Hoe

A hoe and hoe handle technology, which is applied in the field of agricultural tools, can solve the problems of small welding area between the reinforcement rib and the hoe handle sleeve, low fixing strength between the hoe board and the hoe handle sleeve, and weak fixation between the hoe handle and the hoe board, etc. To achieve the effect of increasing the firmness of the fixation, the length of the welding circumference, and the firmness of the fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

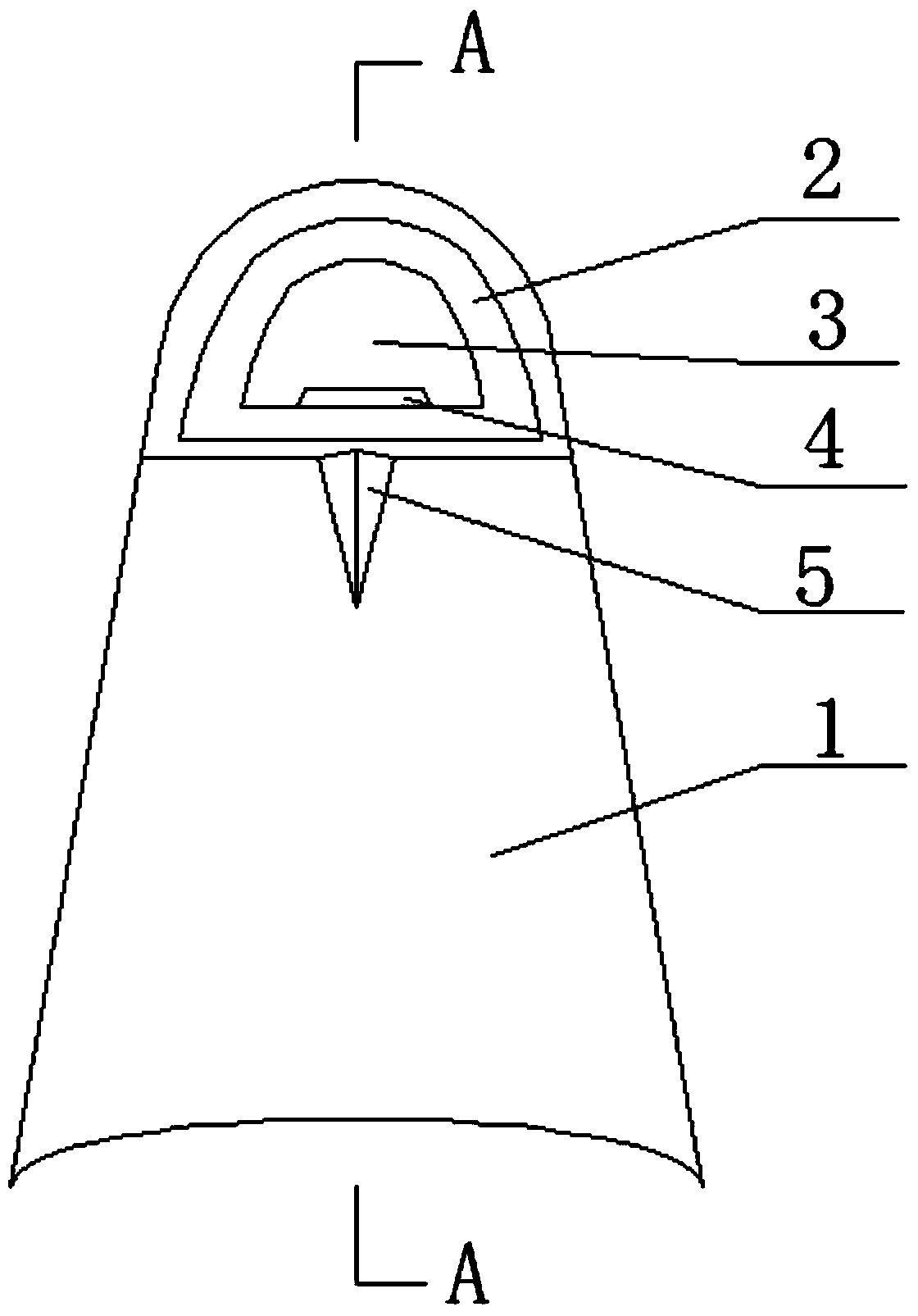

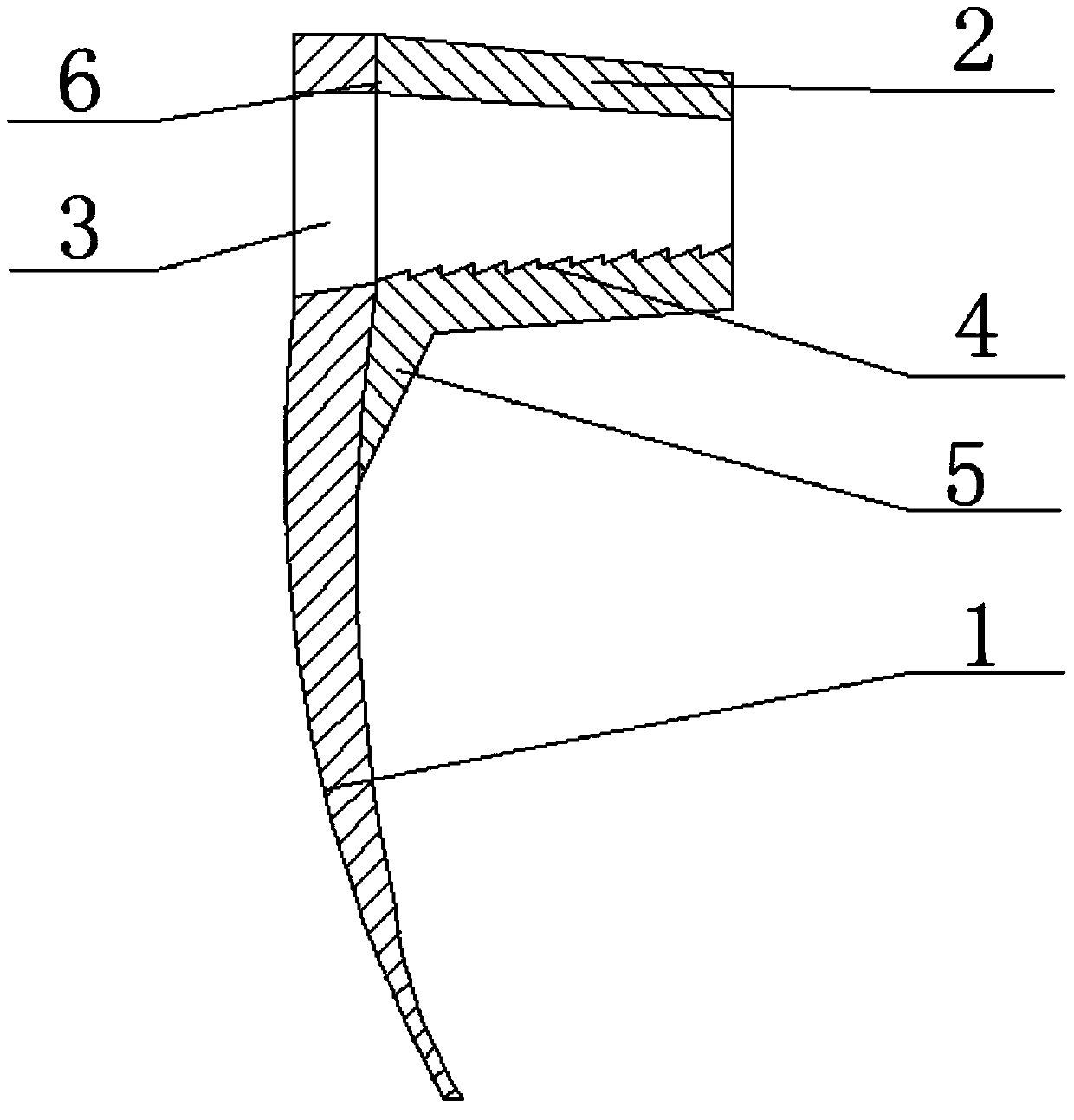

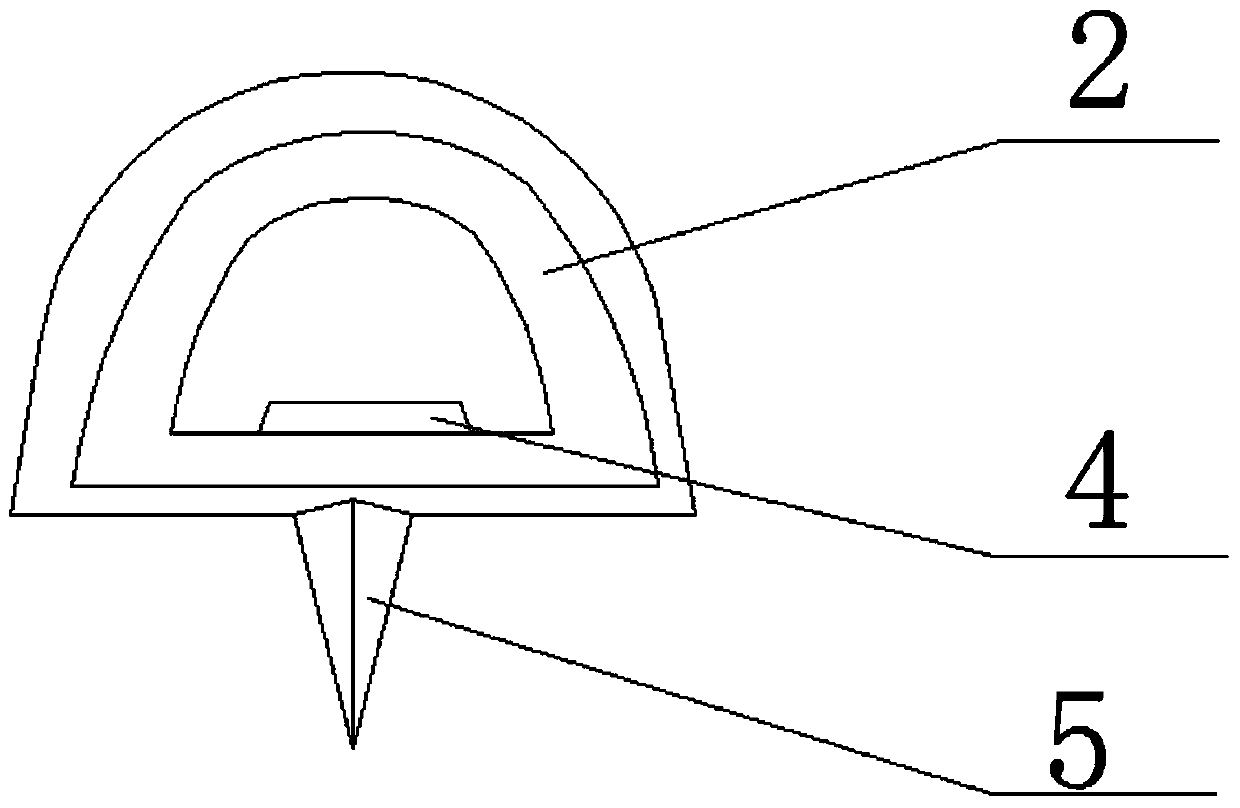

[0019] Such as figure 1 , figure 2 As shown, the present invention comprises a hoe board 1 and a hoe handle sleeve 2, and the inner hole of the hoe handle sleeve 2 is tapered gradually from one end to the other end of the hoe handle sleeve 2, and the hoe handle sleeve The end of the larger aperture of the tube 2 is the large aperture end 6, and the hoe plate 1 is provided with the same hoe plate hole 3 as the hole of the large aperture end 6 of the hoe handle sleeve 2, and the hoe handle sleeve The large-aperture end 6 of 2 is welded to the periphery of the hoe plate hole 3, and the hoe handle sleeve 2 is provided with a zigzag wedge 4 fixedly connected with the hoe handle sleeve 2, and the hoe handle sleeve 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com