Cages for Radial Roller Bearings

A roller bearing and cage technology, which is applied in the field of radial roller bearing cages, can solve the problems of unrestricted relative displacement and stable holding of rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

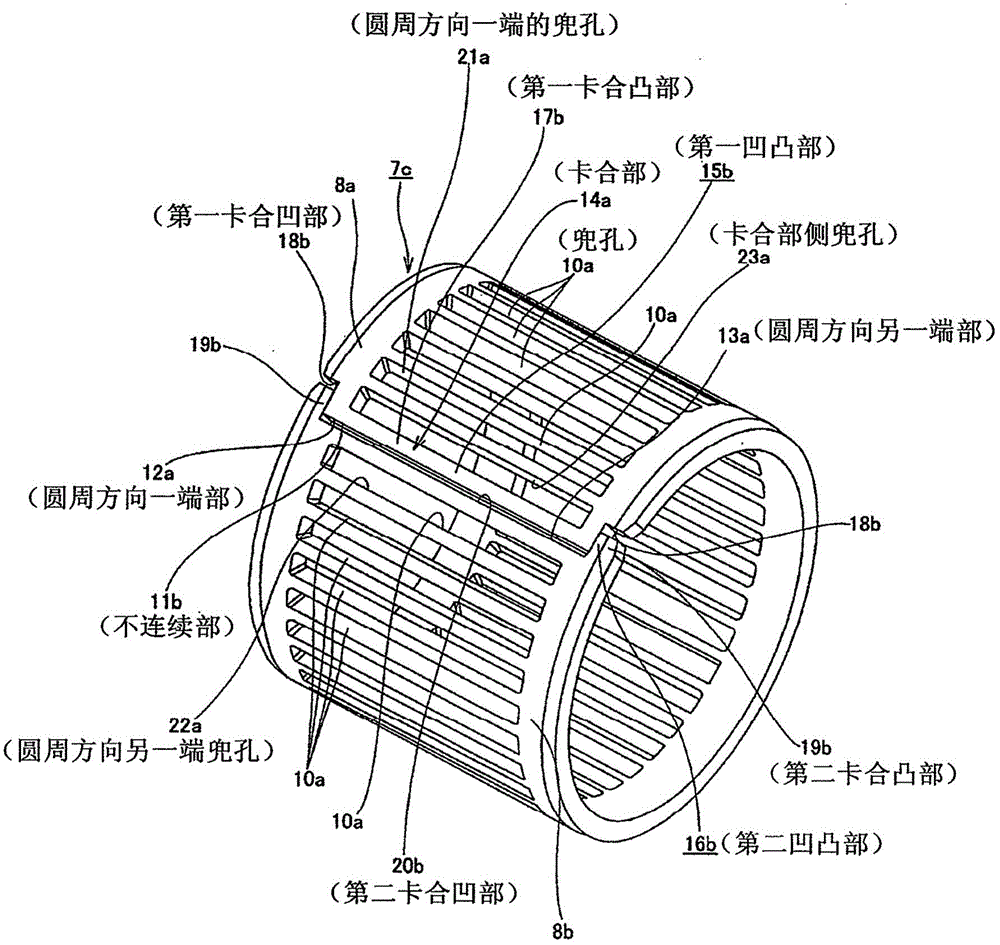

[0078] Embodiment 1

[0079] figure 1 It is a schematic diagram of the first example of the embodiment of the present invention. In addition, the present invention is characterized in that the cage 7c for a radial roller bearing has a discontinuous portion 11b in at least a part of the circumferential direction, and the end portions (one end portion 12a in the circumferential direction, one end portion 12a in the circumferential direction, and The other end portions 13a) are engaged with each other by the engaging portion 14a, and the structure of the engaging portion 14a is improved. Other structures include Figure 6-9 The existing structure shown is roughly the same as the conventionally known structure of the radial roller bearing cage, therefore, the description of the same components as the existing structure is omitted or simplified, and the characteristic parts of this example are as follows: Center is explained.

[0080] The radial roller bearing cage 7c of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com