Stamped sealing arrangement for flat flanged joint

A sealing device, flat flange technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., to achieve the effect of small insertion height, material saving, and leakage rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

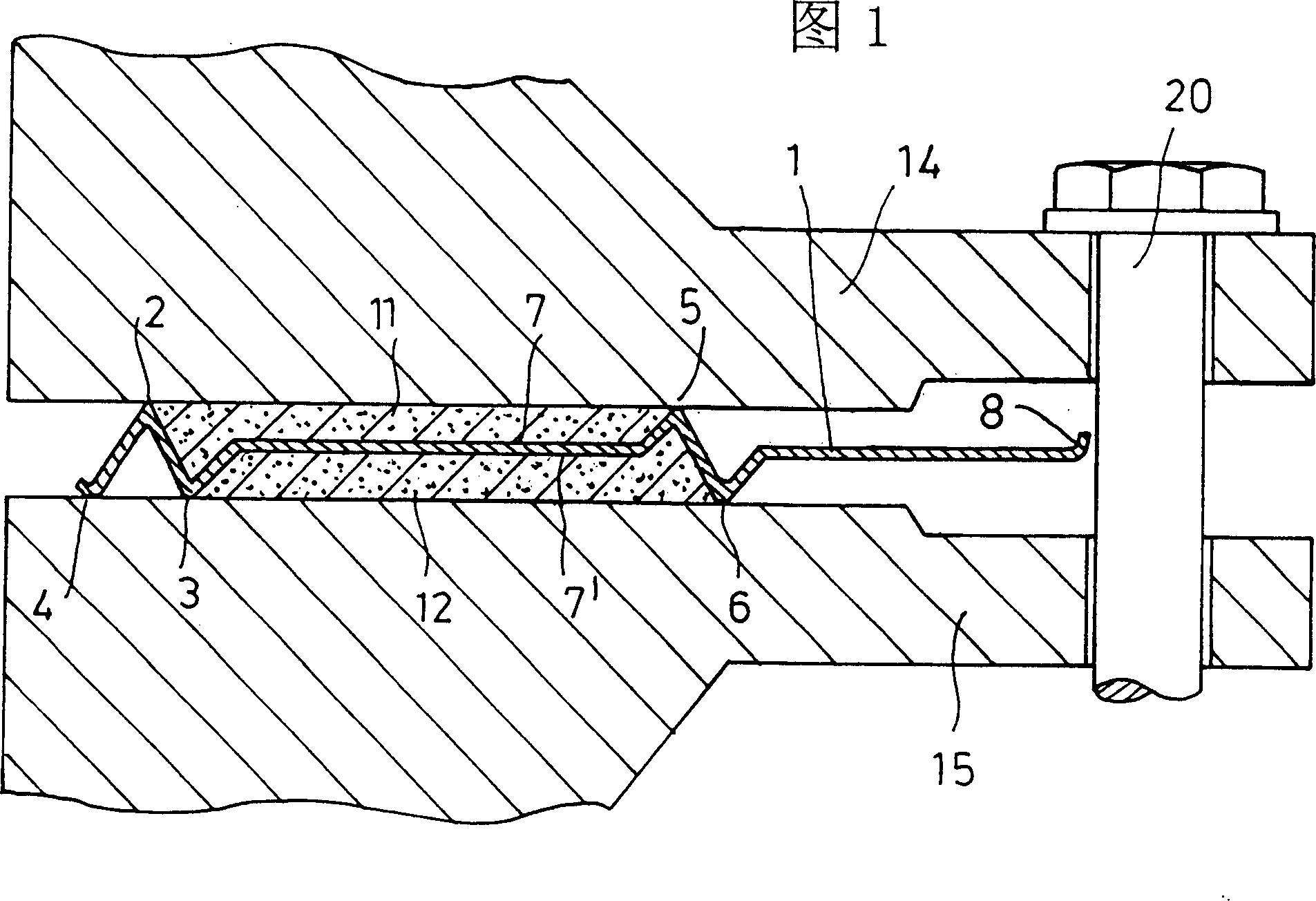

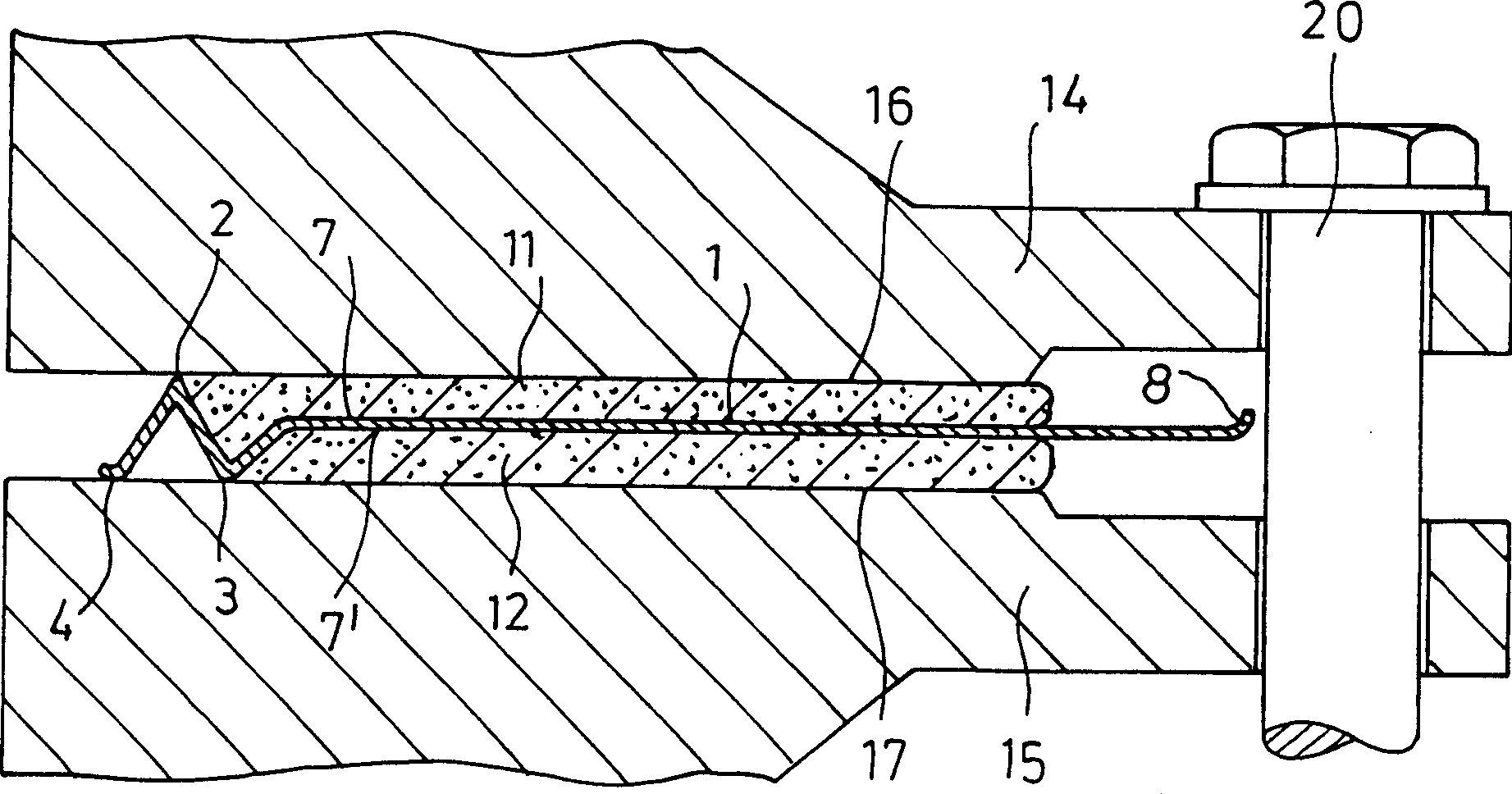

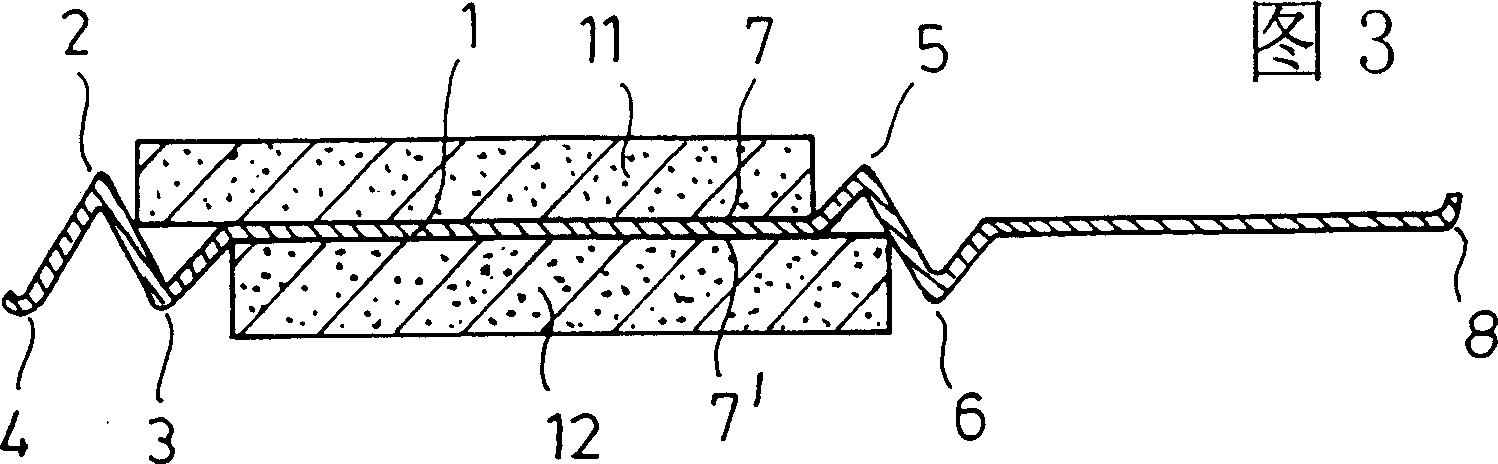

[0030] In these figures, the symbols have the following meanings:

[0031] 1 Part of the matrix

[0032] 2, 3, 4, 5, 6 and 9 ring teeth

[0033] 7, 7’ Load bearing surface for soft material supports

[0034] 8 Beading on outer edge of centering ring

[0035] 11, 12 Soft material supports

[0036] 14, 15 Flange part

[0037] 20 bolt local

[0038] In these figures it is assumed that the seal has been installed horizontally. Therefore, reference is made to the right or left part of the seal. Of course, the seal can be mounted in any desired orientation. If they were mounted vertically, then the upper and lower parts would have to be referenced. Due to the rotational symmetry of the seal, only the cross-section of the right part is always shown in the figures.

[0039] FIG. 1 shows the seal on an enlarged scale in a mounted state between flanges 14 and 15 . It consists of a base body 1 and two soft material supports 11 and 12 . The base body is preferably metallic, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com