Frictional heating insoles

A technology of friction heating and insoles, which is applied in footwear, clothing, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

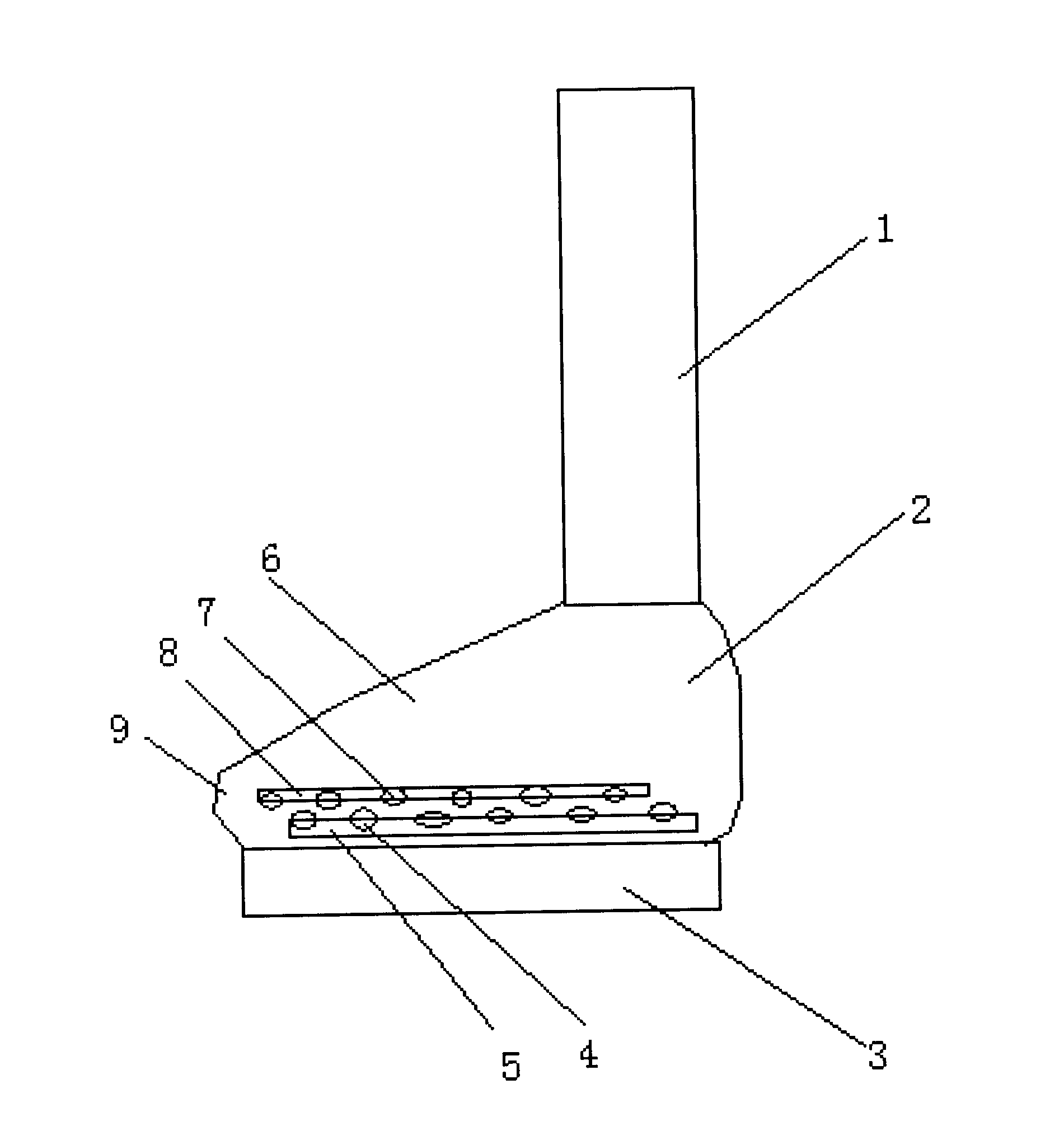

[0009] exist figure 1 In the shown embodiment, upper (1), heel (2), sole (3), lower friction plate (4), lower insole (5), shoes (6), upper friction plate (7), upper Insole (8), toe cap (9).

[0010] Implement the frictional heating insole of the present invention, comprising shoes (6), upper of a shoe (1), heel (2), sole (3), toe cap (9) connected in sequence, the shoe sole (3) is equipped with a lower insole (5), The lower friction plate (4) is installed on the surface of the lower shoe-pad (5), the upper shoe-pad (8) is installed above the lower shoe-pad (5), and the upper friction plate (7) is installed on the bottom surface of the upper shoe-pad (8). The lower friction plate (4) installed on the surface of the lower insole (5) and the upper friction plate (7) installed on the bottom surface of the upper insole (8) can have multiple.

[0011] Implement the friction heating insole of the present invention, when walking, use the movement of the sole of the foot to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com