Novel spray gun switch triggering mechanism

A switch trigger and spray gun technology, applied in spray devices, single handheld devices, etc., can solve the problems of interruption of the spray painting process, reduced work efficiency, easy to fall off, etc., and achieve the effect of prolonging service life and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

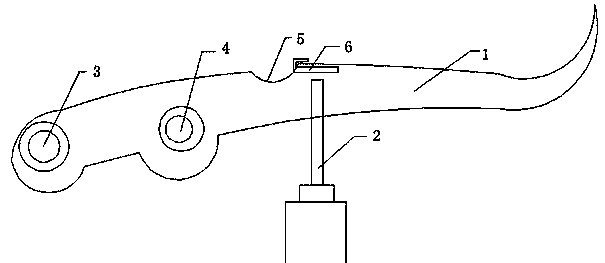

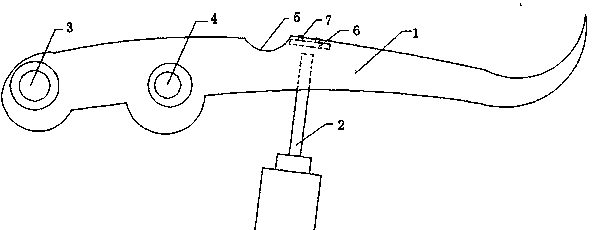

[0020] figure 2 It is a structural schematic diagram of an embodiment of the present invention.

[0021] like figure 2 Shown: a new spray gun switch trigger mechanism, including a sliding handle 1 with a U-shaped structure in cross section, a gasket 6 on the inner bottom surface of the sliding handle 1, a trigger switch and a thimble 2 arranged on the upper part of the trigger switch. The thimble 2 The end of the washer 6 is set corresponding to the gasket 6 and is in intermittent contact. In this implementation, the gasket 6 is a thin plate, and the end of the gasket 6 facing away from the thimble pin 2 is also provided with a fixing column 7. The fixing column 7 passes through the bottom surface of the sliding handle 1 and is fixed on the bottom surface of the sliding handle 7 .

[0022] In this embodiment, the gasket 6 and the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com