Method and device for confirming effect of backlash countermeasures for press-formed products

一种确认装置、对策的技术,应用在机械压力/力控制、仪器、电数字数据处理等方向,能够解决无法恰当地评价成形条件变更的效果等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

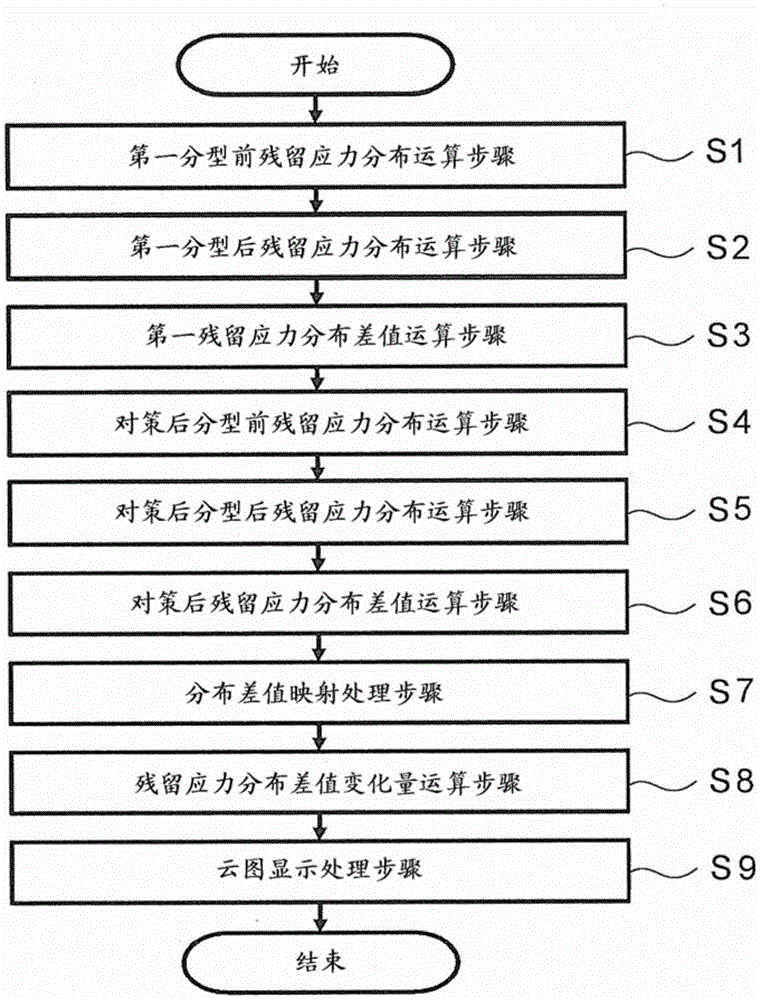

[0031] Embodiments of the present invention will be described based on the drawings.

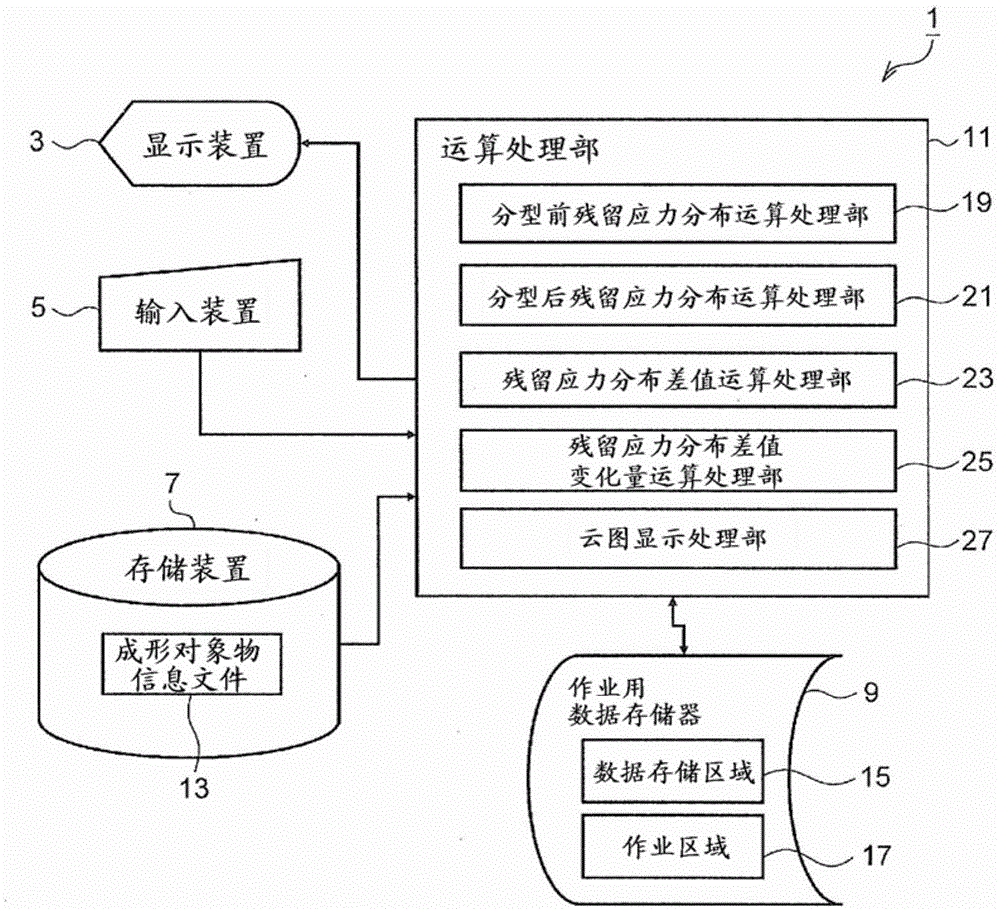

[0032] First, mainly based on figure 1 The configuration of the device for confirming the effect of the countermeasure against backlash 1 during press forming (hereinafter simply referred to as "the device for confirming the effect of the countermeasure against backlash 1") will be described with reference to the illustrated block diagram as appropriate.

[0033] In this embodiment, the recoil countermeasure effect confirmation device 1 is constituted by a PC (personal computer) and has a display device 3 , an input device 5 , a storage device 7 , a working data memory 9 , and an arithmetic processing unit 11 .

[0034] In addition, the display device 3 , the input device 5 , the storage device 7 , and the working data memory 9 are connected to the arithmetic processing unit 11 .

[0035]

[0036] The display device 3 is used for displaying calculation results and the like, and is constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com