis frame system. The invention belongs to the technical field of carrying forklifts, and particularly relates to the counterbalanced forklift truck with the automatic counterweight balancing function and the using method thereof; and through the hydraulic self-driven counterweight balancing system and the lateral fine adjustment automatic balancing system, when goods are lifted or put down, the gravity center of a forklift truck is subjected to self-adaptive correction, the possibility that the forklift truck inclines forwards, backwards and laterally due to the fact that the offset of the gravity center is too large is greatly reduced, through the wing type balancing semi-independent damping device, the comfort and obstacle crossing ability of a forklift truck chassis are both considered, in-situ turning can be completed under the condition that an external structure is not added, the position of a weight box is locked through an electromagnetic weight box locking device after the gravity center is balanced, and the weight box is prevented from sliding over the limiting position through a thermal locking device at the end.

Owner:沛县汉方机械制造股份有限公司

Locking anti-motion suspension

ActiveUS7044482B2Effective lockingVehicle cleaning apparatusLoading/unloading vehicle arrangmentHydraulic cylinderHydraulic circuit

A skid steer vehicle has a suspension that includes a control arm pivotally coupled to the vehicle chassis that is supported by a hydraulic cylinder connected to an accumulator to provide springing. A hydraulic circuit coupled to the cylinder and accumulator permit the operator to raise and lower the chassis, to lock the suspension while the vehicle is loaded, and to automatically charge or discharge the accumulator to match the cylinder pressure during loading and unloading. In this manner, when the suspension is unlocked after loading, the vehicle chassis neither rises nor falls.

Owner:CNH IND AMERICA LLC +1

Industrial vehicle

ActiveUS20150094936A1Improve efficiencyImprove maximizationAnalogue computers for vehiclesProgramme-controlControl theory

