Simulation and optimization method of cutter suction dredger cutter cutting soil based on pro/e

A cutter suction dredger and optimization method technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of complex parametric modeling, complex design and production process, etc. Optimizing the effect of the reamer model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

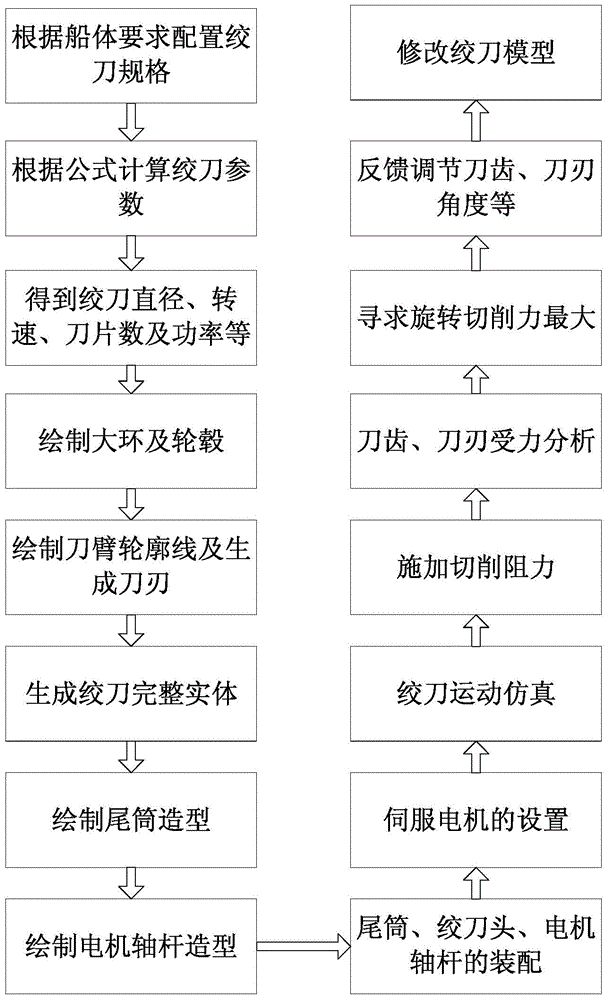

[0050] Such as figure 1 As shown, the Pro / E-based simulation optimization method of cutter suction dredger cutter cutting soil includes the following steps:

[0051] 1. In the modeling process of the dredger cutter, the cutter parameters of the dredger are needed. First, configure the cutter specifications and calculate the cutter parameters according to the requirements of the dredger hull. Different dredger models are different. Therefore, the configured reamer models are also different. Different reamer models have different reamer parameters. Configure the reamer according to the dredging volume of the dredger designed, and then calculate the reamer parameters. The main parameters of the reamer are the diameter of the reamer. , reamer speed and reamer power, etc., the parameters are calculated as follows:

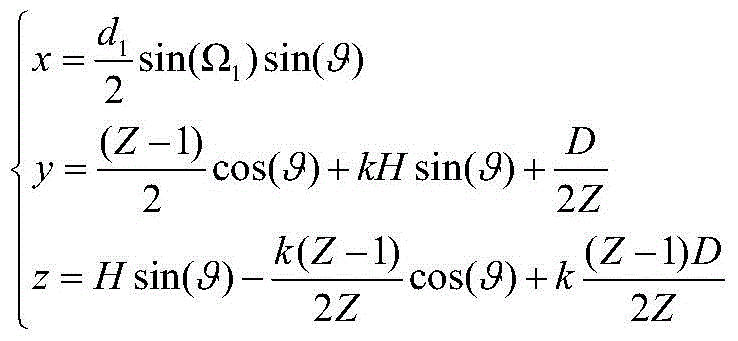

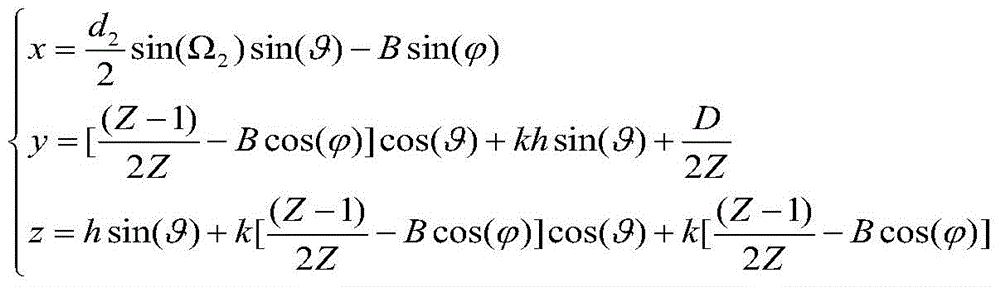

[0052] The calculation formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com