Tank filler neck for a motor vehicle with improved sealing

A technology for motor vehicle and filling neck, which is applied in the field of filling neck of storage tank, can solve the problem that the discharge of hydrocarbons cannot be satisfied with the service life of motor vehicles, and achieves the effect of reducing emission and improving water impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

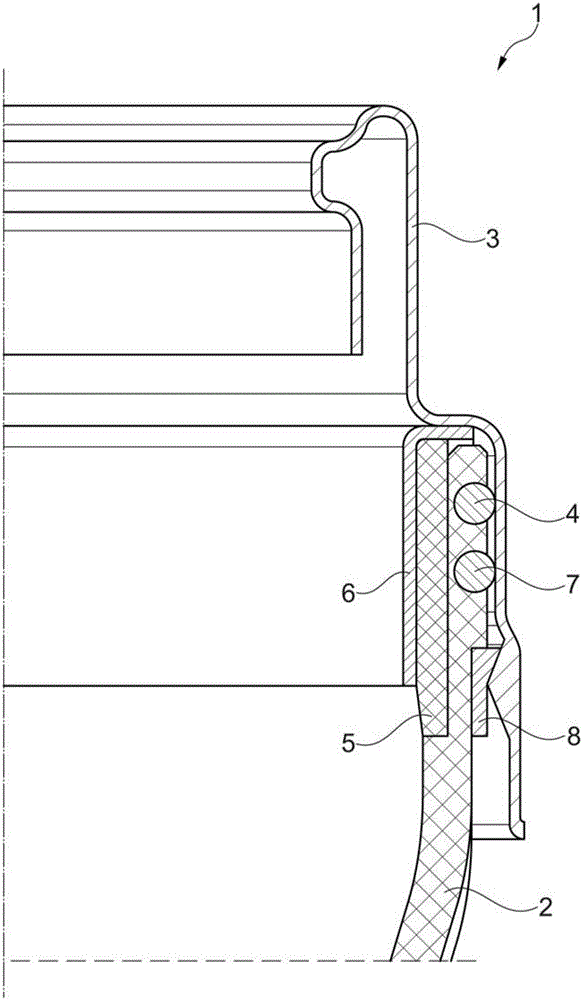

[0021] figure 1 Shown is a tank filling neck 1 for a motor vehicle comprising a plastic tube 2, a filling head 3 made of metal and surrounding the plastic tube 2 at its end, and made of an elastomer, in particular rubber And a first seal 4 arranged on the periphery between the plastic tube 2 and the filling head 3 . In this example, the filling head 3 is formed as a sheet metal shaped part, but in principle it can also be produced in a different way. Furthermore, the tank filling neck 1 comprises a first support ring 5 , which is arranged opposite the first seal 4 with respect to the plastic tube 2 and has a greater wall thickness than the filling head 3 . The first support ring 5 can consist, for example, of metal or plastic, in particular fiber-reinforced plastic.

[0022] The fixing of the filling head 3 on the plastic tube 2 is stabilized by using a first support ring 5 . Due to the fact that the wall thickness of the first support ring 5 is greater than that of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com