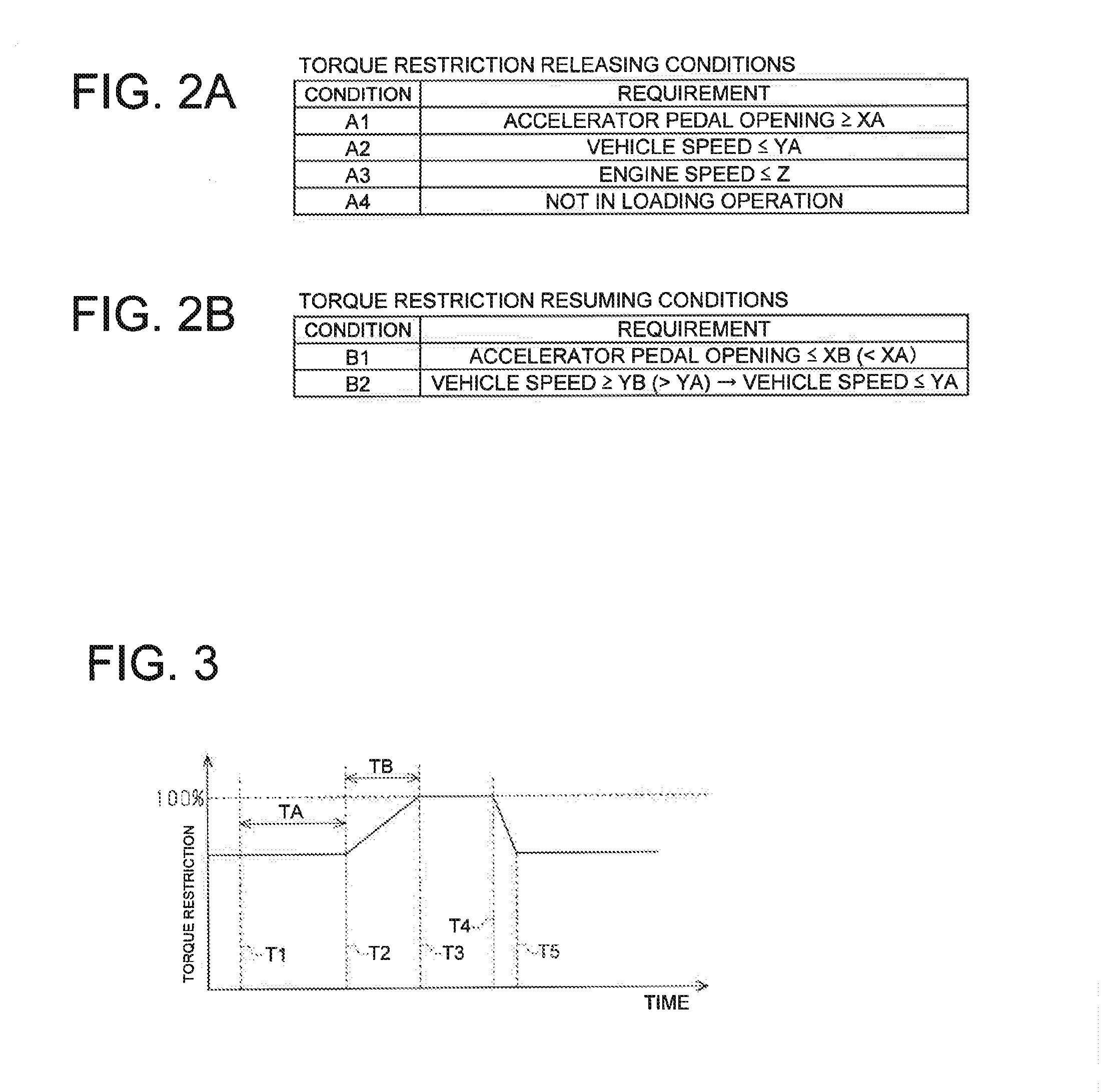

An industrial vehicle which is equipped with an engine and having an Eco-mode in which torque of the engine is restricted includes an accelerator, an accelerator opening detector that detects an opening of the accelerator, a vehicle speed detector that detects a speed of the vehicle, an engine speed detector that detects a speed of the engine, and a torque restriction releasing unit which, when the torque of the engine is restricted, if conditions that the opening of the accelerator detected by the accelerator opening detector is a first predetermined value or greater, that the vehicle speed detected by the vehicle speed detector is a second predetermined value or smaller and that the engine speed detected by the engine speed detector is a third predetermined value or smaller are satisfied, releases the torque restriction.

Owner:TOYOTA IND CORP

Dynamic vibration control systems and methods for industrial lift trucks

A lift truck includes systems and methods for improved vibration control. Vibration control features reduce or eliminate motion of the truck in one or more of the X-axis, Y-axis, and Z-axis. Some embodiments may include, alone or in combination with the vibration control, stability control to further stabilize the motion of the truck.

Owner:RAYMOND LTD

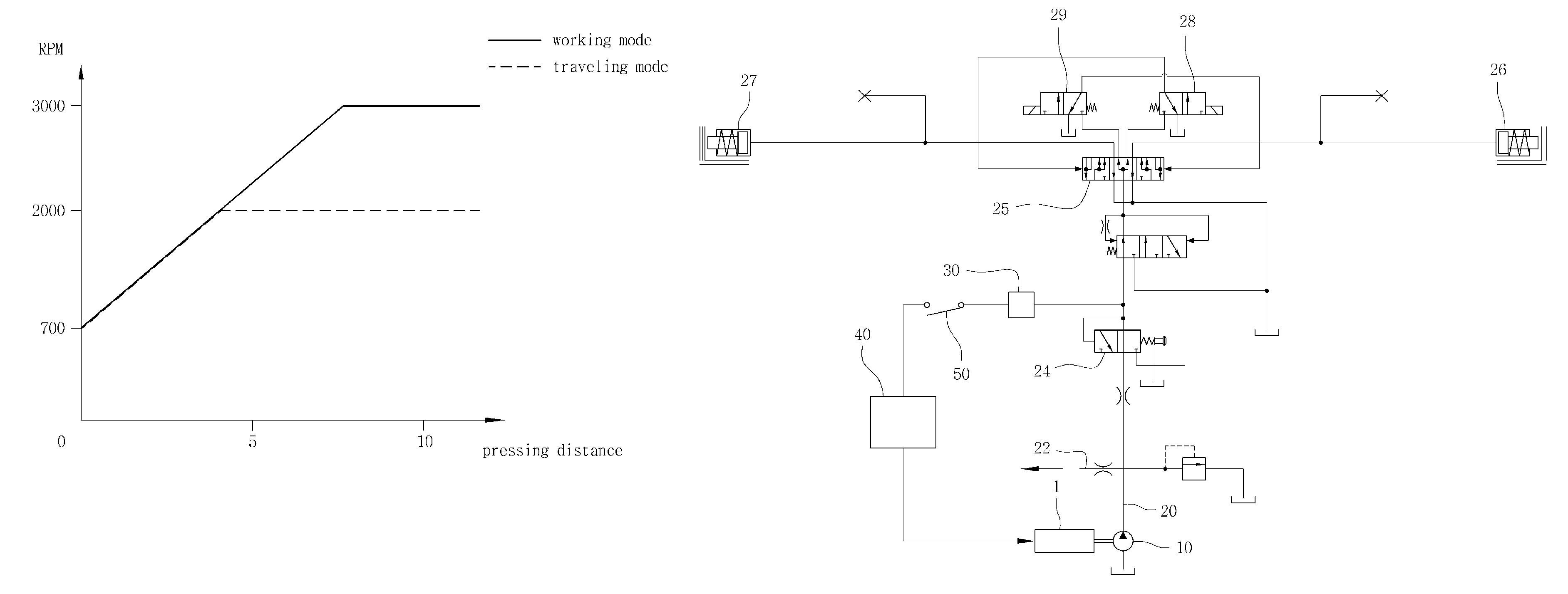

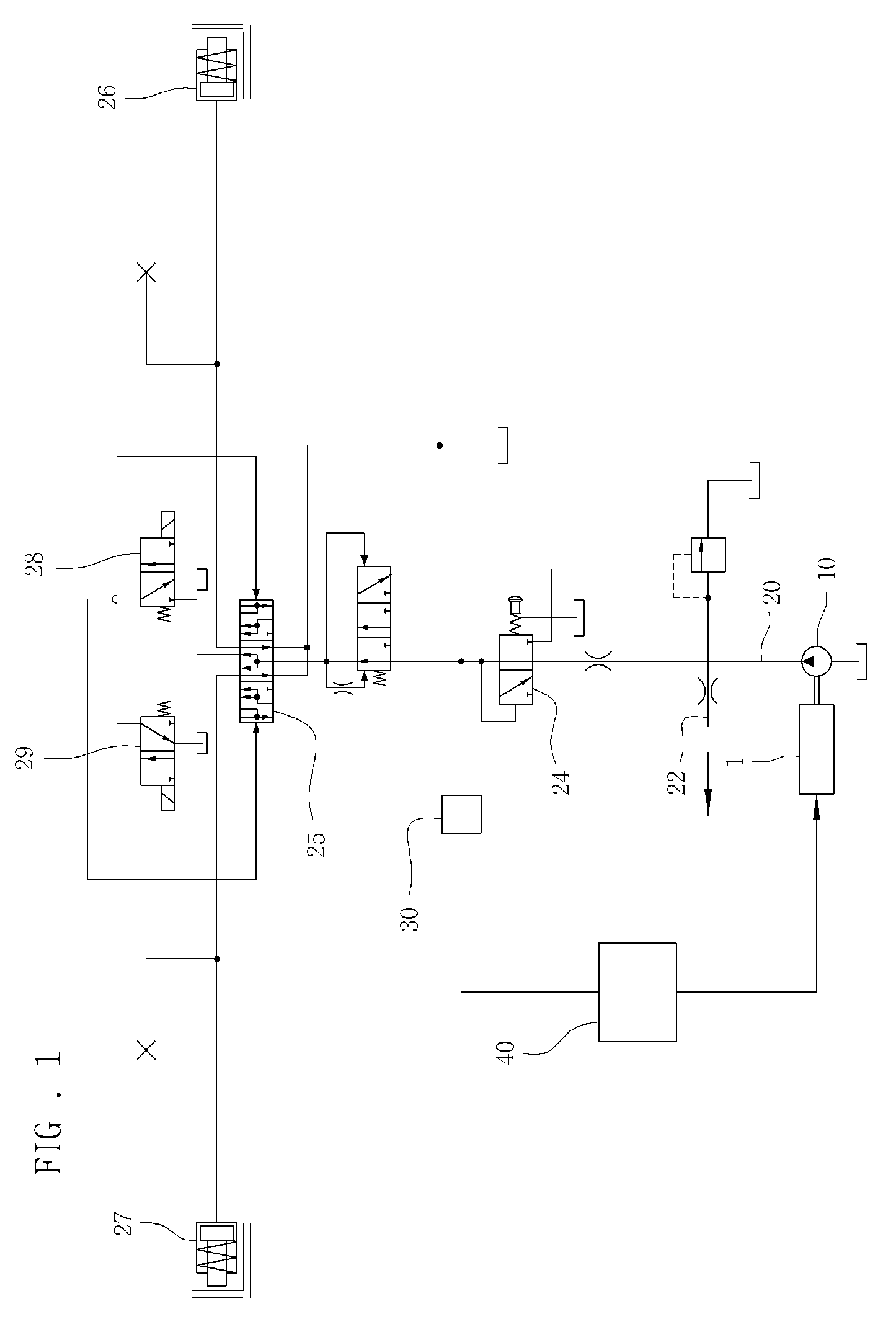

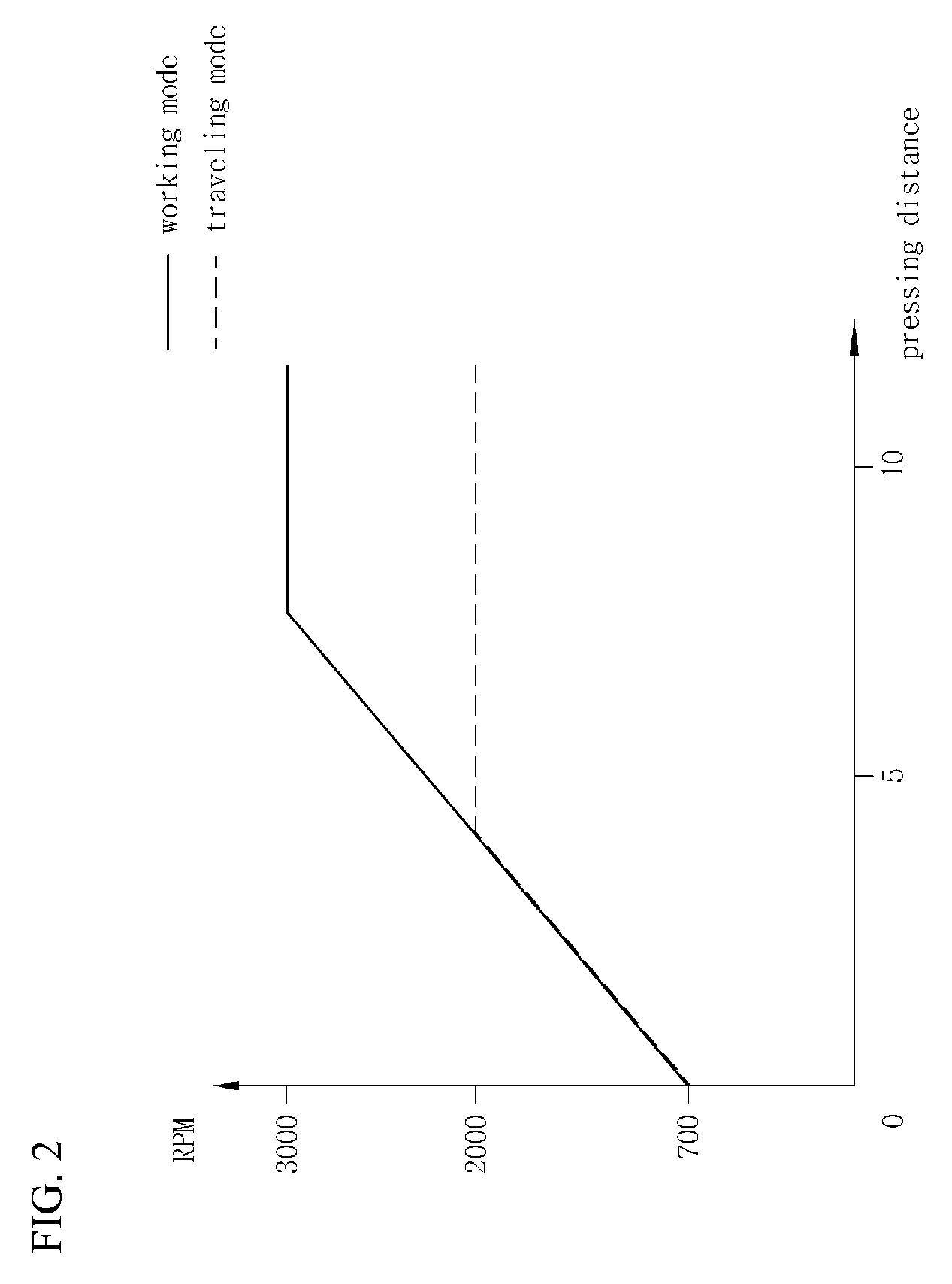

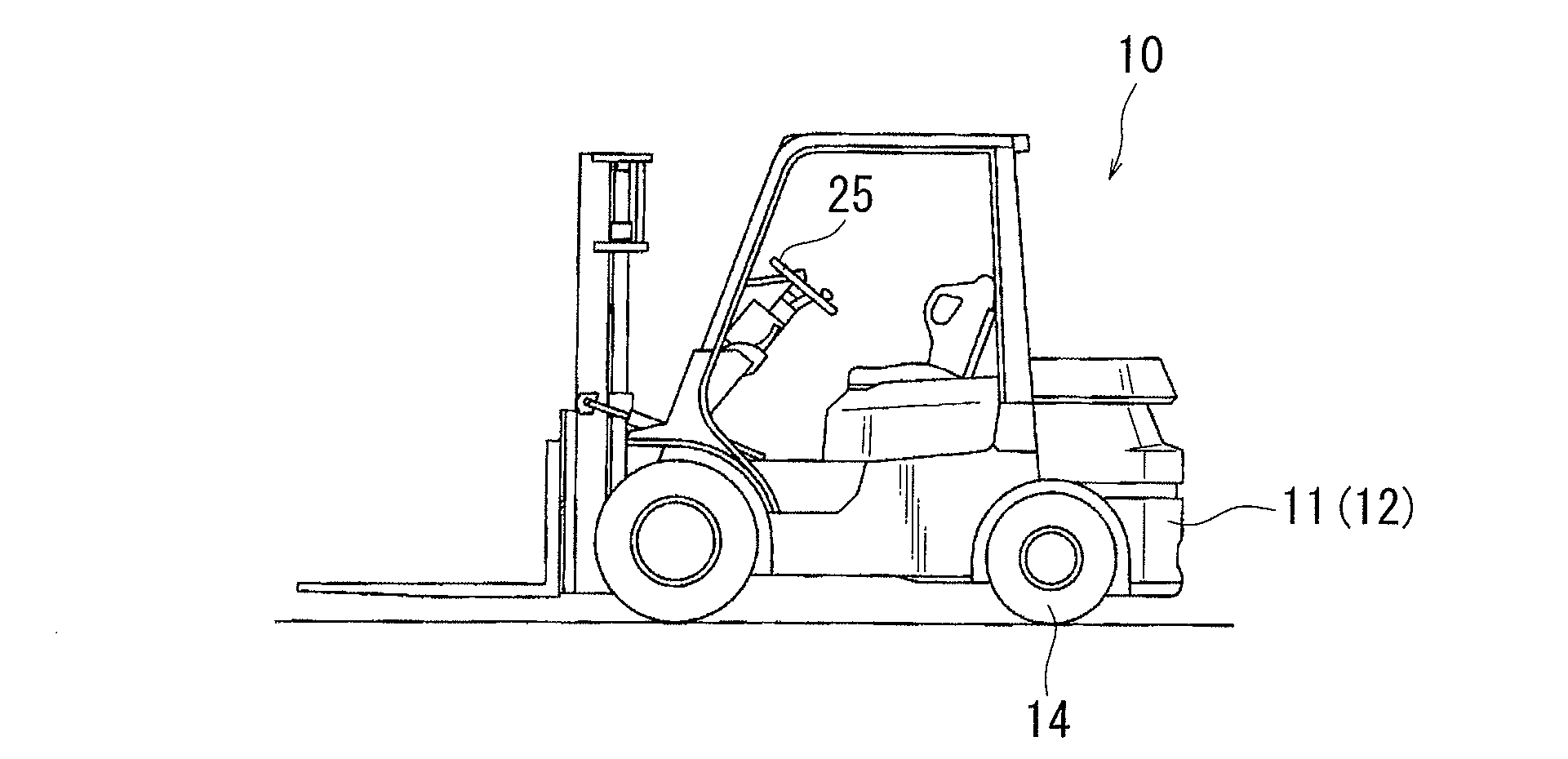

Control apparatus for engine-powered forklifts

ActiveUS7716926B2Guaranteed uptimeAvoid safety hazardsFluid couplingsGearing controlTravel modeControl theory

