Worm self-locking anti-loose type overload protective clamp

A technology of protective clips and worms, which is applied in the direction of clamping, clamping devices, manufacturing tools, etc., can solve problems such as easy loosening and difficult control of clamping force, and achieve the effects of preventing excessive clamping of workpieces, simple structure, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

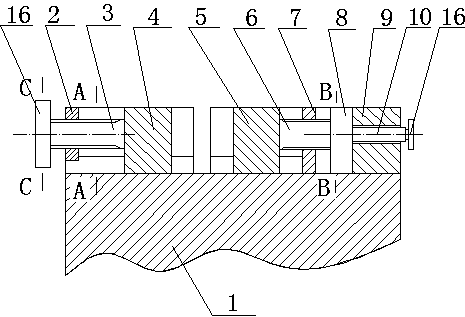

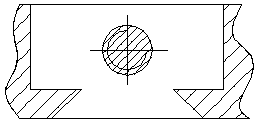

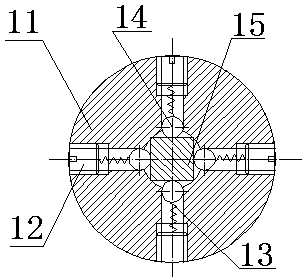

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the worm self-locking and anti-loosening overload protection fixture includes fixture seat 1, left fixing block 2, left screw rod 3, left clamping block 4, right clamping block 5, right screw rod 6, right fixing block 7, and fixture seat 1 There is a dovetail groove on the top, and a left fixed block 2 and a right fixed block 7 are arranged at both ends of the dovetail groove. Both the left fixed block 2 and the right fixed block 7 are provided with threaded holes, and the left clamping block 4 and the right clamping block 5 are all assembled in the dovetail groove on the fixture base 1, one end of the left screw rod 3 is fixedly connected with the left clamping block 4, the other end is meshed with the thread of the left fixing block 2, and one end of the right screw rod 6 is fixedly connected with the right clamping block 5 , the other end is assembled in the threaded hole of the right fixed block 7, and...

Embodiment 2

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the worm self-locking and anti-loosening overload protection fixture includes fixture seat 1, left fixing block 2, left screw rod 3, left clamping block 4, right clamping block 5, right screw rod 6, right fixing block 7, and fixture seat 1 There is a dovetail groove on the top, and a left fixed block 2 and a right fixed block 7 are arranged at both ends of the dovetail groove. Both the left fixed block 2 and the right fixed block 7 are provided with threaded holes, and the left clamping block 4 and the right clamping block 5 are all assembled in the dovetail groove on the fixture base 1, one end of the left screw rod 3 is fixedly connected with the left clamping block 4, the other end is meshed with the thread of the left fixing block 2, and one end of the right screw rod 6 is fixedly connected with the right clamping block 5 , the other end is assembled in the threaded hole of the right fixed block 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com