Floor conveying equipment especially fork load-unload car

A technology for ground transportation and loading and unloading trucks, which is applied to forklifts, transportation and packaging, and motor vehicles. It can solve the problems of poor stability of ground transportation equipment and achieve high reliability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

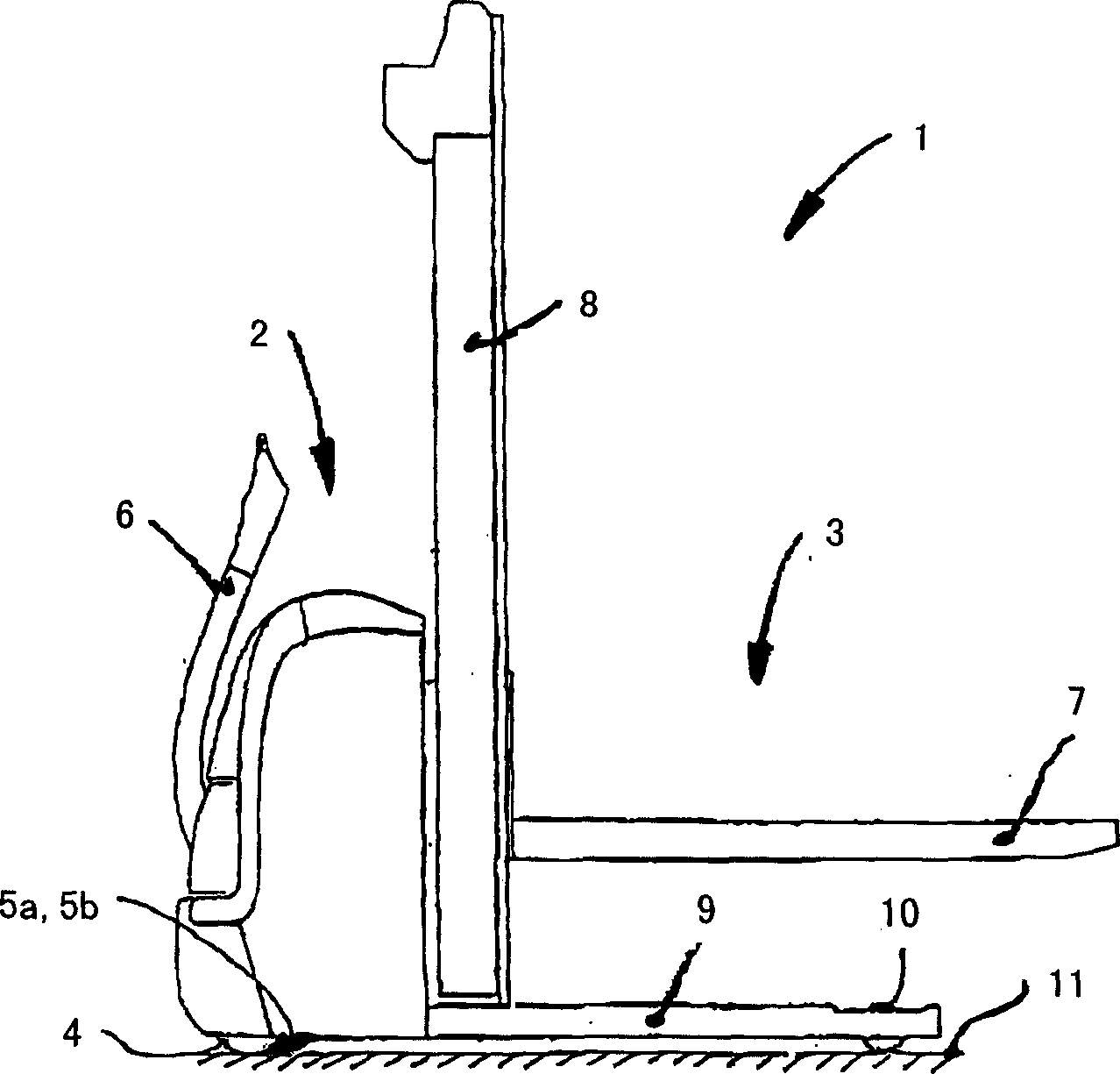

[0029] figure 1 A floor conveying device 1 constructed as a high-lift forklift truck towed by a drawbar is given in , which includes a drive part 2 and a load-carrying part 3 . The drive part 2 has a drive wheel 4 arranged centrally with respect to the longitudinal axis of the floor conveyor 1 and two turning rollers 5a, 5b arranged laterally. The drive wheel 4 can be guided by means of a drawbar 6 . The carrying part 3 includes a carrying arm 7 which is arranged on the lifting device 8 and can move up and down. The carrier part 3 also includes two spokes 9 , each of which accommodates a carrier roller 10 configured as a simple roller or a tandem roller. The floor conveyor 1 is thus supported on the running rail 11 by means of the drive wheels 4 , the turning rollers 5 a , 5 b and the carrier rollers 10 .

