A processing device and method for improving surface roughness and flatness of large external threads

A surface roughness and processing device technology, which is applied in the field of mechanical processing, can solve the problems of complex and difficult processing of large external thread roughness and flatness, and achieve the effects of reducing tool marks, improving work efficiency, and saving lathe resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

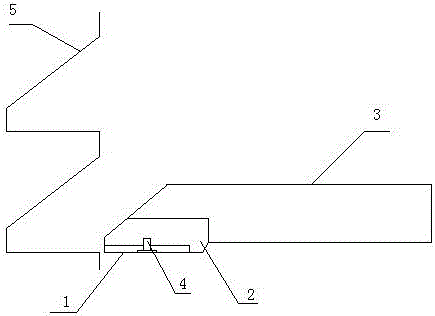

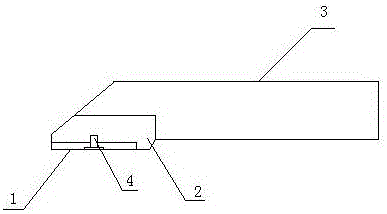

[0010] The following for the attached figure 1 , 2 The present invention is further analyzed: as attached figure 1 , 2 As shown, a processing device and method for improving the surface roughness and flatness of large external threads, the processing device is composed of a scraper head 2, a processing blade 1, and a cutter body 3. The shape of the scraper head 2 needs to be completely similar to that of the external thread 5 to be processed. The knife body 3 is fixedly connected with the scraper head 2 . The processing blade 1 is fixedly connected with the scraper head 2 through a pressing nail 4 . A processing method for improving the surface roughness and flatness of large-scale external threads is as follows: the cutter body 3 is horizontally mounted on the CNC lathe tool holder, the scraper head 2 is facing the surface of the external thread 5 to be processed, and the offset X, Z At the same time, adjust the horizontal position of scraper head 2 within 0.01mm and kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com