Dynamic vibration control systems and methods for industrial lift trucks

一种振动控制、叉车的技术,应用在非旋转振动抑制、叉车、手推车等方向,能够解决限制弹簧脚轮配置性能表现、没有考虑是否倾斜叉车、移动固定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

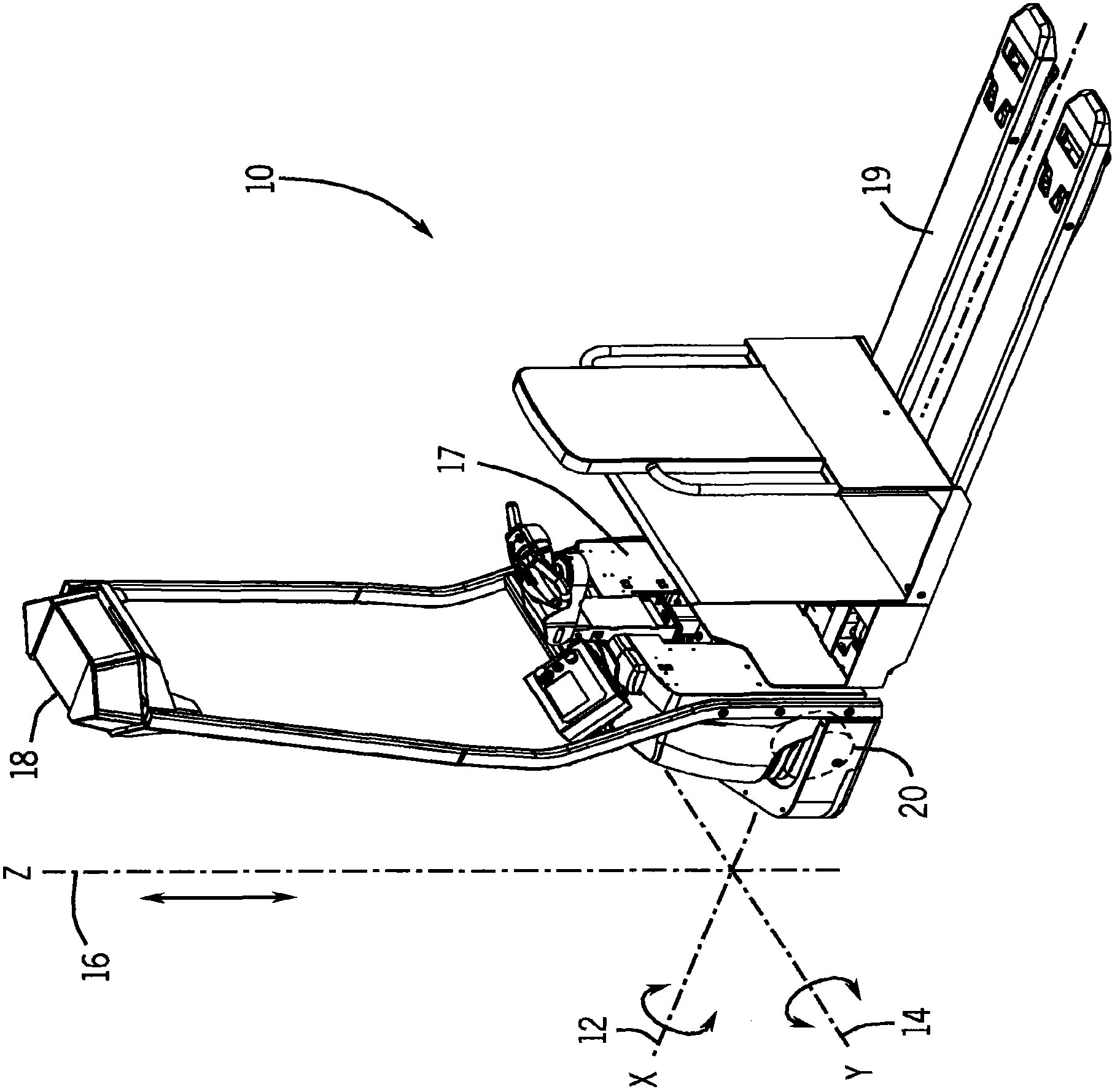

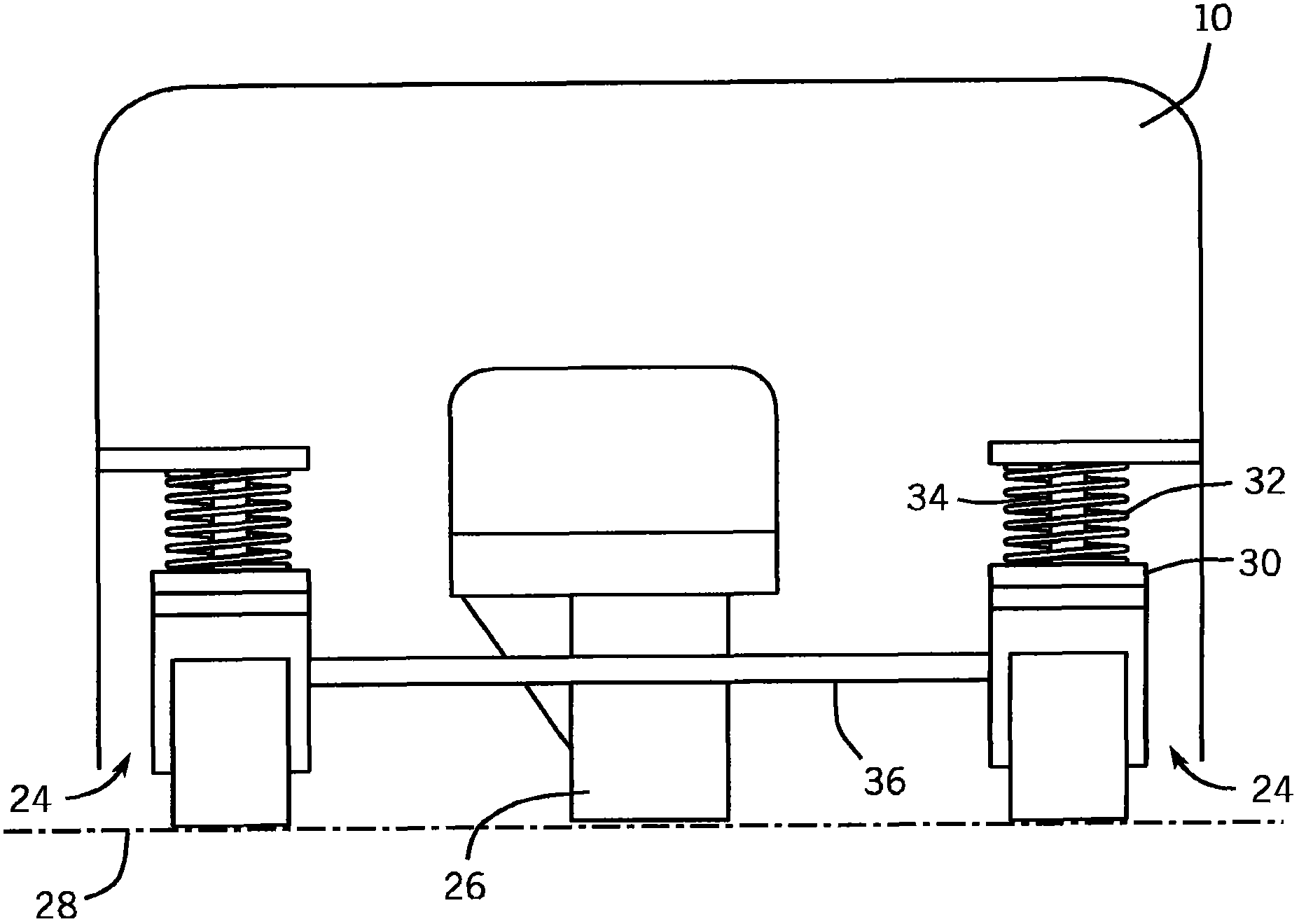

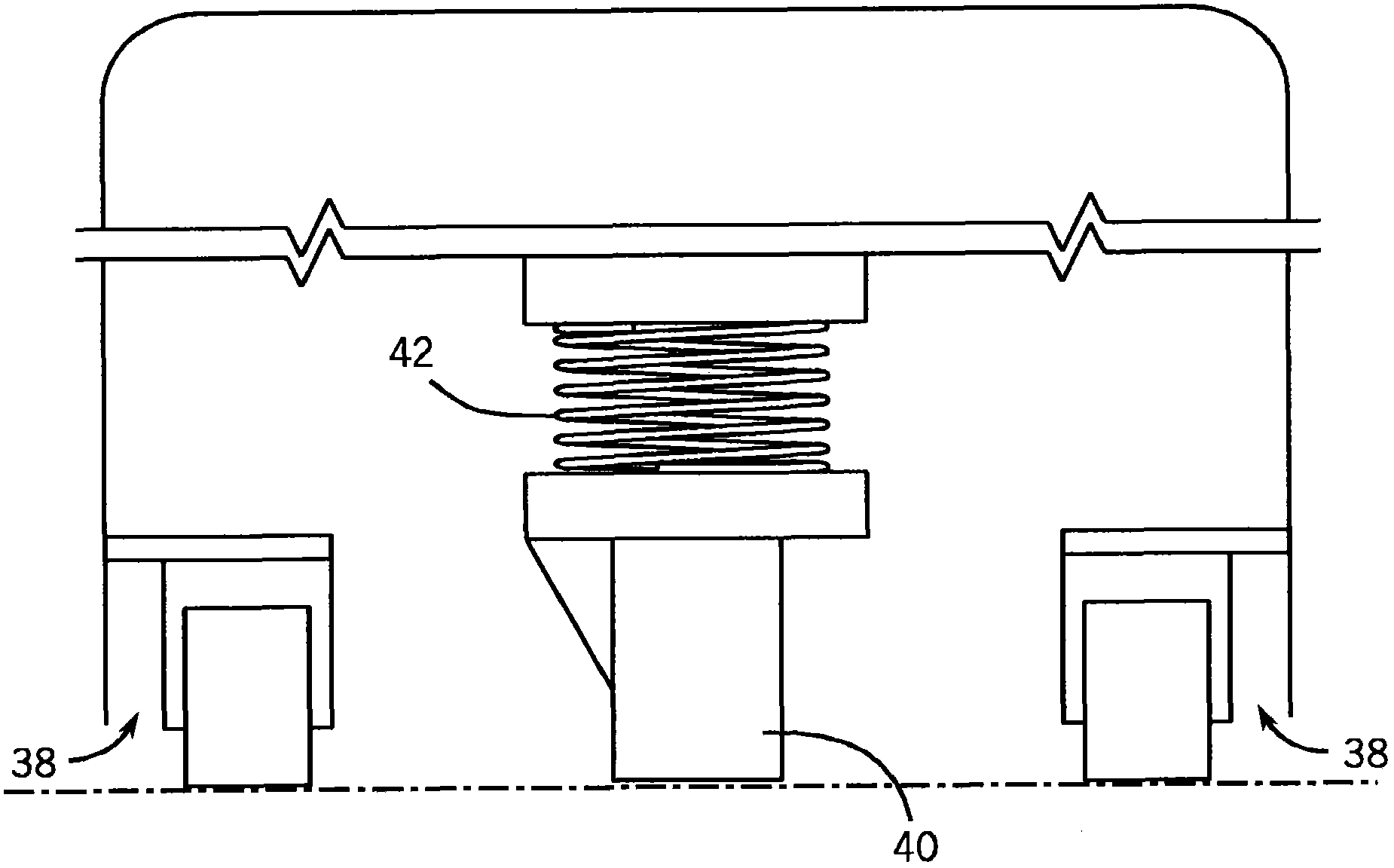

[0030]Various aspects of the invention are described below in connection with improving the stability and vibration control of industrial forklifts. This is because the features and advantages arising from the embodiments of the present invention are well suited for this purpose. Still, it should be appreciated that aspects of the invention may also be used to achieve other objectives.

[0031] Embodiments of the invention described herein, alone or in combination, are suitable for providing dynamically stable forklifts, including, for example, dual-purpose vehicles that can be operated as autonomous robotic vehicles and also as a standard manually-operated forklift forklift. The forklift is stabilized by one or more individual or combined improvements configured to effect motion in any of the three axes and, in some embodiments, coupled with vibration damping. These combined improvements provide protection for sensitive electronic components, increase operator comfort and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com