Slotted cam conveying mechanism

A technology of conveying mechanism and groove cam, which is applied in the direction of conveyor, transportation and packaging, can solve the problem that the spring cannot achieve stable and continuous work, and achieve the effect of stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

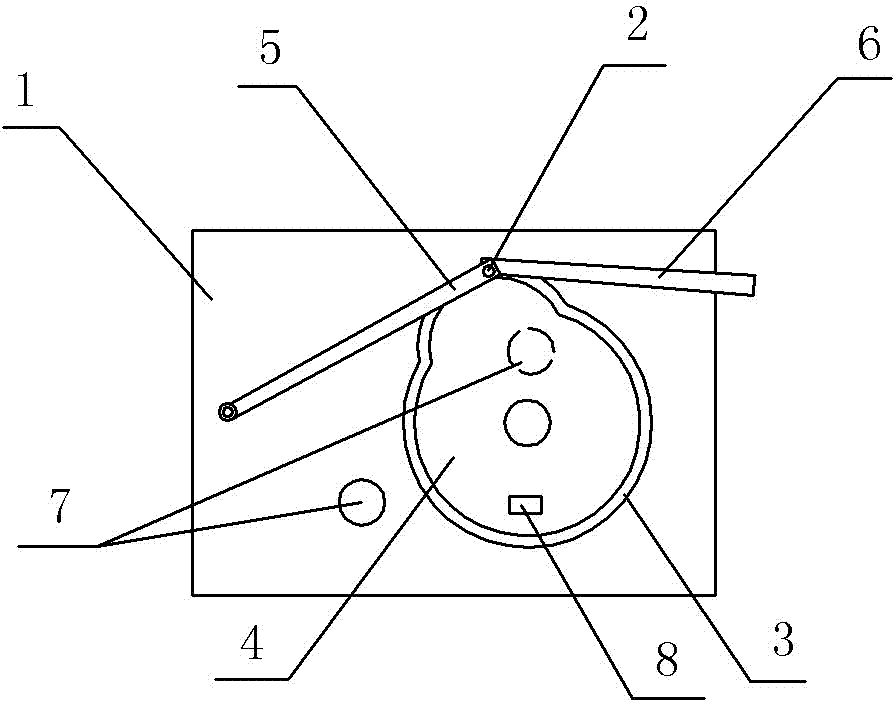

[0011] like figure 1 As shown, a conveying mechanism with a grooved cam 4 in this embodiment includes a base 1, a follower 2, a cam 4 with a guide groove 3, a connecting rod 5 and a push rod 6, and one end of the connecting rod 5 is connected to On the base 1, the other end is connected with the push rod 6, one end of the follower 2 is arranged on the end of the connecting rod 5 close to the push rod 6, and the other end is slidably connected in the guide groove 3 of the cam 4, the base 1 is provided with a plurality of cam mounting holes 7, and a temperature sensor 8 is provided on the cam.

[0012] One end of the connecting rod 5 is connected to the base 1, and the follower 2 on the connecting rod 5 moves along the guide groove 3 of the cam 4 to realize the rotation of the connecting rod 5. Because the push rod 6 is connected with the connecting rod 5, the pushing The rod 6 can swing back and forth within a certain range and can be used to push materials. The base is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com