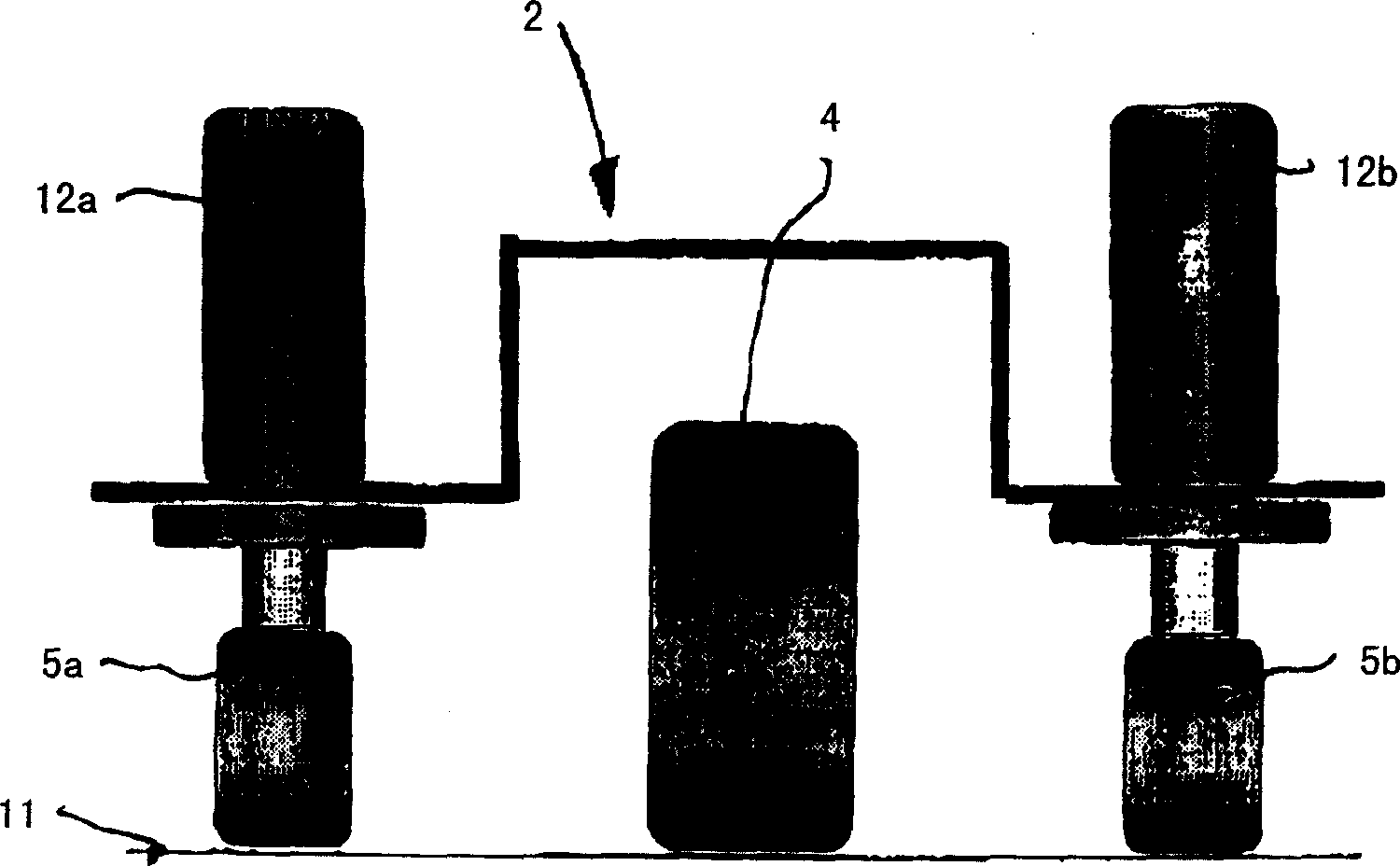

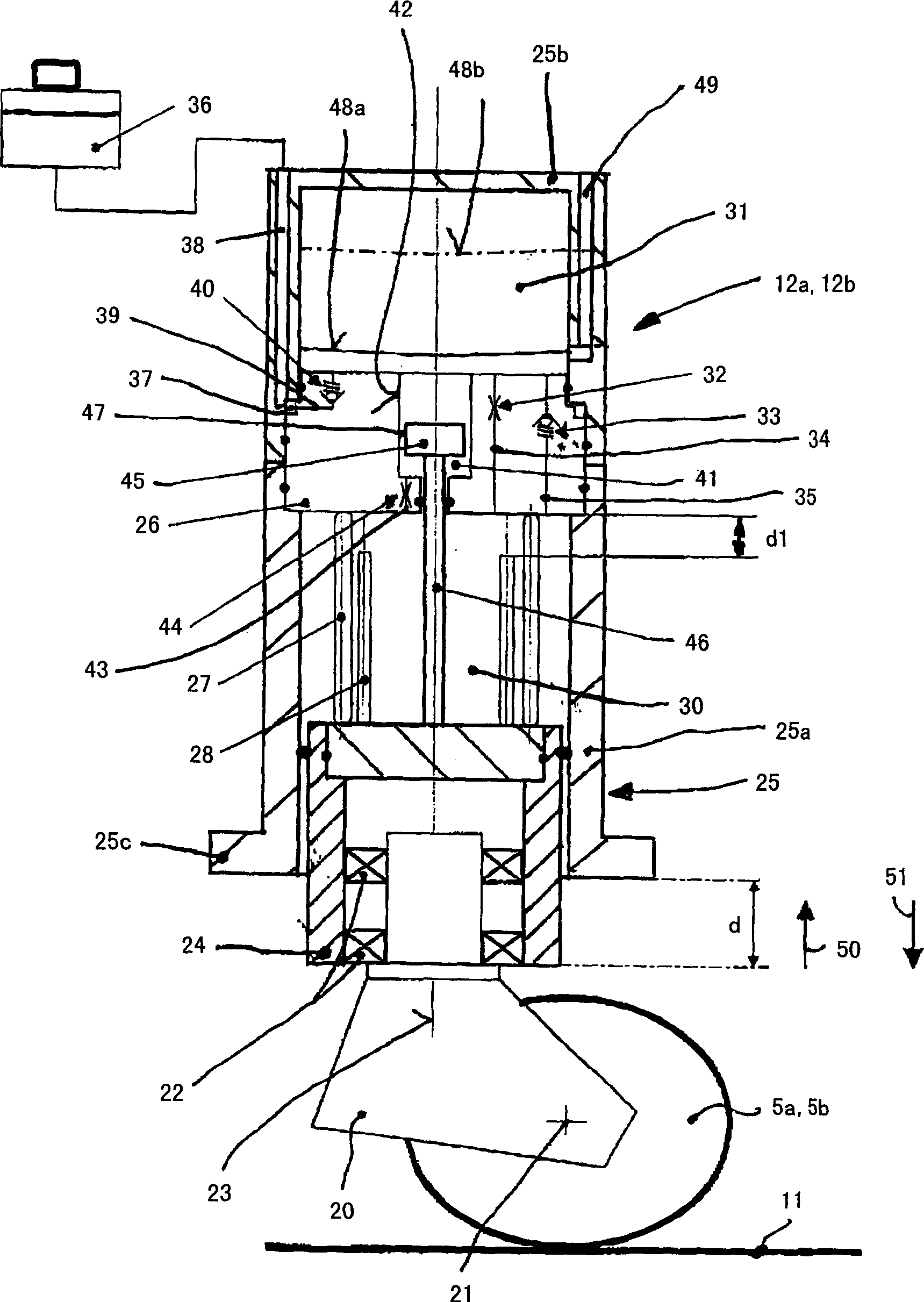

[0030] figure 2 gives figure 1 Schematic structure of the drive part 2 of the ground conveying device 1 . A steerable drive wheel 4 is secured to the drive part 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com