Mechanical claw in food industry

A technology of food industry and mechanical claw, applied in the field of mechanical claw, it can solve the problems of slipping, damaged samples, and difficult control of fingers and claws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

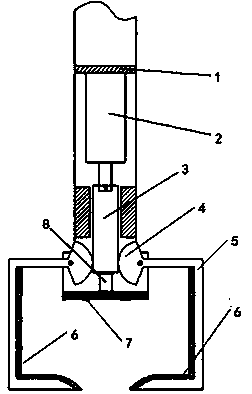

[0012] Embodiment 1: a kind of mechanical claw used in the food industry according to the present invention, such as figure 1 As shown, the fixed mechanism 1 arranged inside the mechanical arm is connected with a telescopic mechanism, the lower end of the telescopic mechanism 2 is connected with a rack 3, and the two sides of the rack 3 are provided with limit mechanisms, and the bottom of the limit mechanism is opposite to each other. Two sector gears 4 are provided, and the two sector gears 4 mesh with the rack 3 on opposite sides of the rack 3, and the two sector gears 4 are fixedly connected with opposite fingers 5 , the bottom of the rack 3 is provided with a sensor 8, the telescopic mechanism 2 is provided with a controller, the controller and the sensor 8 are connected to the control system, and the control system obtains the data transmitted by the sensor 8 The strength of the claws, thereby controlling the controller, controlling the expansion and contraction of the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap