Improvements in or relating to fork lift trucks

A forklift and wheel technology, applied in the field of height measurement system, can solve problems such as high cost, time-consuming, and system cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

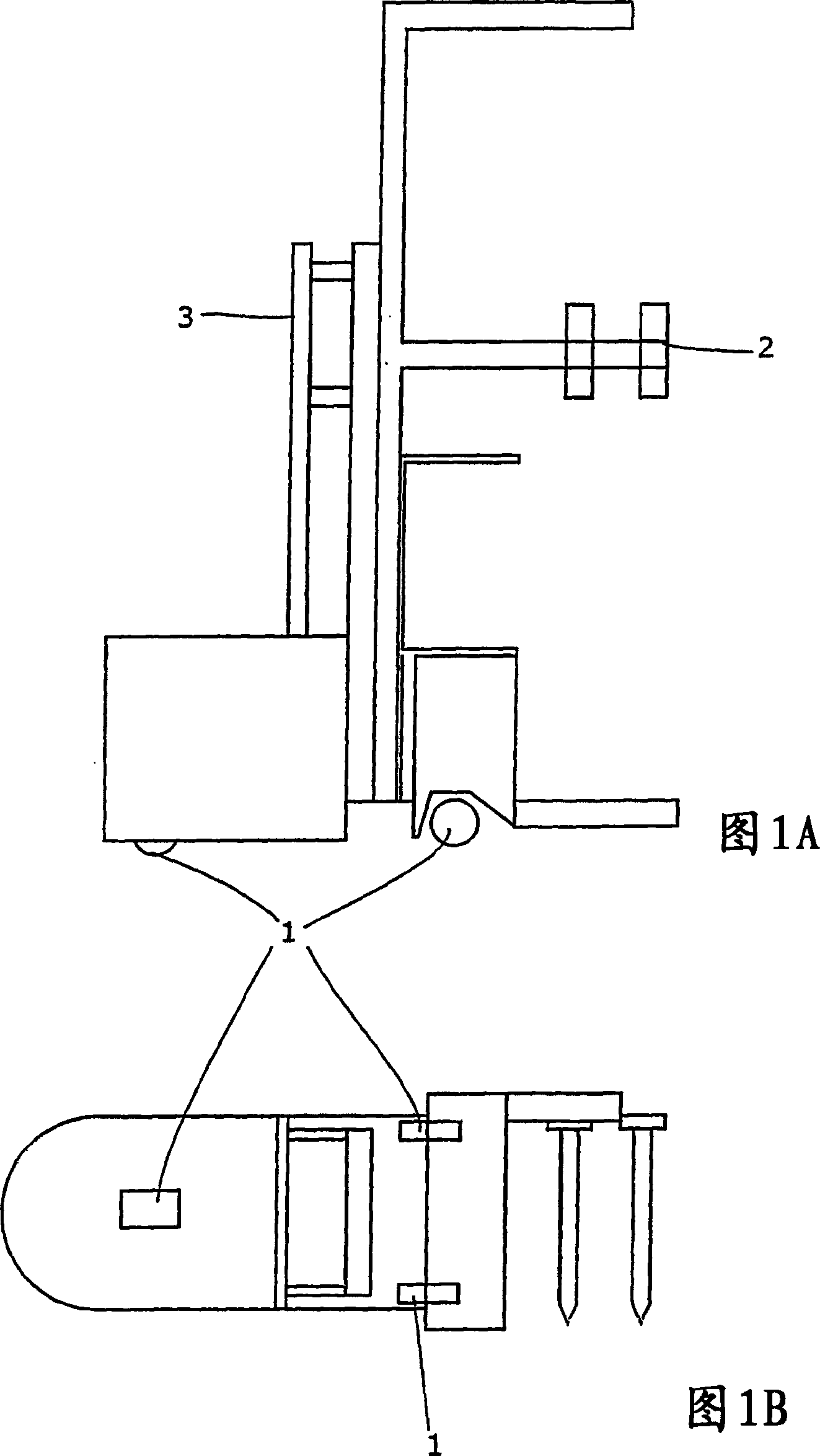

[0029] Referring to Figures 1A and 1B, a conventional forklift assembly is shown supported on wheels 1. The chassis is a rigid structure, and the wheels are not equipped with suspension devices. The fork 2 can be raised together with the mast 3 of the forklift to reach a higher position.

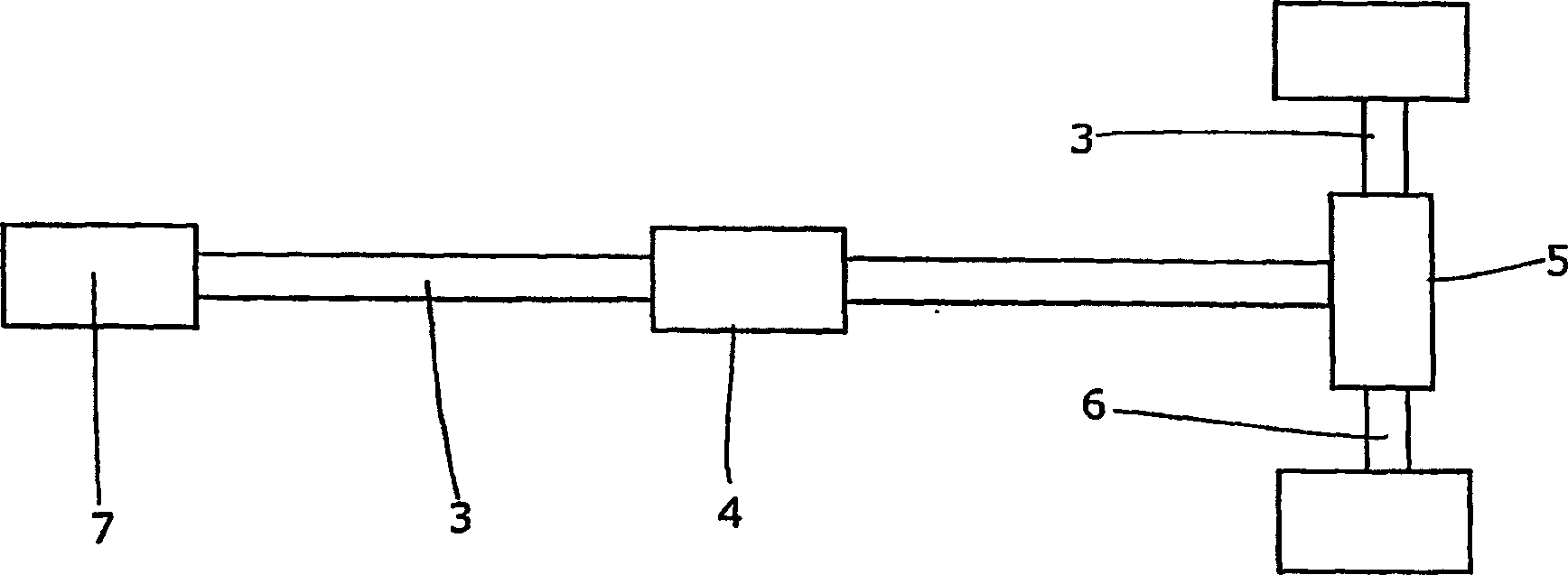

[0030] figure 2 It is a simplified plan view of the chassis 3 of a forklift according to one embodiment of the present invention. A plurality of sensors 4 are fastened to the chassis and are able to derive the height difference between the front and rear axles 6 and 7 . Furthermore, a sensor 5 is fastened to the chassis axle 6 between the right and left wheel tracks in order to be able to derive the height difference between the front wheels 1 .

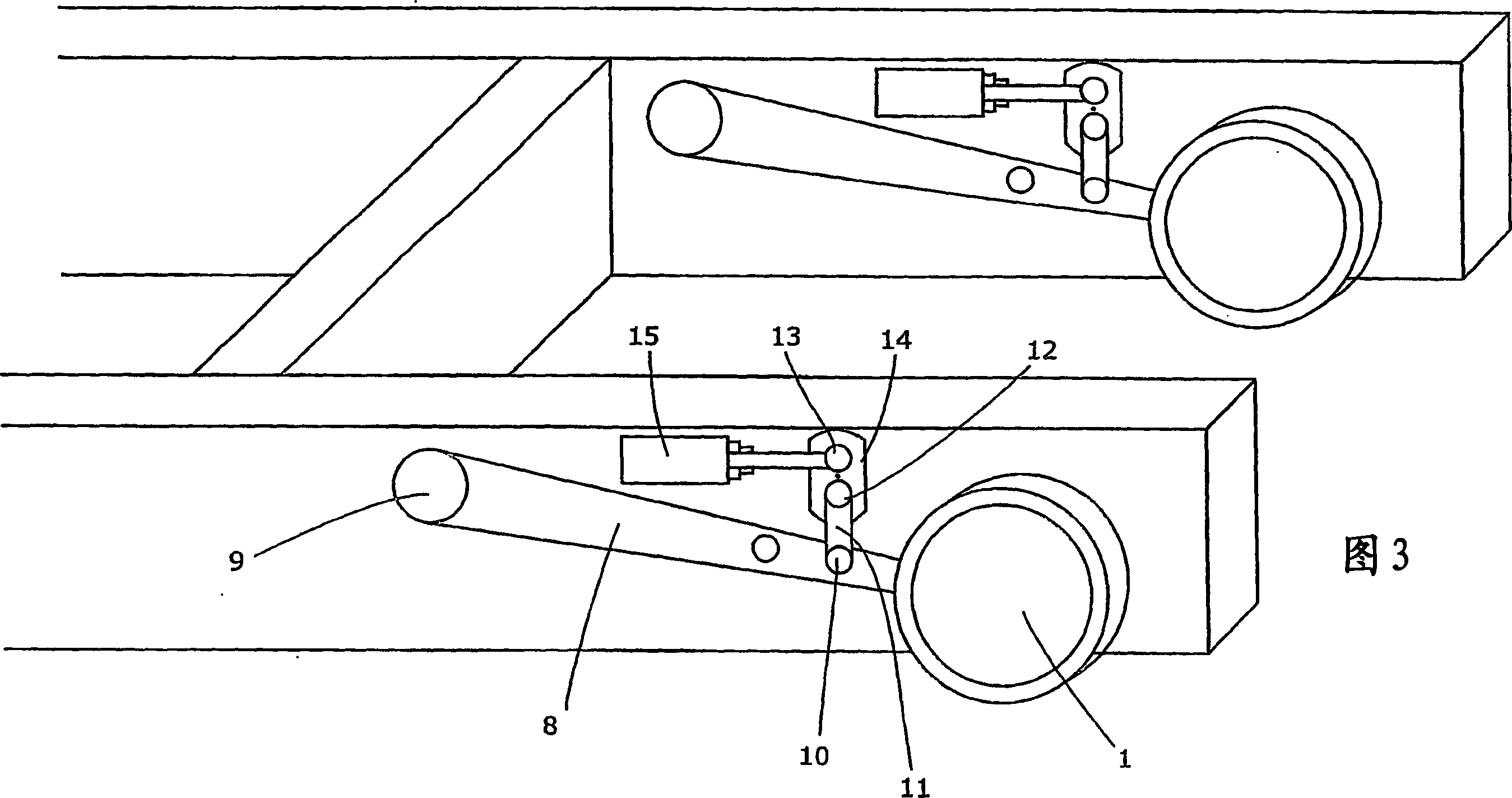

[0031] Figure 3 is a view of the support arm supporting the front wheel of the forklift. The front wheels 1 are supported on the cantilever 8, and the cantilever 8 is fixed to the chassis of the forklift truck through the pivot bearing 9, so th...

example 2

[0037] In another embodiment as shown in FIGS. 4A and 4B , the lift truck is provided with a memory unit in which data corresponding to changes in the roughness of the road surface to be traveled can be stored. When the forklift is traveling on such a route, the forklift is automatically raised hydraulically to compensate for changes in levelness by sending a signal from the memory to the hydraulic pistons that connect the front wheel unit of the forklift to the body of the vehicle. Together. In this way, even when traveling on a surface with varying degrees of flatness relative to the horizontal plane, the forklift truck can still transport loads along the route safely and stably, for example in a corridor between two racking units.

[0038] In this embodiment, the forklift has two special components, namely: an electronic profiler capable of recording surface irregularities and an active suspension unit which can be operated with suitable algorithms, to compensate for surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com