Angle grinding seat

An angle and angle adjustment technology, used in grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of low angle grinding accuracy, low work efficiency, and high grinding efficiency, and achieve high grinding efficiency, improve grinding efficiency, and improve grinding. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

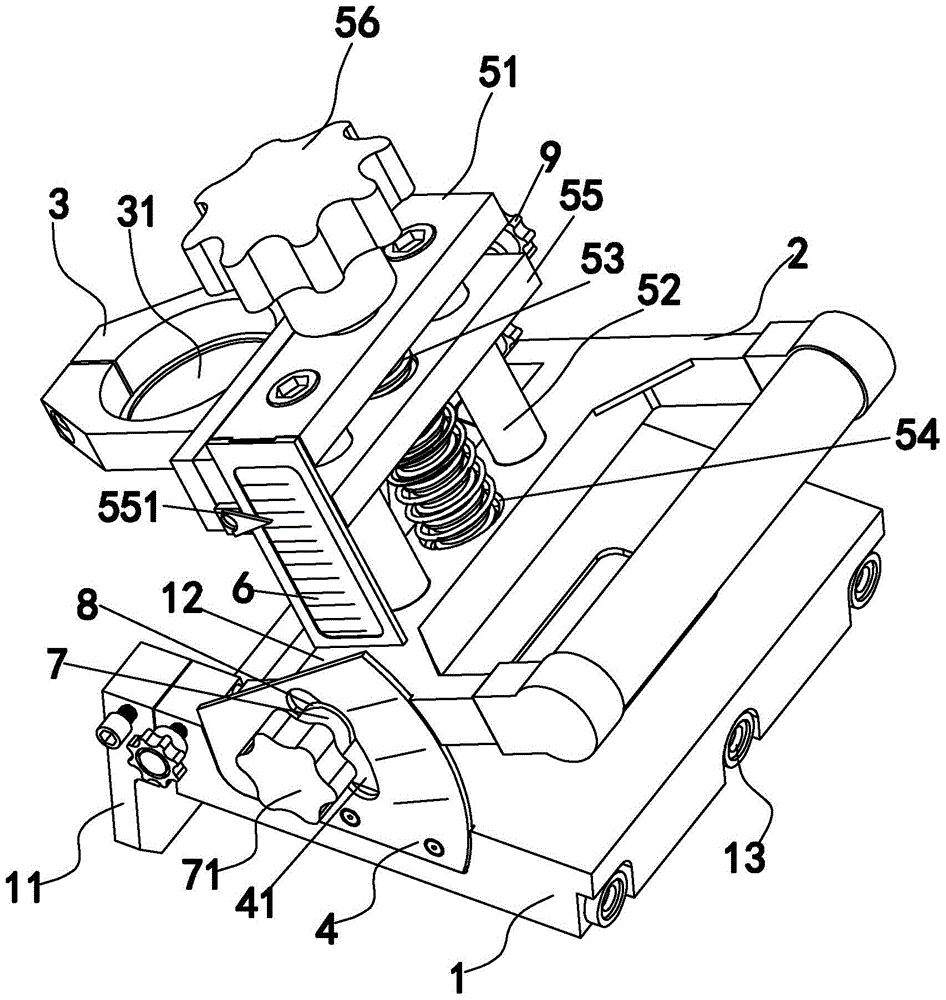

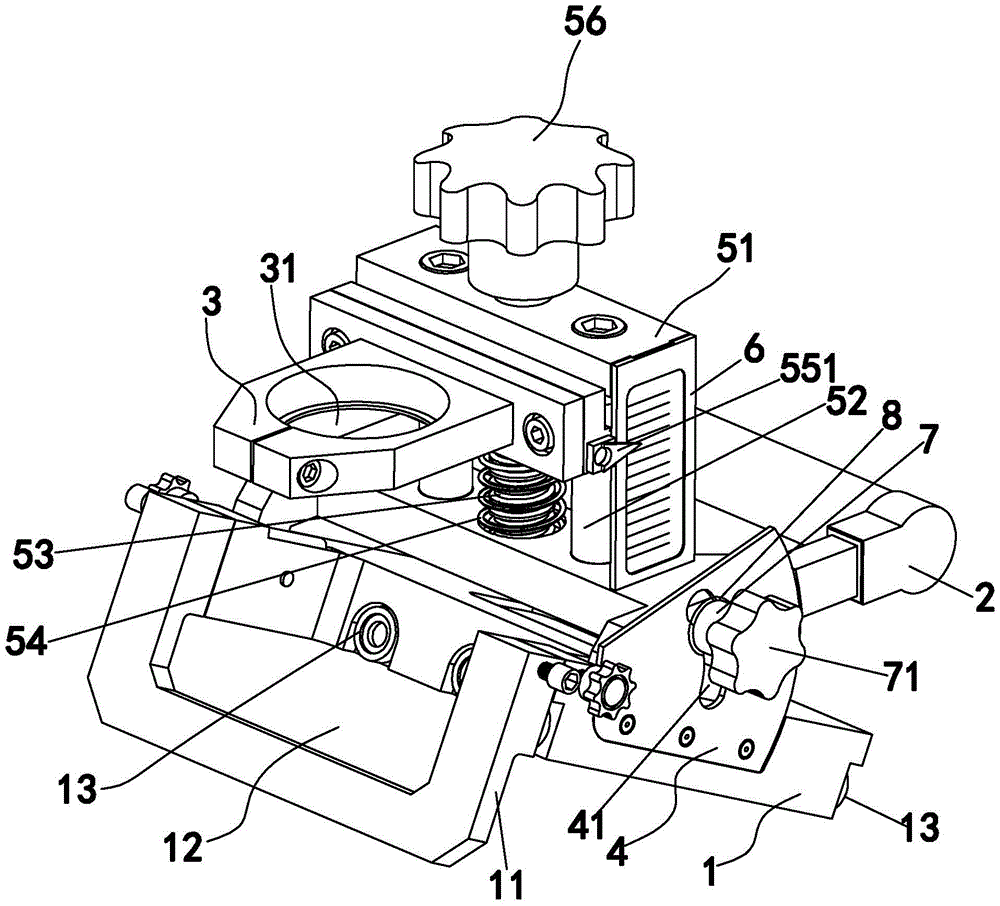

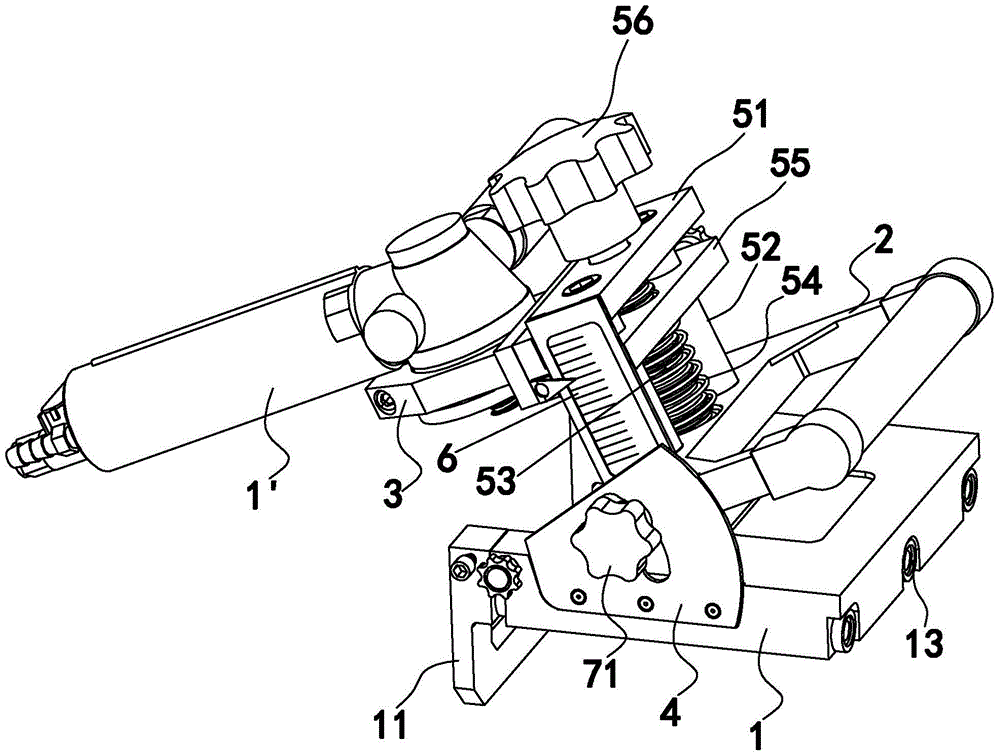

[0014] refer to figure 1 and figure 2 , the present embodiment discloses an angle grinding seat, including a sliding table 1, an angle adjusting seat 2, a clamping seat 3 and an angle dial 4, and the front side of the sliding table 1 is provided with a 1. The positioning block 11 that enables the sliding table 1 to position and walk along the edge line of the grinding workpiece. The angle adjustment seat 2 is hinged to the upper part of the sliding table 1 through a pin shaft and can rotate up and down along the sliding table 1. Adjust the angle of rotation between the angle adjustment seat and the sliding table to obtain the required grinding angle. The clamping seat 3 is located at the front upper part of the angle adjustment seat 2, A height adjustment device is provided, and the height adjustment device includes a support positioning block 51,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com