A laser-activatable lds antenna coating

A laser activation and coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of high cost, difficulty in meeting the requirements of laser activatable materials, high production costs, etc., to reduce raw material costs, easy laser engraving, and excellent boiling resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

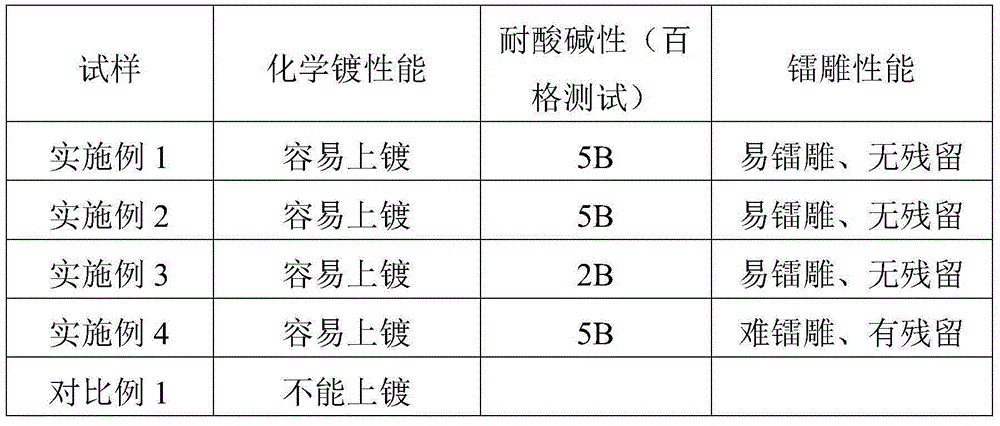

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0024] In some embodiments, the laser-activatable LDS antenna coating comprises a resin material and an organometallic complex, the organometallic complex includes an outer organic layer and an inner layer containing a metal substance, and the outer organic layer is exposed to laser light Can be gasified. Due to the addition of organometallic complexes to the paint components, the coating formed by the paint is irradiated by the laser, and the organic matter in the outer layer of the organometallic complex is vaporized, while the metal substance remains in the coating, thus forming in the laser irradiated part. metal wiring layer. Preferably, the organometallic complex is one or a mixture of two or more of silver complexes, copper complexes, iron complexe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com