Transparent PP (Polypropylene) material for automobile radiator and preparation method thereof

A car water tank and transparent technology, applied in the field of plastic modification, can solve the problems of high requirements and high price, and achieve the effect of low material cost, good transparency and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with embodiments.

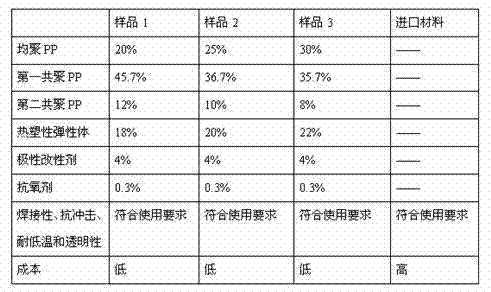

[0016] The technical solution of this embodiment is: a transparent PP material for automobile radiators, which is composed of the following components in mass percentage: 20%-40% of homopolymerized PP, 20%-50% of the first copolymerized PP, 20%-50% of the second copolymerized PP 10%-20%, thermoplastic elastomer 8%-25%, polar modifier 2%-8%, antioxidant 0.1%-0.3%.

[0017] Wherein, the first copolymerized PP adopts a medium-impact copolymerized PP with a melt index of 30-60 g / 10min.

[0018] Wherein, the second copolymerized PP is transparent random copolymerized PP.

[0019] Wherein, the homopolymer PP adopts a homopolymer PP with a melt index of 22-31 g / 10 min and an isotacticity of 94.5-97% b.m.

[0020] The preparation method of any one of the above-mentioned transparent PP materials for automobile water tanks provided by this embodiment includes the following steps: fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com