Flattening device for cloth

A cloth leveling and cloth roller technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of defective products, cloth wrinkles, affecting production efficiency, etc., to improve efficiency, prevent wrinkles, friction, etc. moderate force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be given below in conjunction with the accompanying drawings

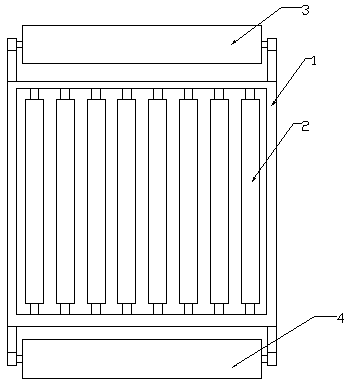

[0016] A cloth leveling device, the cloth leveling device comprises a leading cloth roller A3, a leading cloth roller B4, and a cloth leveler;

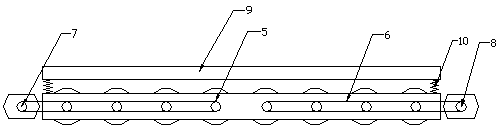

[0017] The cloth leveler includes several longitudinal cloth guide rollers 2, rotating outer frame 1, belt A5, belt B6, motor A7, motor B8, the number of the longitudinal cloth guide rollers 2 is a multiple of 2, and the several longitudinal cloth guide rollers The cloth guide rollers 2 are installed in the rotating outer frame 1 parallel to each other. The longitudinal cloth guide rollers 2 can rotate along their own longitudinal axes. area, the same number of longitudinal cloth guide rollers 2 in the two areas are respectively connected by belt A5, belt B6, motor A7, and motor B8, and the rotation directions of the motor A7 and motor B8 are opposite;

[0018] The leading cloth roller A3 and the leading cloth roller B4 are respectively loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com