A Pneumatic Pressurized Ladle Sliding Nozzle Mechanism

A sliding nozzle and steel ladle technology, which is applied in metal processing equipment, casting molten material containers, casting equipment, etc., can solve the problems that the popularization and application of pneumatic pressurization mechanism cannot promote the application of steel ladles in large quantities, so as to reduce the consumption of spare parts and eliminate human factors Influencing and reducing the effect of slide plate breakout production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

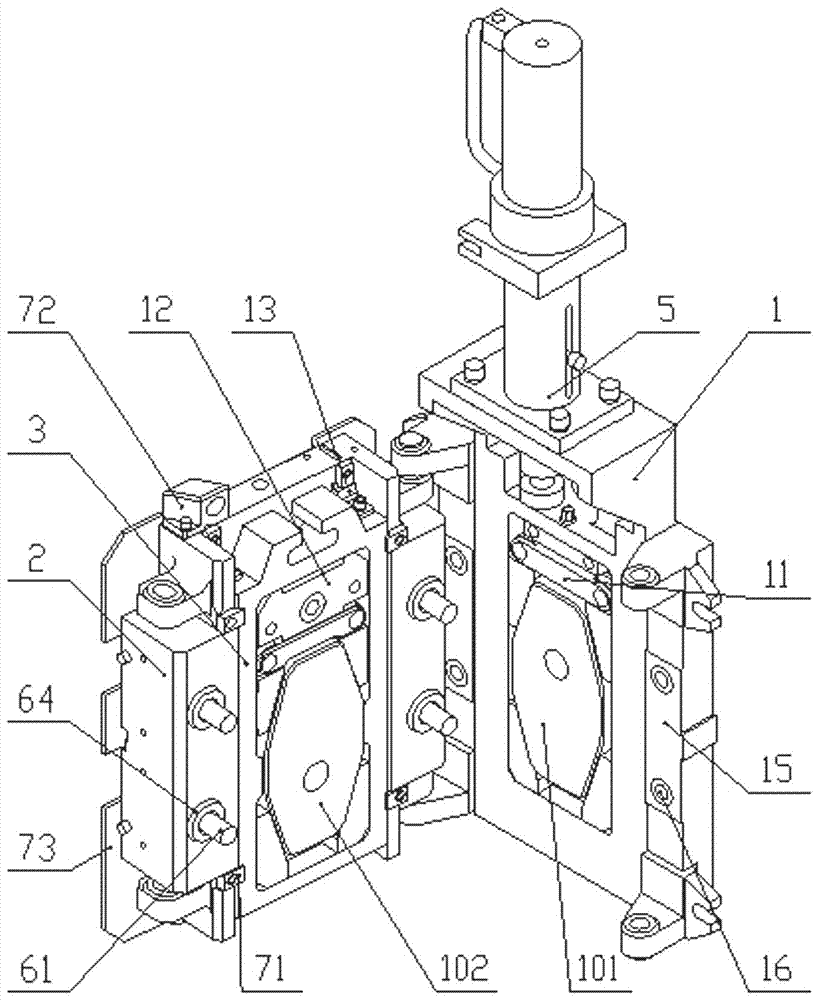

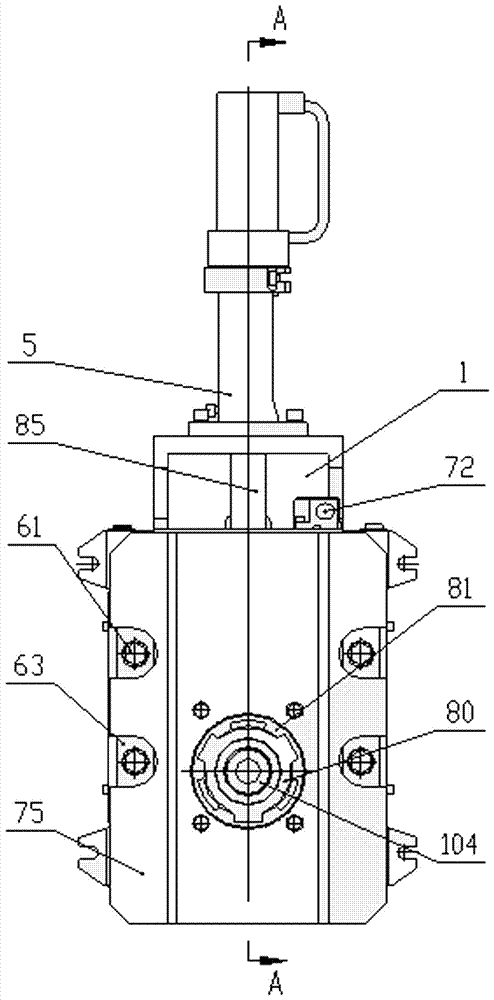

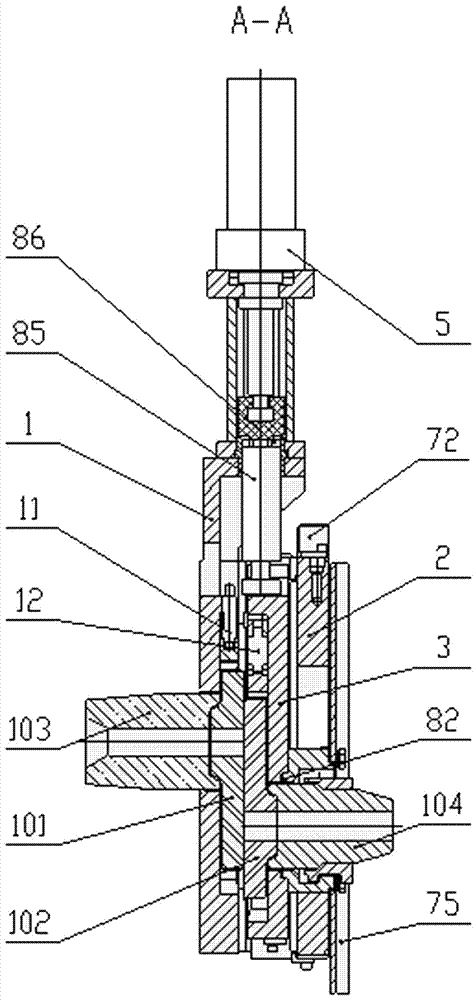

[0022] See attached Figure 1-9 , a pneumatic pressurized ladle sliding nozzle mechanism, including a fixed frame 1, an opening and closing frame 2, a sliding frame 3, a lower nozzle seat 81, a lower nozzle tensioner 80, an upper sliding plate 101, a lower sliding plate 102, an upper nozzle 103, a lower Nozzle 104, surface pressure bolts 61, driving device 5, surface pressure lock nuts 16 and surface pressure limiters 15 are symmetrically arranged on both sides of the fixed frame 1, spring chambers 60 are symmetrically arranged on both sides of the opening and closing frame 2, spring chambers 60 Spring pressing plate 63 is arranged inside, and surface pressure supporting column 64 is arranged at intervals below spring pressing plate 63, and several spring guiding columns 67 are arranged on the inner and outer sides of adjacent two sides pressing supporting column 64, and spring guiding column 67 is provided with spring 62; and the spring pressing plate 63 are all provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com