Fresh-keeping film hand cutter

A technology of plastic wrap and sealing cover, which is applied in the field of plastic wrap hand cutters, can solve the problems of poor use effect of plastic wrap, heavy workload of plastic wrap, and poor practical performance, so as to achieve good practical performance, strong practical performance, and improved use effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

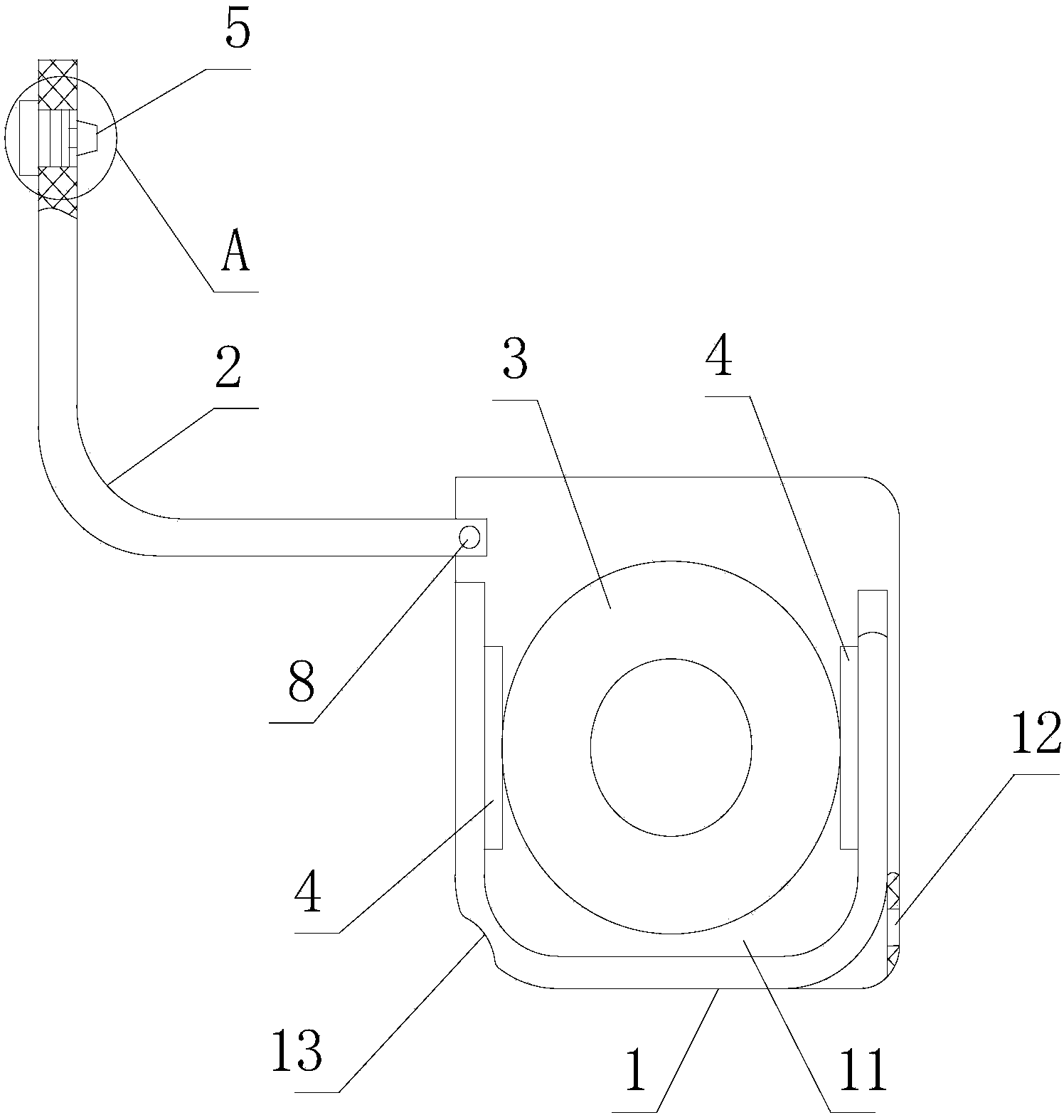

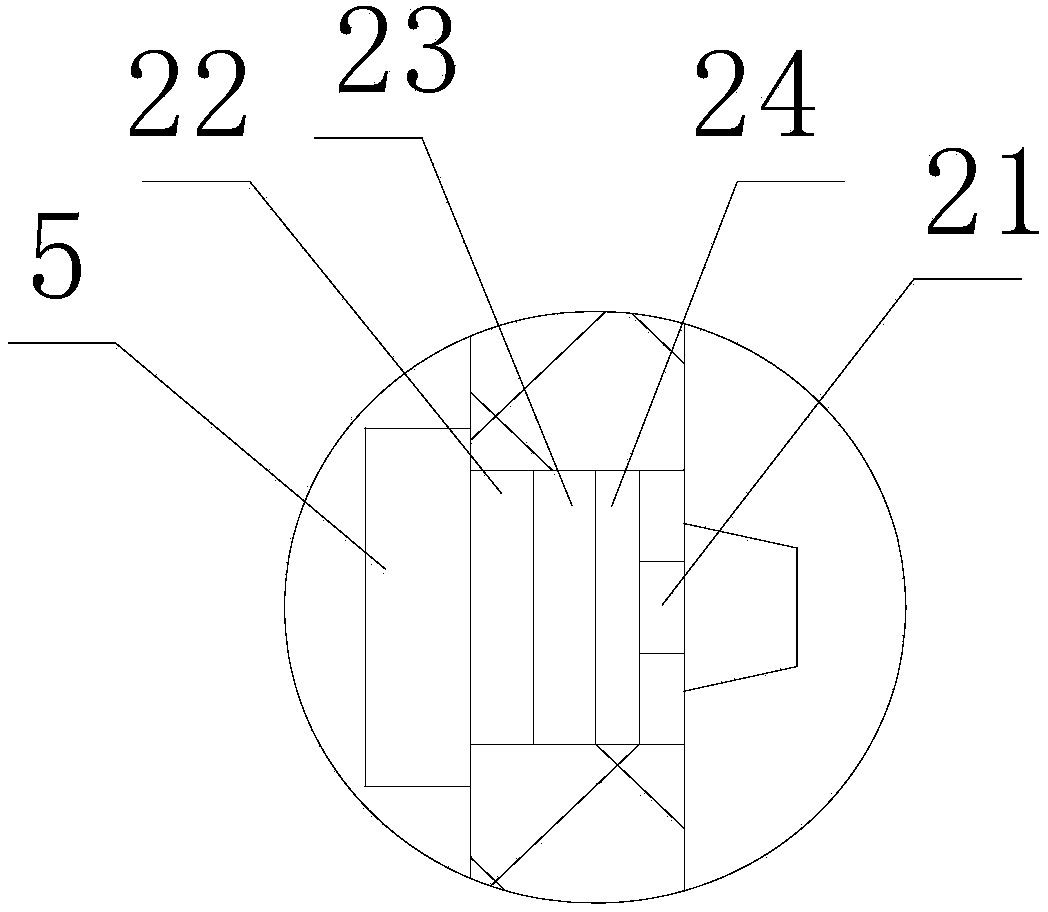

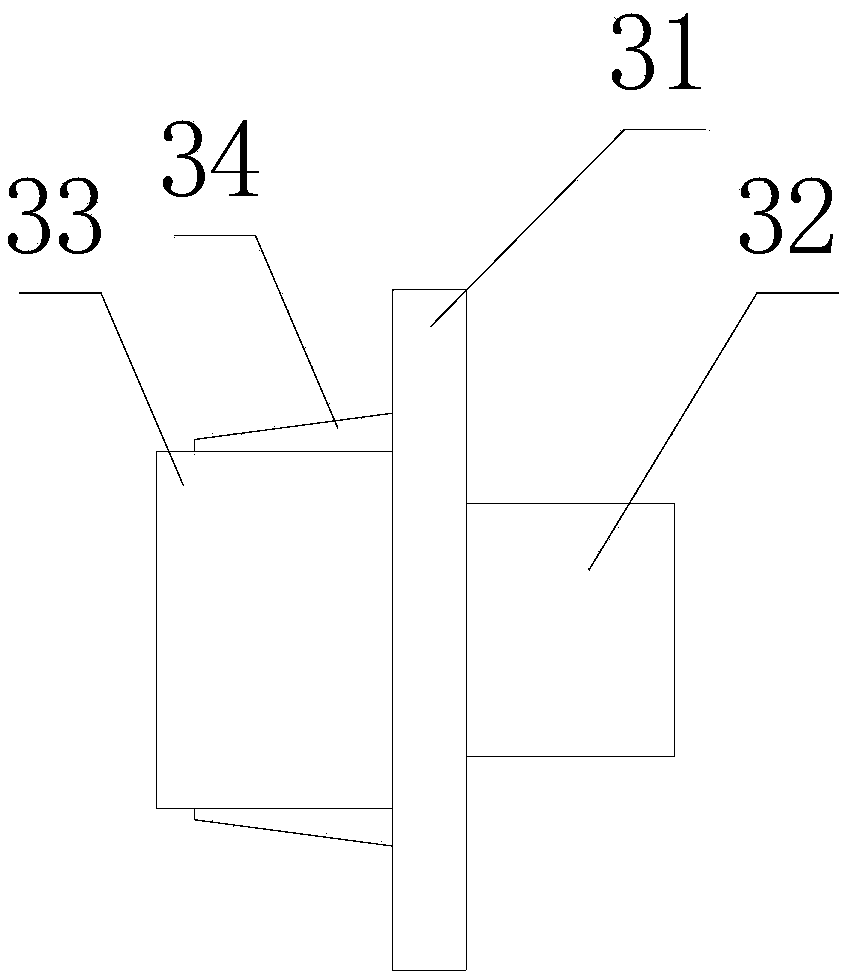

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown: a hand cutter for plastic wrap, including a body 1 with a cavity 11 and a sealing cover 2 that is rotatably connected to the body 1 . Body 3, the inner side wall of the cavity 11 is provided with at least one set of slots 4 for fixing the rotating body 3 in the cavity 11, and the outlet of the fresh-keeping film is formed between the sealing cover 2 and the body 1. material gap, the sealing cover 2 is movably connected with a cutting assembly 5 that cuts off the fresh-keeping film, and the cutting assembly 5 includes a slider 51 that is slidably connected in the guide rail, and a cutter 52 fixed at the bottom of the slider 51. Knife 52 is V-shaped on slide block 51, and at least one side wall of described cutting knife 52 is provided with cutting blade 521, and described rotating body 3 comprises the card 31 that cooperates with slot 4, is fixedly connected on the card 31 and uses. For connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com