Owner:DOOSAN IND VEHICLE

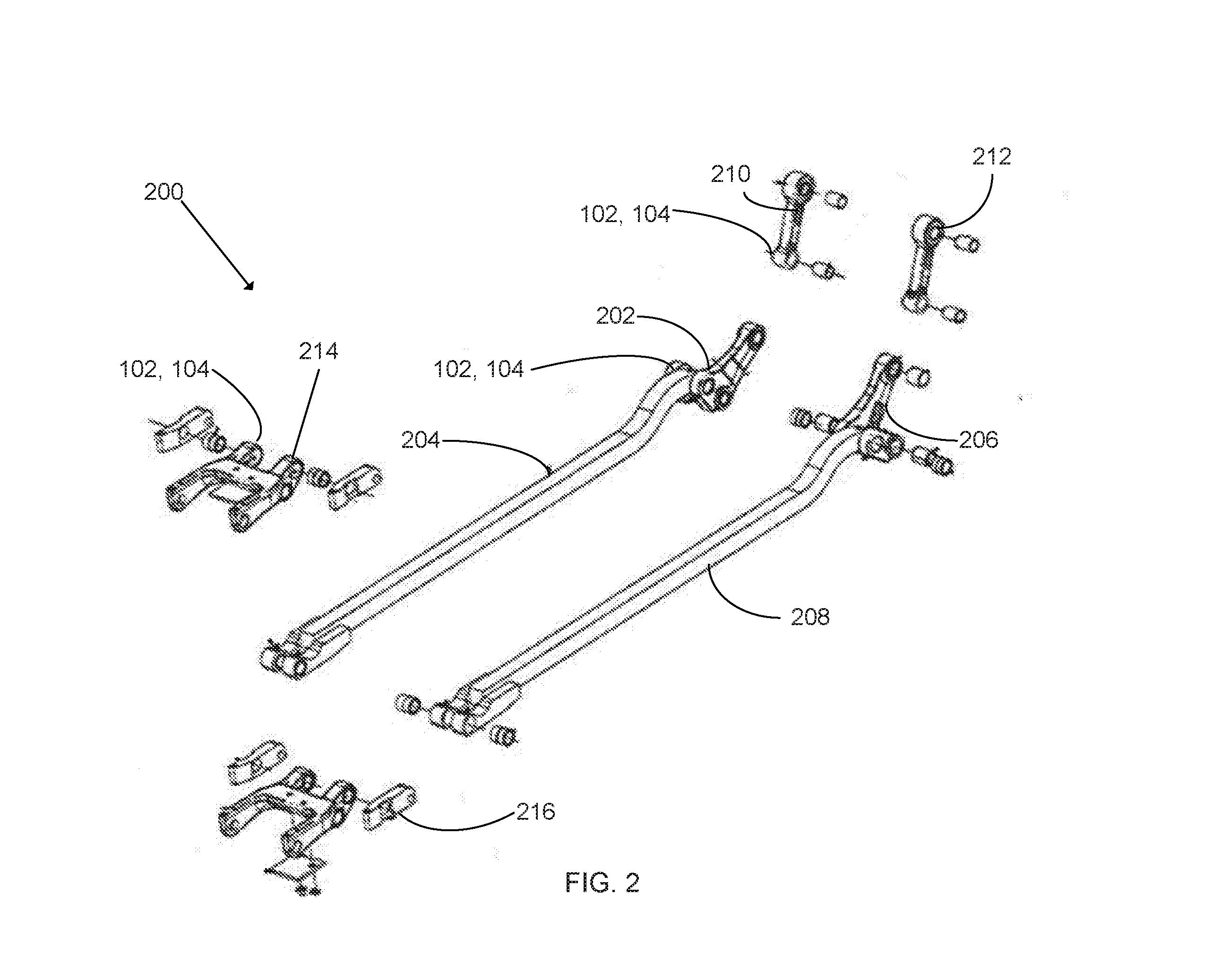

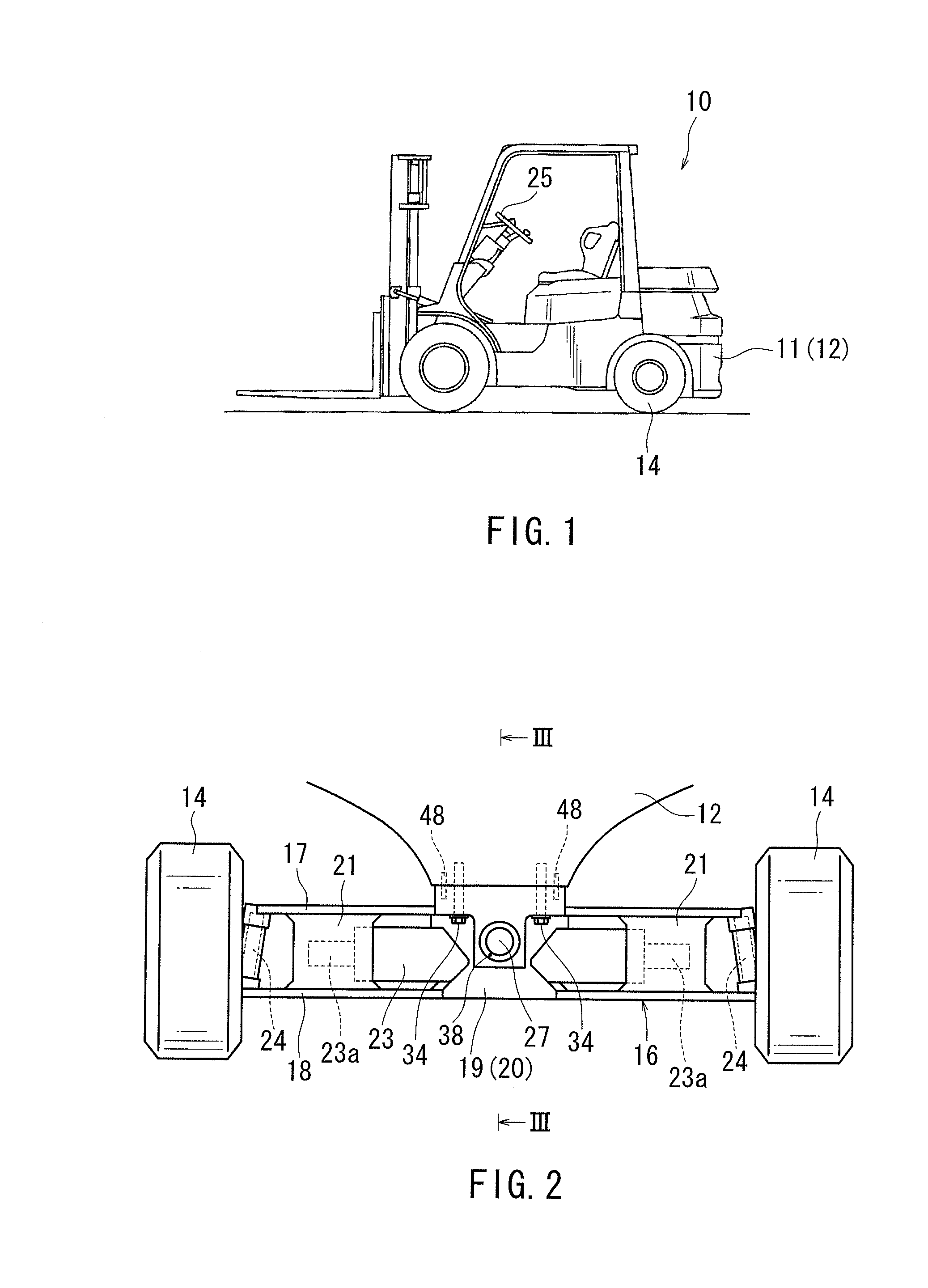

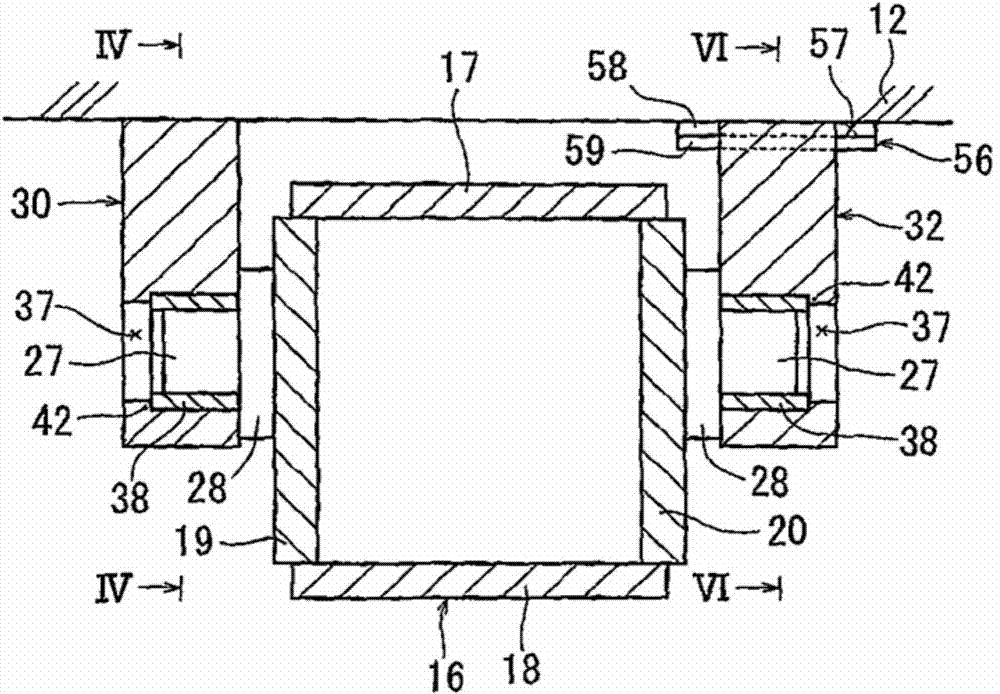

Axle support structures for industrial vehicles

ActiveUS20140145409A1Shorten production hoursEasy to disassembleRigid suspensionsResilient suspensionsEngineering

Owner:TOYOTA IND CORP

Axle support structures for industrial vehicles

ActiveCN103802624AEasy to removeRigid suspensionsResilient suspensionsWheel and axleAutomotive engineering

Owner:TOYOTA IND CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com