Telescopic screwdriver with movable screwdriver bit

A screwdriver, telescopic technology, used in screwdrivers, wrenches, wrenches, etc., can solve problems such as no way to unscrew, unfavorable repairing machines, and increase work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

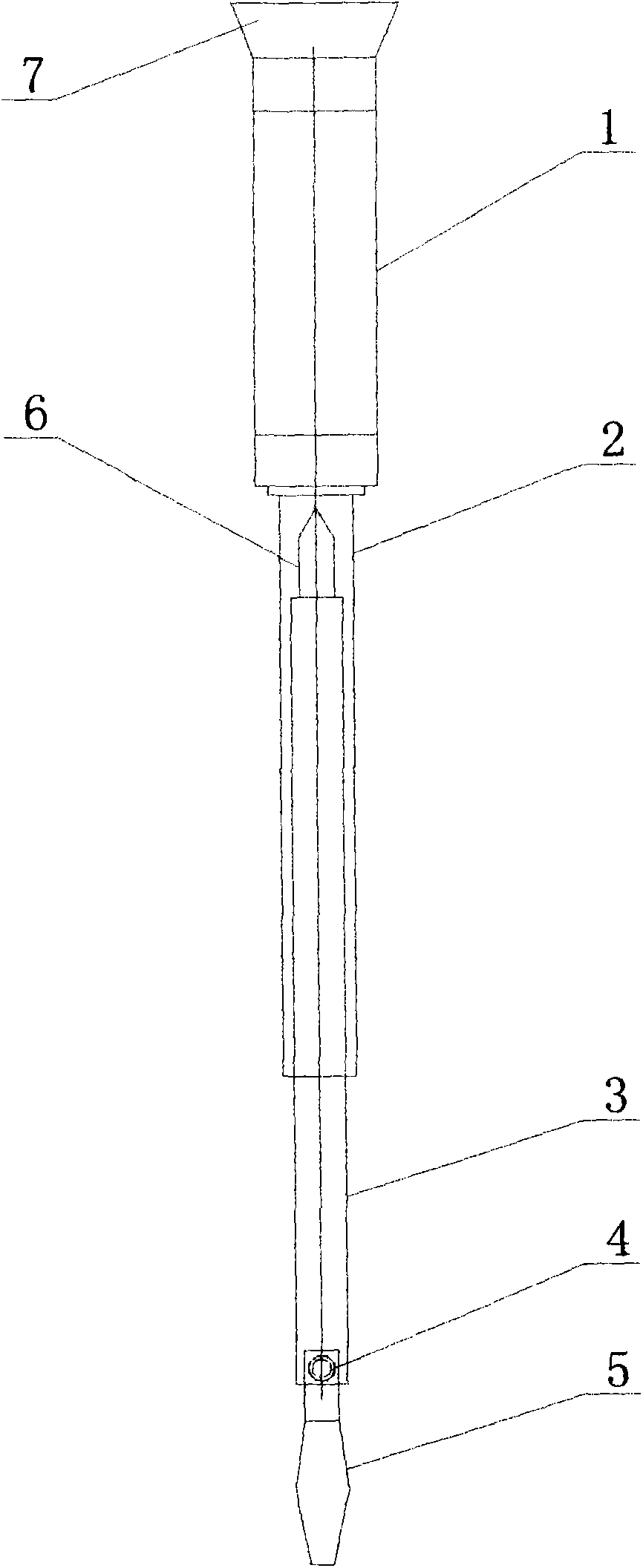

[0016] like figure 1 As shown, a telescopic screwdriver with a movable cutter head described in this specific embodiment includes a screwdriver body, and the screwdriver body includes a handle 1, and one end of the handle 1 is provided with a hollow female knife rod 2. Internal thread is provided on the inner wall of the inner cavity of the cavity mother knife rod 2; The thread matches the external thread, and the sub-tool bar 3 is twisted and inserted in the cavity mother bar 2; one end of the sub-tool bar 3 is provided with a plum blossom cutter head 6, and the other end of the sub-tool bar 3 is hinged with a movable knife Head 5, the movable cutter head 5 is fixed by bolt 4.

[0017] A tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com